Reinforcing filler for high oil absorption resin

A super oil-absorbing resin and reinforced filler technology, applied in liquid separation, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor performance of secondary utilization, oil absorption and mechanical properties cannot reach the required level, etc. It can ensure the oil absorption performance, reduce the precipitation of reinforcing fillers, and improve the secondary oil absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

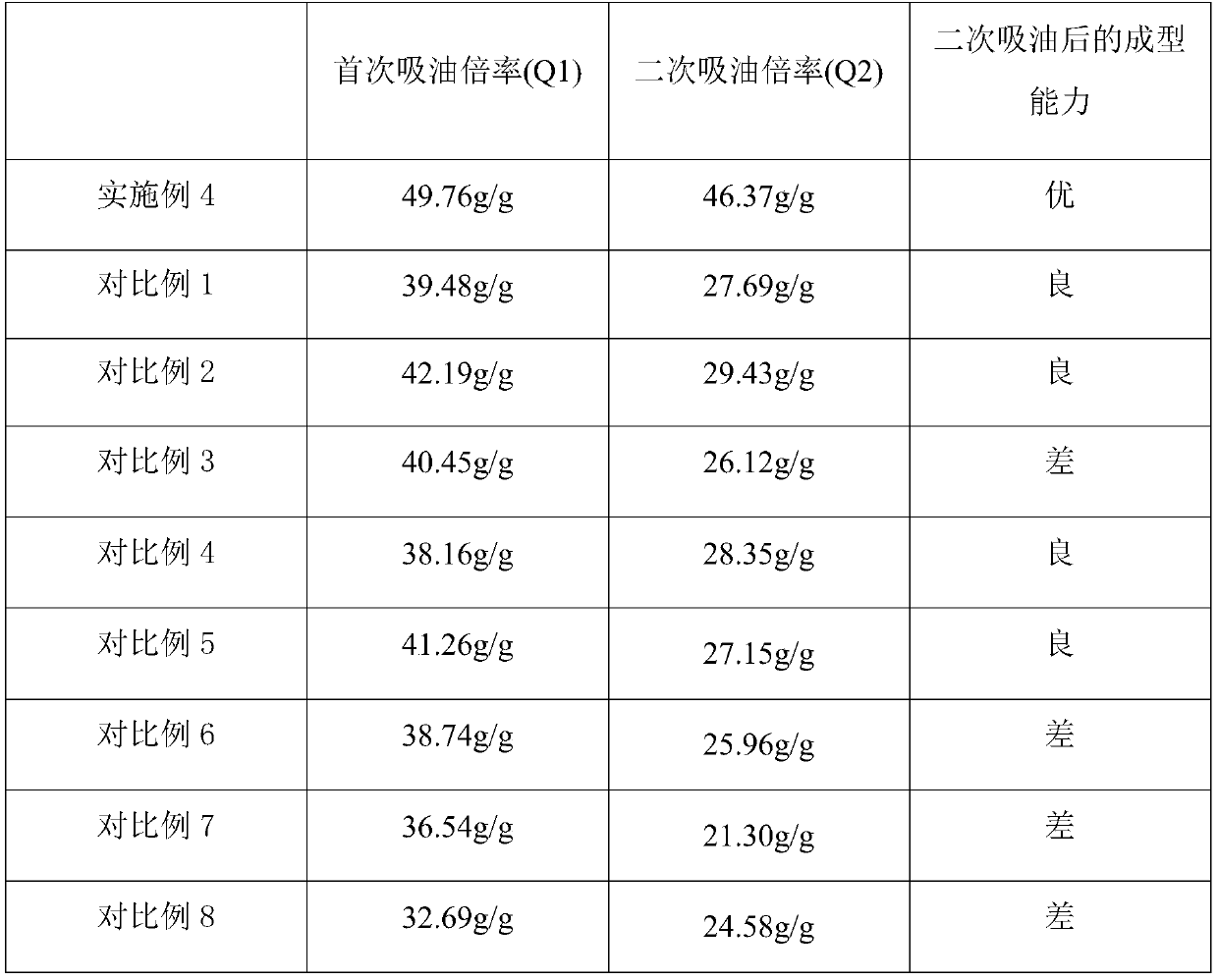

Examples

Embodiment 1

[0069] A reinforcing filler used in super oil-absorbing resins, in parts by weight, comprising the following components:

[0070] 50 parts of modified lignin powder;

[0071] 8 parts of glass fiber powder;

[0072] 5 parts of low molecular weight PVA;

[0073] 3 parts of silane coupling agent;

[0074] The preparation method of described reinforcing filler comprises the following steps:

[0075] (1) Preparation of modified lignin powder

[0076] A. Put the lignin powder in a beaker, and add a hydrochloric acid solution with a mass percentage concentration of 5 wt% in the beaker, stir the two and ultrasonically disperse them for 2 hours to obtain a suspension;

[0077] B. The suspension obtained in step A is centrifuged to obtain the lower sediment;

[0078] C, the lower precipitate in step B is washed with deionized water, and dried;

[0079] D. Grinding the dried precipitate in step C into powder to obtain the modified lignin powder;

[0080] (2) Preparation of reinfor...

Embodiment 2

[0084] A reinforcing filler used in super oil-absorbing resins, in parts by weight, comprising the following components:

[0085] 50 parts of modified lignin powder;

[0086] 15 parts of glass fiber powder;

[0087] 5 parts of low molecular weight PVA;

[0088] 3 parts of silane coupling agent;

[0089] The preparation method of described reinforcing filler comprises the following steps:

[0090] (1) Preparation of modified lignin powder

[0091] A. Put the lignin powder in a beaker, and add a hydrochloric acid solution with a mass percentage concentration of 5 wt% in the beaker, stir the two and ultrasonically disperse them for 2 hours to obtain a suspension;

[0092] B. The suspension obtained in step A is centrifuged to obtain the lower sediment;

[0093] C, the lower precipitate in step B is washed with deionized water, and dried;

[0094] D. Grinding the dried precipitate in step C into powder to obtain the modified lignin powder;

[0095] (2) Preparation of reinfo...

Embodiment 3

[0099] A reinforcing filler used in super oil-absorbing resins, in parts by weight, comprising the following components:

[0100] 50 parts of modified lignin powder;

[0101] 1 part glass fiber powder;

[0102] 5 parts of low molecular weight PVA;

[0103] 3 parts of silane coupling agent;

[0104] The preparation method of described reinforcing filler comprises the following steps:

[0105] (1) Preparation of modified lignin powder

[0106] A. Put the lignin powder in a beaker, and add a hydrochloric acid solution with a mass percentage concentration of 5 wt% in the beaker, stir the two and ultrasonically disperse them for 2 hours to obtain a suspension;

[0107] B. The suspension obtained in step A is centrifuged to obtain the lower sediment;

[0108] C, the lower precipitate in step B is washed with deionized water, and dried;

[0109] D. Grinding the dried precipitate in step C into powder to obtain the modified lignin powder;

[0110] (2) Preparation of reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com