OLED device and preparation method thereof

A device and auxiliary cathode technology, which is applied in the field of OLED devices and its preparation, can solve problems such as voltage drop, and achieve the effect of improving voltage drop and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

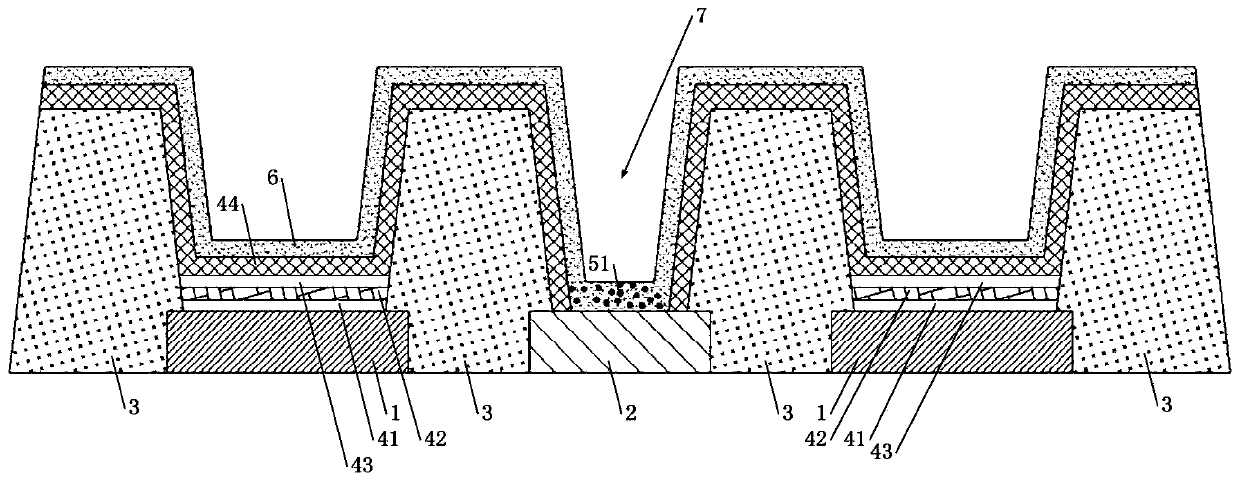

[0036] Such asfigure 1 As shown, the OLED device of this embodiment includes: a substrate (not shown in the figure), two anodes 1 , auxiliary cathodes 2 , two banks 3 , functional layers, thin film layers and surface cathodes 6 .

[0037] Wherein the two anodes 1 are arranged separately on the substrate, specifically, transparent electrodes made of transparent conductive films such as indium tin oxide (ITO) and indium zinc oxide (IZO) can be used, which have light transmission.

[0038] Wherein the auxiliary cathode 2 is arranged on the substrate between the two anodes 1, and the two dams 3 are relatively arranged above the two sides of the auxiliary cathode 2; the two dams 3 and the auxiliary cathode 2 A contact hole 7 is formed on the surface. Through the structure of the contact hole 7, the auxiliary cathode 2 and the surface cathode 6 are connected. Since the auxiliary cathode 2 has a small resistance, the voltage drop problem can be effectively solved by conducting the au...

Embodiment 2

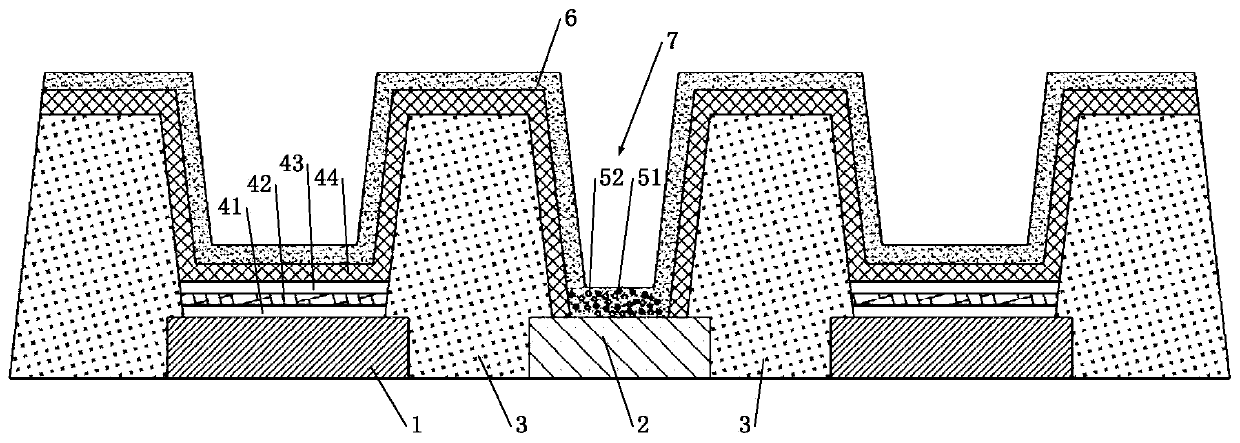

[0045] In the following, only the differences between the present embodiment and the first embodiment will be described, and the similarities will not be repeated here.

