Heat-insulation cold-preservation insulation board for low-temperature storage tank and installation method thereof

A low-temperature storage tank and installation method technology, which is applied to the installation device of container structure, household packaging, fixed-capacity gas storage tank, etc., can solve the problems of poor structural strength and many parts, and achieve long service life, excellent heat preservation performance, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

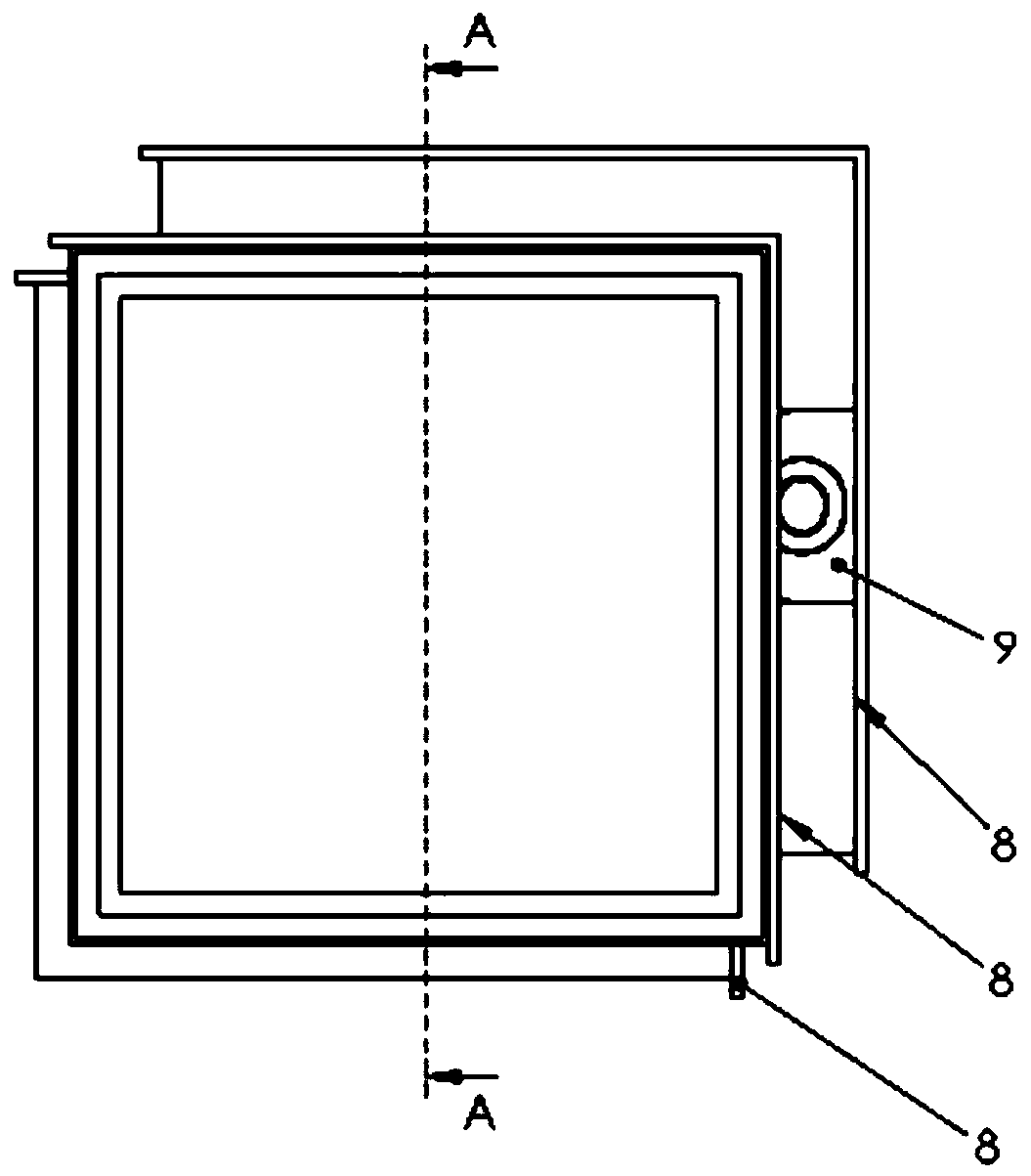

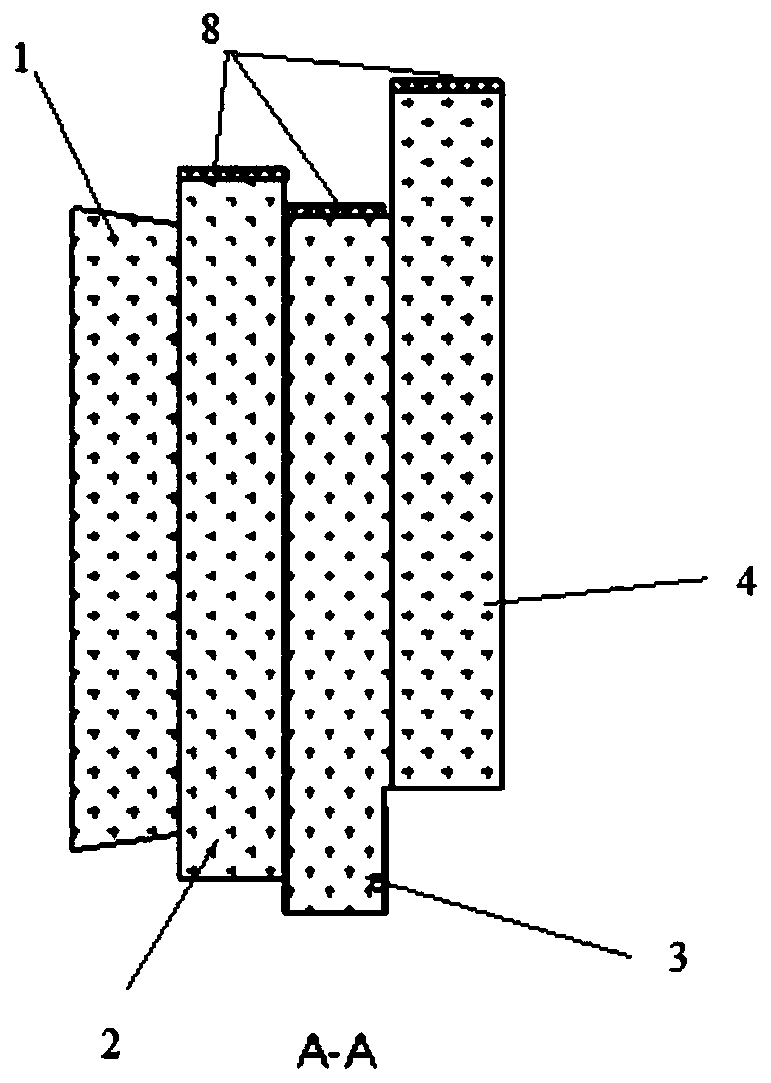

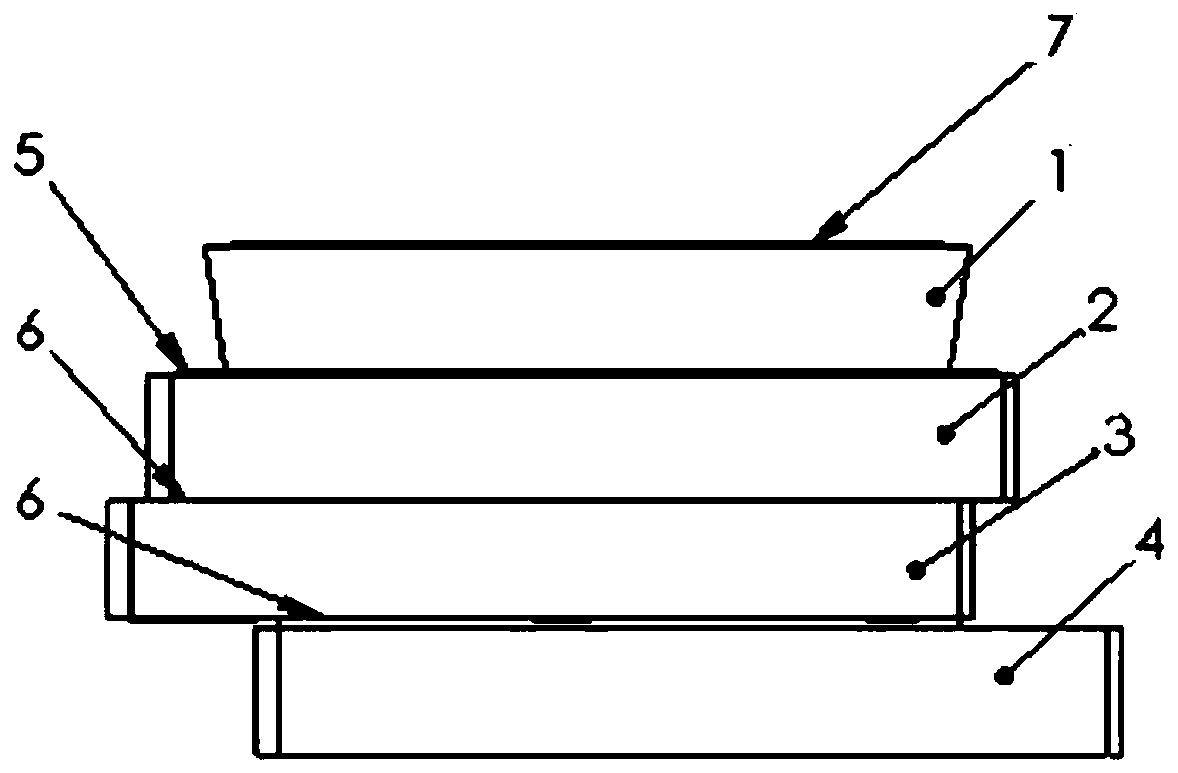

[0037] A heat-insulating and cold-preserving thermal insulation board for a low-temperature storage tank, the thermal insulation board comprises a high-temperature laminate 1, an upper middle laminate 2, a lower middle laminate 3, and a low-temperature laminate 4 arranged sequentially in layers, the high-temperature laminate 1 and the upper middle laminate A stainless steel mesh 5 is provided between the laminates 2, a mesh cloth 6 is provided between the upper intermediate laminate 2 and the lower intermediate laminate 3, and a gap for polyurethane filling is left between the lower intermediate laminate 3 and the low-temperature laminate 4 The outer surface of the high-temperature laminate 1 is provided with a protective skin 7, and the adjacent two sides of the upper middle laminate 2, the lower middle laminate 3 and the low-temperature laminate 4 are provided with elastic heat insulating materials 8.

[0038] The four sides of the high-temperature laminate 1 are butt joint s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com