A kind of polyurethane micro flexible foam

A flexible foam and polyurethane technology, applied in the field of polyurethane, can solve the problems of large differences in performance between batches, difficult control of the reaction process, and many castor oil-based side groups, etc., and achieve an easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

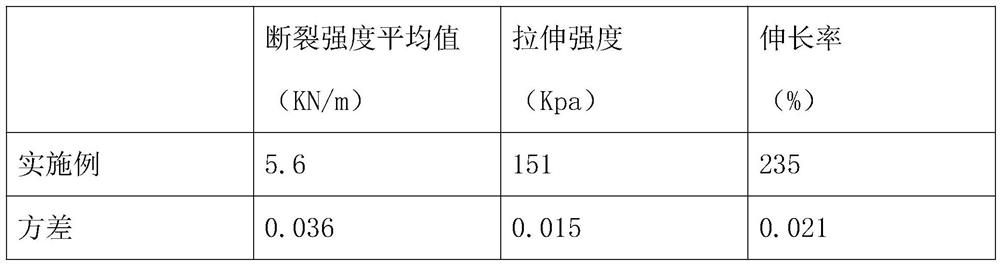

Examples

Embodiment

[0043] A polyurethane micro-flexible foam,

[0044] Including the following parts by weight:

[0045] Component A: 300 parts

[0046] Component B: 100 parts;

[0047] Described component A comprises factor weight part:

[0048] Polyether polyol: 30 parts

[0049] Polyester polyol: 50 parts

[0050] Cross-linking agent: 50 parts

[0051] Catalyst: 0.5 parts

[0052] Foaming agent: 5 parts;

[0053] The component B is isocyanate:

[0054] As a further improvement of the present invention,

[0055] The polyether polyol is

[0056] Copolymer of Propylene Oxide and Ethylene Oxide

[0057] 2-Butyne-1,4-diol diglyceride

[0058] panthenyl ethyl ether

[0059] mixture.

[0060] The polyether polyol is a copolymer of propylene oxide and ethylene oxide with a mass ratio of 10:1:1, 2-butyne-1,4-diol diglyceride, and panthenyl ethyl ether. mixture.

[0061] Described polyester polyol is:

[0062] Phthalic anhydride polyester polyol

[0063] 1,9-Heptadecen-4,6-diyne-3,8-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com