Preparation method of porous film layer, electrochemical sensor and preparation method thereof

A sensor and electrochemical technology, applied in the field of electrochemical detection, can solve problems such as the reduction of mechanical and electrical properties of the porous film layer, the reduction of porosity and specific surface area, and the complex composition of the sol solution system, so as to achieve system ratio optimization, Effect of high porosity and improved detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

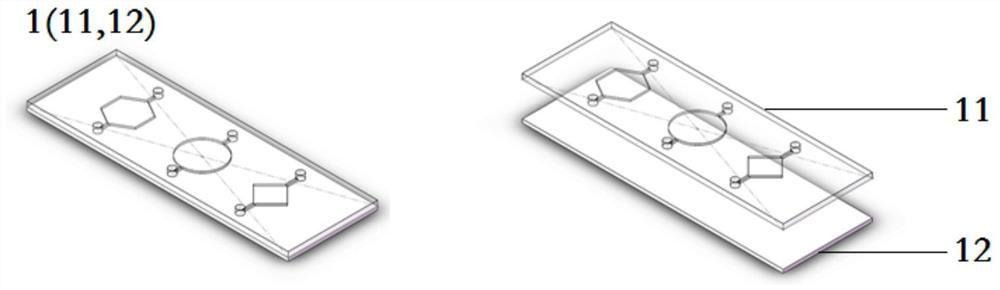

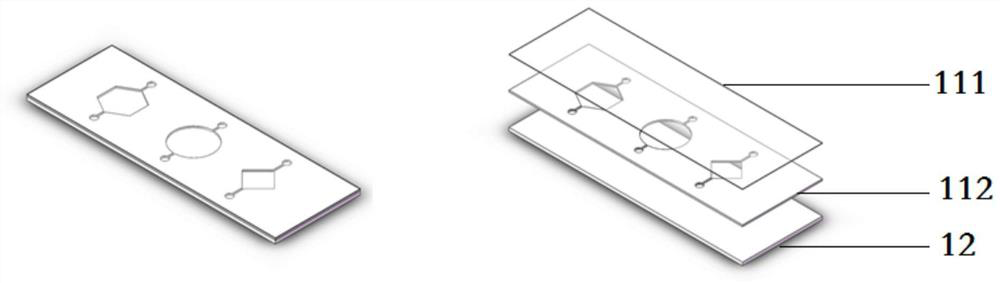

[0078] The present embodiment provides a kind of manufacturing mold 1 of porous film layer, as figure 1 As shown, a laminated preparation layer 11 and base layer 12 are included. The side of the preparation layer 11 facing the base layer 12 is recessed inward to form a pattern groove for preparing a porous film layer, and at least one sample inlet of the sol solution is provided on the side of the preparation layer 11 away from the base layer 12, and the inlet is connected. Graphic groove. The patterned grooves in the preparation layer 11 are prepared by methods such as micro-electro-mechanical machining (MEMS) or digitally controlled precision machining (CNC). After the preparation layer 11 is obtained, the contact surfaces of the preparation layer 11 and the base layer 12 are respectively surface treated, and then the preparation layer 11 is bonded on the base layer 12, and the pattern grooves in the preparation layer 11 are used as the preparation layer. The reaction cham...

Embodiment 2

[0081] This embodiment also provides a method for preparing a porous film layer. The porous film layer is prepared using the mold 1 of Example 1. The preparation method specifically includes the following steps:

[0082] (1) Get the aqueous solution (5mg / mL) of the graphene oxide of 1mL, add the vitamin C of 1mg wherein, after vitamin C fully dissolves, obtain graphene sol solution;

[0083] (2) The graphene sol solution is injected into the pattern groove through the injection port of the mold 1, and then the injection port is sealed to form an airtight reaction chamber; the mold 1 is placed in a water bath and kept at a temperature of 50°C 2h, obtain graphene porous gel;

[0084] (3) Open the sealed sample inlet to form an opening communicating with the outside world in the reaction chamber, and use deionized water to perform solvent replacement on the graphene porous gel for 6-9 times through the sample inlet to obtain a purified graphene porous gel. glue; after the graphe...

Embodiment 3

[0086] This embodiment provides a preparation method of a porous film layer, which differs from the preparation method provided in Example 2 in that:

[0087] In step (1), take 1mL of graphene oxide aqueous solution (10mg / mL), add 5mg of vitamin C to it, after vitamin C is fully dissolved, obtain graphene sol solution; In step (2), mold 1 is placed In a water bath, keep at a temperature of 70° C. for 0.5 h to obtain a graphene porous gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com