Wet water high anti-slip inkjet ceramic brick with sunken glaze effect and preparation method thereof

A ceramic tile and anti-slip technology, which is applied in the field of ceramic tile production and manufacturing, can solve the problems of monotonous decorative visual effect, difficult to clean, easy to hide dirt, etc., and achieve good decorative effect, bright color, and excellent pollution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

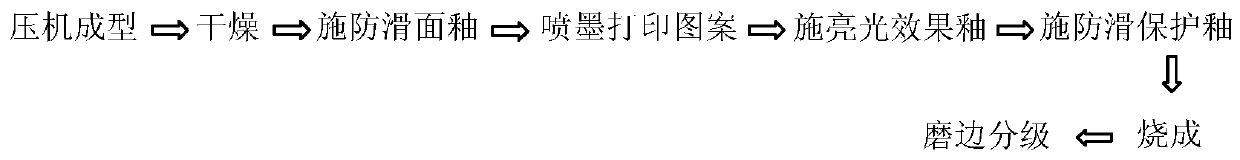

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0043] Step 2: Prepare anti-slip surface glaze according to the proportion: 50% potassium feldspar, 7% kaolin, 12% quartz, 11% calcined alumina, 5% nepheline, 7% zirconium silicate, 2% zinc oxide, 6% barium carbonate %. The chemical composition of the anti-skid glaze is: SiO 2 : 54.82%, Al 2 o 3 : 22.96%, Fe 2 o 3 : 0.2%, TiO 2 : 0.06%, CaO: 0.5%, MgO: 0.17%, K 2 O: 4.83%, Na 2 O: 2.74%, BaO: 4.65%, ZnO: 2%, ZrO 2 : 4.46%, loss on ignition: 2.83%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.84, and the amount of glaze is 420g / m 2 .

[0044] Step 3: Use an inkjet machine to inkjet print the pattern.

[0045] Step 4: prepare gloss effect glaze according to the ratio: albite 68%: calcined kaolin: 15%, wollastonite: 10%, calcined talc: 6%, calcined zinc oxide 1%. The...

Embodiment 2

[0052] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0053] Step 2: Prepare anti-slip surface glaze according to the ratio: 40% potassium feldspar, 10% albite feldspar, 10% kaolin, 8% quartz, 8% calcined alumina, 10% zirconium silicate, 10% barium carbonate, oxide Zinc 4%. The chemical composition of the anti-skid glaze is: SiO 2 : 51.40%, Al 2 o 3 : 19.60%, Fe 2 o 3 : 0.22%, TiO 2 : 0.06%, CaO: 0.25%, MgO: 0.17%, K 2 O: 3.84%, Na 2 O: 2.34%, BaO: 7.75%, ZnO: 3.99%, ZrO 2 : 6.37%, loss on ignition: 3.76%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.80, and the amount of glaze is 500g / m 2 .

[0054] Step 3: Use an inkjet machine to inkjet print the pattern.

[0055] Step 4: Prepare gloss effect glaze according to the ratio: albite 58%: calcined kaolin: 13%, wollastonite: 15%, calcined talc: 10%, calcined zinc oxide 3...

Embodiment 3

[0061] Step 1: Prepare the green body. The green body is obtained by pressing the ceramic base material commonly used in the field.

[0062] Step 2: Prepare anti-slip surface glaze according to the proportion: potassium feldspar 45%, albite 5%, kaolin 8.5%, quartz: 10%, calcined alumina 9.5%, nepheline: 2.5%, zinc oxide 3%, silicon Zirconium acid 8.5%, barium carbonate 8%. The chemical composition of the anti-skid glaze is: SiO 2 : 53.04%, Al 2 o 3 : 21.28%, Fe 2 o 3 : 0.22%, TiO 2 : 0.06%, CaO: 0.39%, MgO: 0.17%, K 2 O: 4.33%, Na 2 O: 2.54%, BaO: 6.20%, ZnO: 2.99%, ZrO 2 : 5.42%, loss on ignition: 3.36%. The non-slip surface glaze is poured on the dried brick adobe by glazing. The specific gravity of the glaze is 1.82, and the amount of glaze is 460g / m 2 .

[0063] Step 3: Use an inkjet machine to inkjet print the pattern.

[0064] Step 4: Prepare gloss effect glaze according to the ratio: albite 63%: calcined kaolin: 14%, wollastonite: 12.5%, calcined talc: 8%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com