Fully mechanized mining face gettering-induction convection type dust control and removal wind fog screen device and method

A fully mechanized mining face and spray device technology, applied in safety devices, dust prevention, mining equipment, etc., can solve the threat to the health of workers in safe production operations, endanger the physical and mental health of workers in coal mining areas, mine safety production, control dust removal measures Dust reduction effect is not obvious and other problems, to achieve the effect of a safe production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

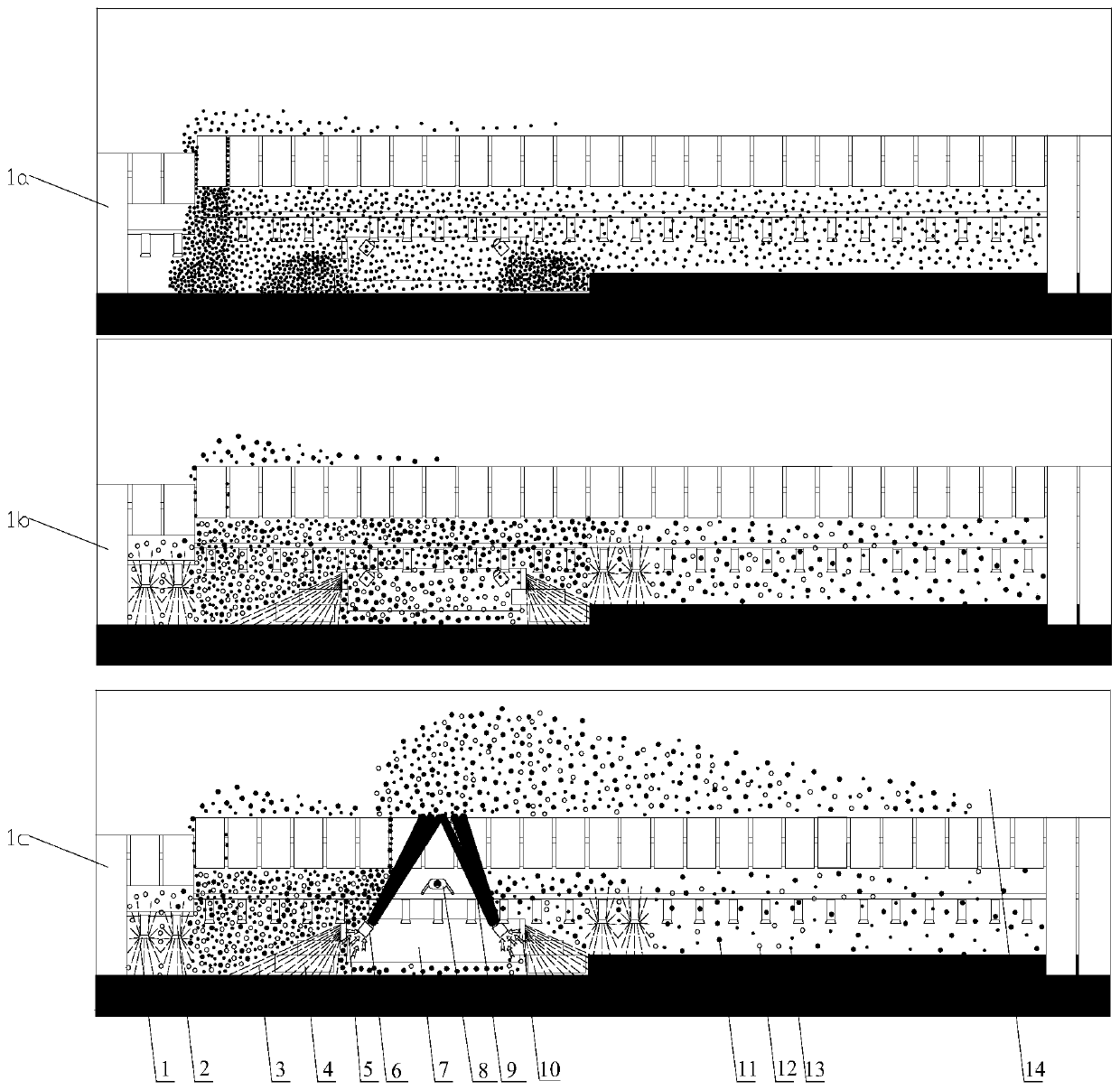

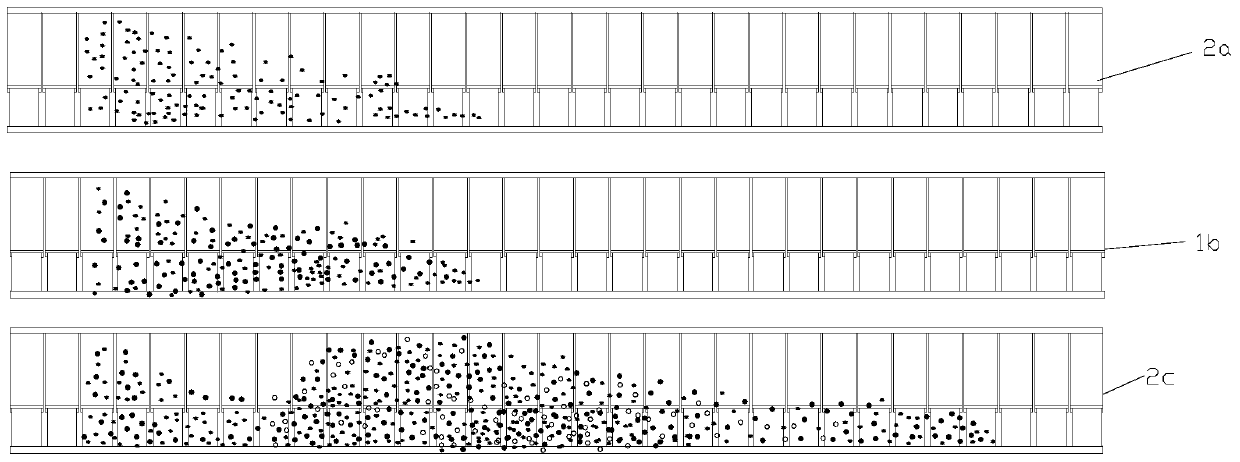

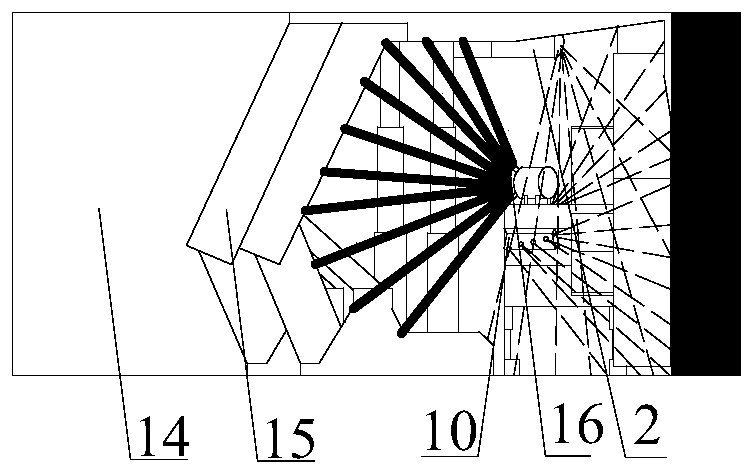

[0020] The present invention proposes a fully mechanized mining face suction-induced convection dust-removal wind and mist curtain device and method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0021] combine Figure 1 to Figure 3 As shown, a fully mechanized mining face suction-induced convection control dust removal wind and mist curtain device of the present invention includes a hydraulic support spray device 2, a drum 4, a draw-out dust cleaning fan 6, a shearer 7, and an outer shearer Spray device 10, hydraulic support 15 and fan-shaped shroud 16. The method mainly includes dust suction 5 purification, convective air curtain 9 dust resistance, inducing dust particles 13 to enter the gob 14 and spray dust reduction. Effective control of dust production in the two processes of coal cutting and rack moving.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com