Composition for on-line silicon meter detection, preparation method thereof and on-line silicon meter detection method

A detection method and composition technology, which are applied in the preparation of test samples, chemical method analysis, measurement devices, etc., can solve the problems of affecting the normal operation of silicon meters, high cost, and large consumption, so as to ensure normal operation, The effect of high accuracy and high solution cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

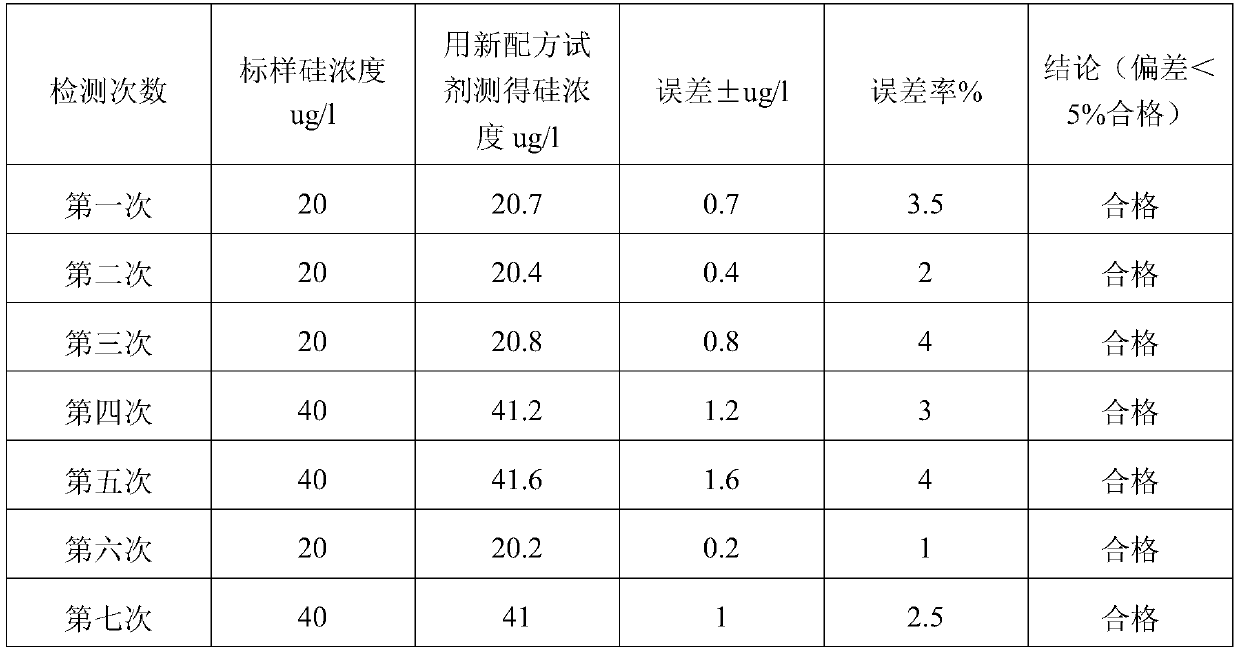

Examples

preparation example Construction

[0023] According to another aspect, the present invention also provides a method for preparing the above-mentioned composition for on-line silicon meter detection, which includes the following steps: S1, add a part of water into a marked container according to the proportion, and use a dropper to pour concentrated sulfuric acid Add it dropwise into water; then cool the container to room temperature, then add ammonium molybdate, stir until dissolved, add another part of water to obtain an acidic ammonium molybdate solution, that is, the color developer; Add a part of water to the container, add oxalic acid under constant stirring, and then add another part of water until it dissolves to obtain an oxalic acid solution, that is, a masking agent; Add ferrous ammonium sulfate under the state until it dissolves, place the container in a cold water bath, add concentrated sulfuric acid to the water dropwise with a dropper, and after cooling to room temperature, add another part of wate...

Embodiment 1

[0029] This embodiment has prepared the on-line silicon meter detection composition, specifically as follows: Chromogenic agent acidic ammonium molybdate: add about 1500 milliliters of desalted water in the marked container, carefully add 90 milliliters of vitriol oil (H 2 SO 4 The content is 98%, the density is 1.84g / cm 3 ), and then put the container into a water bath to cool to room temperature, add 100 grams of ammonium molybdate, fully stir until completely dissolved, and finally settle to 2 liters with desalted water. Equivalent to acidic ammonium molybdate solution including ammonium molybdate with a concentration of 50g / L, 81.14g / L of H 2 SO 4 and the remainder of water.

[0030] Masking agent oxalic acid: Add about 1200 ml of demineralized water into a marked container, add 80 grams of oxalic acid with constant stirring until it is completely dissolved, then add demineralized water to dilute to 2 liters. The equivalent oxalic acid solution includes oxalic acid wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com