[0046] Such as figure 2 As shown, a conductive material 52 is also added in the thin film layer. Wherein the good conductor material is graphene and / or nano silver. The external conductor material 52 can enhance the conductivity of the thin film layer, thereby effectively solving the problem of voltage drop.

Embodiment 3

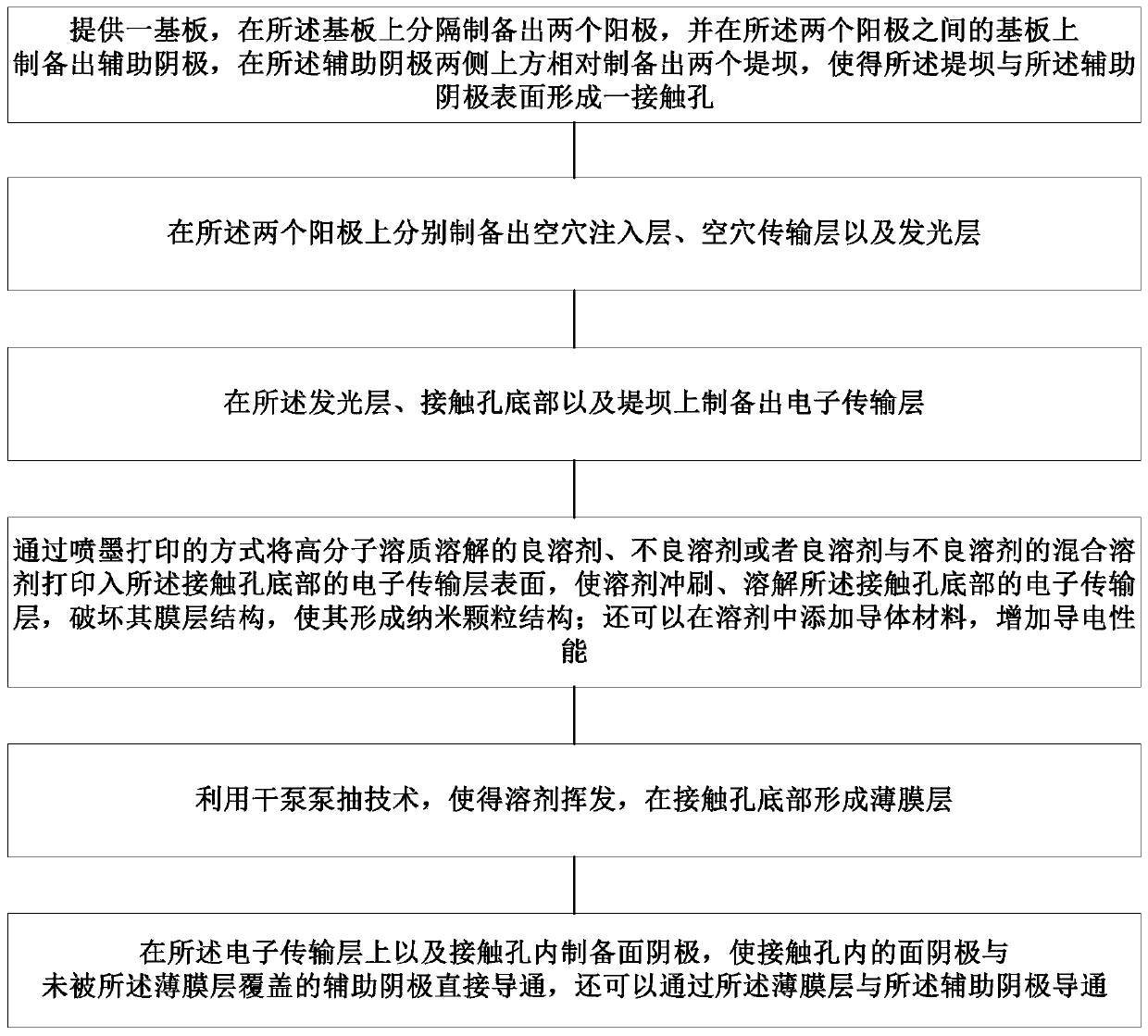

[0048] Such as image 3 As shown, this embodiment provides a method for preparing an OLED device. It includes: S1, providing a substrate, preparing two anodes 1 separately on the substrate, and preparing an auxiliary cathode 2 on the substrate between the two anodes 1, above the two sides of the auxiliary cathode 2 Two dams 3 are relatively prepared, so that a contact hole 7 is formed between the dam 3 and the surface of the auxiliary cathode 2; S2, a hole injection layer 41 and a hole transport layer are respectively prepared on the two anodes 1 42 and the luminescent layer 43; S3, the electron transport layer 44 is prepared on the luminescent layer 43, the bottom of the contact hole 7 and the dam 3; S4, a good solvent, a poor solvent or a good solvent for dissolving the polymer solute by inkjet printing A mixed solvent of a good solvent and a poor solvent is printed into the surface of the electron transport layer 44 at the bottom of the contact hole 7, so that the solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com