Crane fatigue analysis system and method

A fatigue analysis and crane technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that crane fatigue failure analysis and safety assessment cannot be promoted in industrial applications, crane metal structure fatigue damage, and load spectrum does not exist universally Sexuality and other issues, to avoid production rhythm, save manpower, and facilitate implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

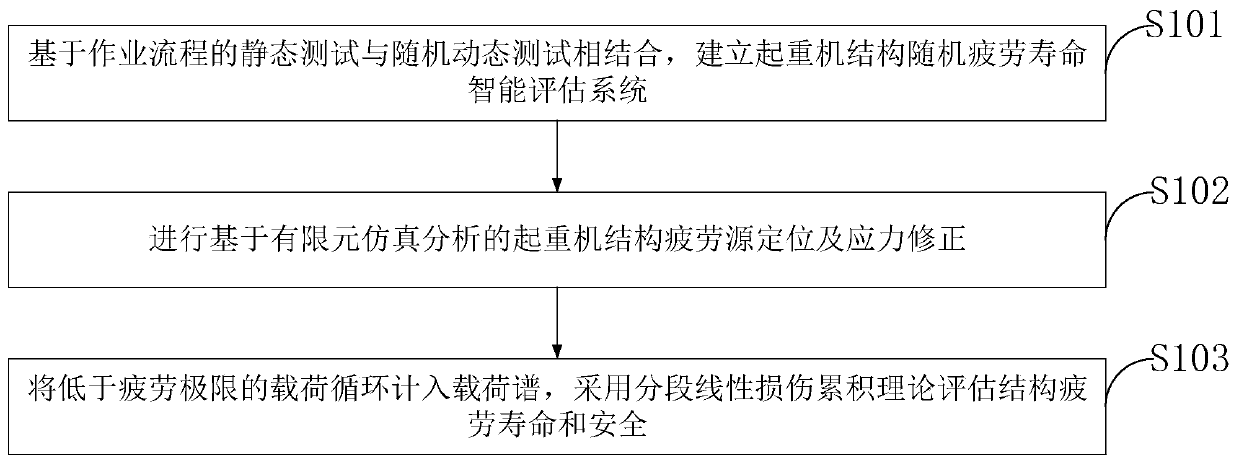

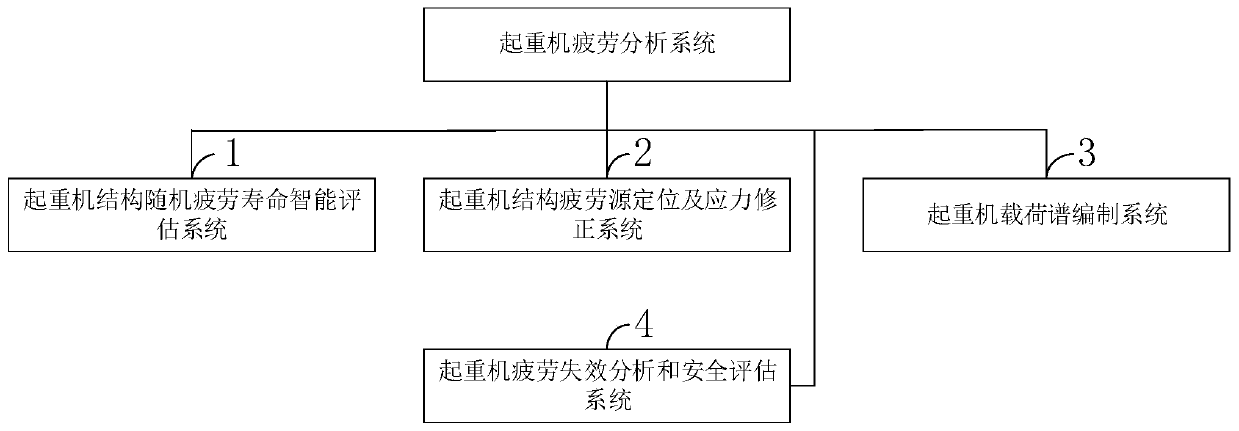

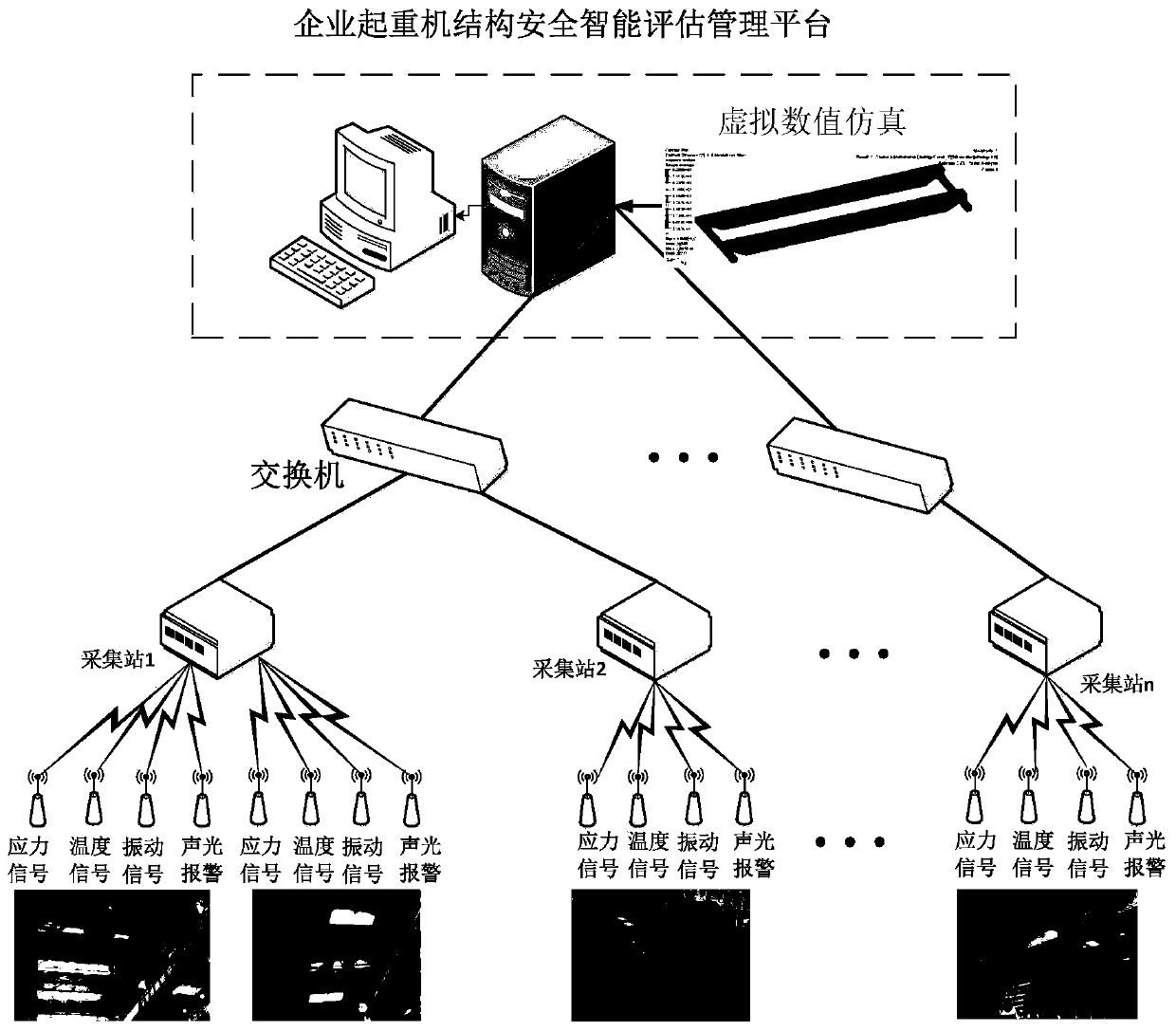

Method used

Image

Examples

Embodiment Construction

[0088] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0089] The stress intensity factor of structural cracks is an important parameter. For different crane parts and structures, and different crack forms, such as straight cracks, oblique cracks, penetration cracks or surface cracks, there is no similar analysis and literature. All the stress intensity factors are expressed as a function of the shape factor, and the value of the shape factor is generally 1.1-1.5. Obviously, this is not reasonable, because the shape factor changes with the change of the crack length, and the change of the crack length is related to the load. The size, history, crane structure and crack locatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com