Pollution-free environment-friendly casting molding sand and preparation method thereof

A casting type, non-polluting technology, applied in the direction of casting molding equipment, casting molds, cores, etc., can solve the problems of incompatibility with the new normal economy, faults of industrial technicians, and high degree of environmental pollution, so as to reduce the time of grinding and Cost reduction, elimination of sand holes in castings, smooth and delicate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

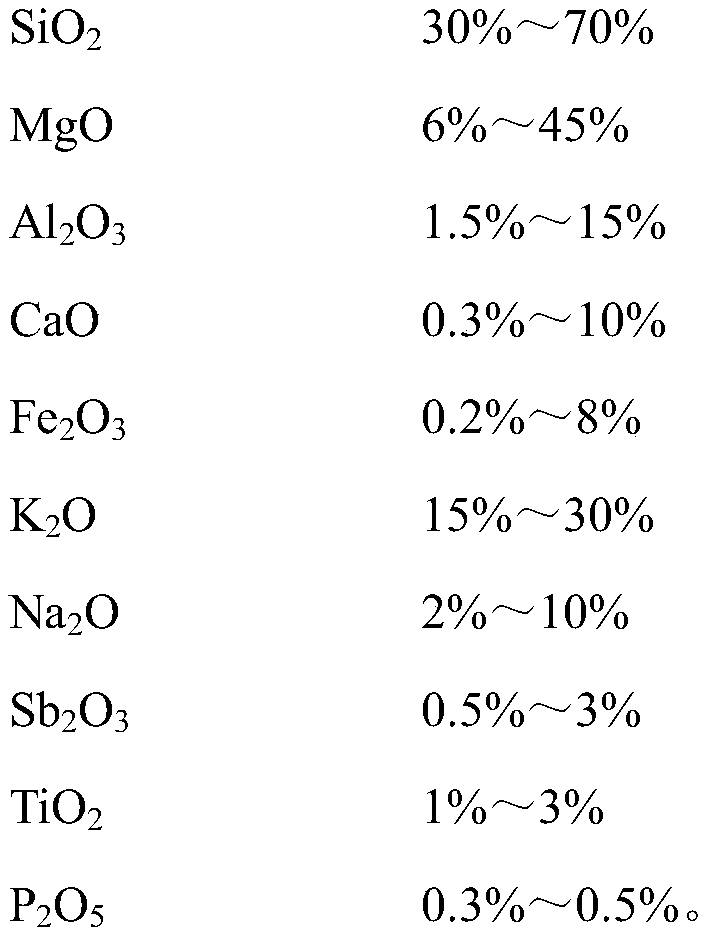

[0029] A more specific pollution-free and environmentally friendly foundry sand, including the following components by weight percentage:

[0030]

[0031] The raw materials in the above formula are mixed conventionally to obtain pollution-free and environmentally friendly foundry sand.

Embodiment 2

[0033] A more specific pollution-free and environmentally friendly foundry sand, including the following components by weight percentage:

[0034]

[0035]

[0036] The raw materials in the above formula are mixed conventionally to obtain pollution-free and environmentally friendly foundry sand.

Embodiment 3

[0038] A more specific pollution-free and environmentally friendly foundry sand, including the following components by weight percentage:

[0039]

[0040] The raw materials in the above formula are mixed conventionally to obtain pollution-free and environmentally friendly foundry sand.

[0041] The performance analysis of above-mentioned embodiment:

[0042] 1. Analysis of pollution in the production process

[0043] The pollution analysis that the environment-friendly foundry sand casting of embodiment 1~3 produces:

[0044] (1) Waste water - no production sewage in this project

[0045] (2) Exhaust gas - the product of this project replaces pulverized coal, does not burn, has no smoke, and produces no exhaust gas.

[0046] (3) Solid waste - There is no solid waste in this project, and the sandy soil is recycled after treatment without waste residue.

[0047] (4) Noise—there is only the sound of the mixer during the production process of this project, and the noise is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com