Polishing method and device based on heat rheological material

A polishing device and thermo-rheological technology, applied in grinding/polishing safety devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of low automation, high processing efficiency, low polishing efficiency, etc., and achieve automation High degree of effect at low cost and high material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

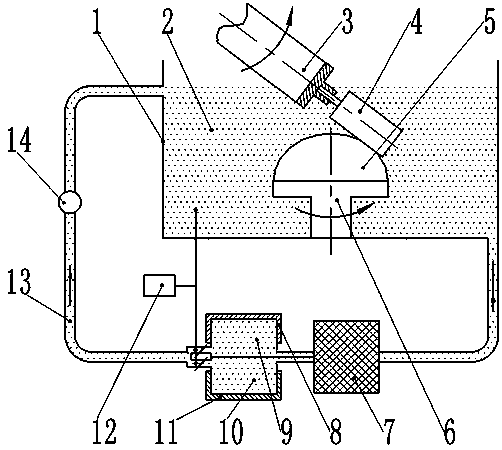

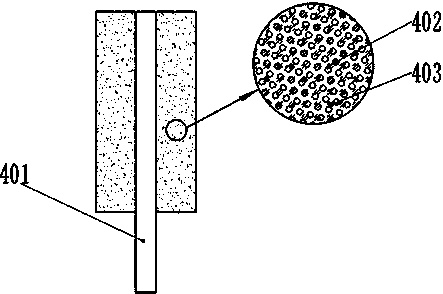

[0026] refer to figure 1 and figure 2 , a polishing method based on photorheological materials in this embodiment, used in combination with existing polishing equipment, includes the following steps but is not limited to the following steps, and can be adjusted according to actual production conditions:

[0027] 1) Fix the workpiece 5 on the fixture 6 of the driving shaft located in the polishing pool 1, and then fill the polishing pool 1 with the heat carrier 2;

[0028] 2) Start the heating medium circulation system, and use the temperature control device 12 to control the temperature of the heating medium 2, so as to adjust the stiffness of the thermorheological elastomer grinding head 4 to meet the process requirements;

[0029] 3) Adjust the fixture 6 and control the movement of the polishing spindle 3 at the same time, so that the thermo-rheological elastomer grinding head 4 and the workpiece 5 are ground against each other, and the deterministic removal of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com