A kind of preparation method of environment-friendly plastic runway

A plastic runway, environmentally friendly technology, applied in the direction of roads, roads, pavements, etc., can solve the problems of reducing the service life of the plastic runway, damage to the plastic runway, deformation of the plastic runway, etc., to achieve good high pressure resistance, improve service life, and avoid subsidence effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

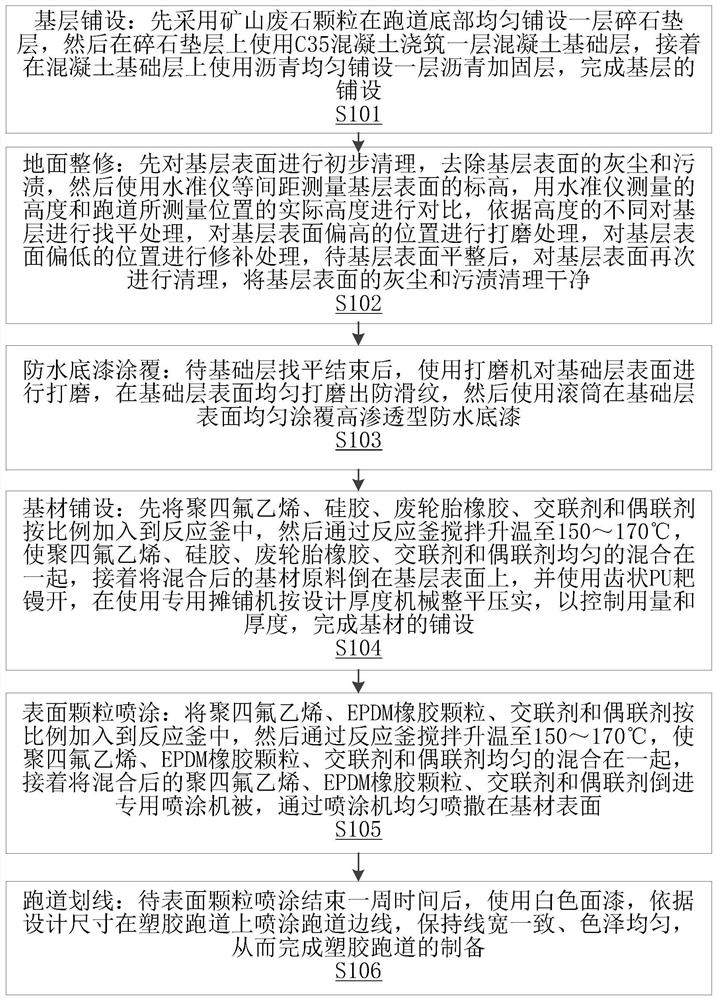

[0025] Example 1, see figure 1 , the present invention provides a technical solution: a method for preparing an environmentally friendly plastic runway, the method comprising:

[0026] S101: Base laying: First, a layer of gravel cushion is evenly laid on the bottom of the runway with mine waste rock particles, and then a concrete base layer is poured with C35 concrete on the gravel cushion, and then asphalt is evenly laid on the concrete base layer A layer of asphalt reinforcement to complete the laying of the base;

[0027] S102: Ground renovation: firstly clean the surface of the base, remove dust and stains on the surface of the base, then measure the elevation of the surface of the base at equal intervals with a level, compare the height measured by the level with the actual height of the position measured by the runway, and calculate the height according to the height According to the difference, level the base layer, polish the higher position of the base layer surface,...

Embodiment 2

[0043] Example 2, see figure 1 , the present invention provides a technical solution: a method for preparing an environmentally friendly plastic runway, the method comprising:

[0044] S101: Base laying: First, a layer of gravel cushion is evenly laid on the bottom of the runway with mine waste rock particles, and then a concrete base layer is poured with C35 concrete on the gravel cushion, and then asphalt is evenly laid on the concrete base layer A layer of asphalt reinforcement to complete the laying of the base;

[0045] S102: Ground renovation: firstly clean the surface of the base, remove dust and stains on the surface of the base, then measure the elevation of the surface of the base at equal intervals with a level, compare the height measured by the level with the actual height of the position measured by the runway, and calculate the height according to the height According to the difference, level the base layer, polish the higher position of the base layer surface,...

Embodiment 3

[0061] Example 3, see figure 1 , the present invention provides a technical solution: a method for preparing an environmentally friendly plastic runway, the method comprising:

[0062] S101: Base laying: First, a layer of gravel cushion is evenly laid on the bottom of the runway with mine waste rock particles, and then a concrete base layer is poured with C35 concrete on the gravel cushion, and then asphalt is evenly laid on the concrete base layer A layer of asphalt reinforcement to complete the laying of the base;

[0063] S102: Ground renovation: firstly clean the surface of the base, remove dust and stains on the surface of the base, then measure the elevation of the surface of the base at equal intervals with a level, compare the height measured by the level with the actual height of the position measured by the runway, and calculate the height according to the height According to the difference, level the base layer, polish the higher position of the base layer surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com