Turning tool changing method based on part surface roughness and power information

A technology of surface roughness and power information, used in computer parts, metal processing equipment, metal processing machinery parts, etc., can solve problems such as multi-energy, prone to errors, increased tool cost, etc., and achieve comprehensive and accurate identification of information. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The present invention will be further described below in conjunction with the content of the present invention and the embodiments described in the accompanying drawings.

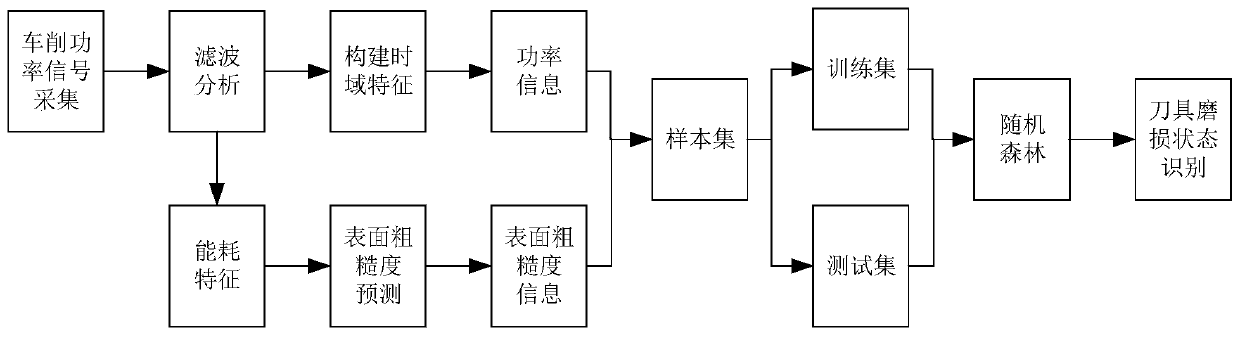

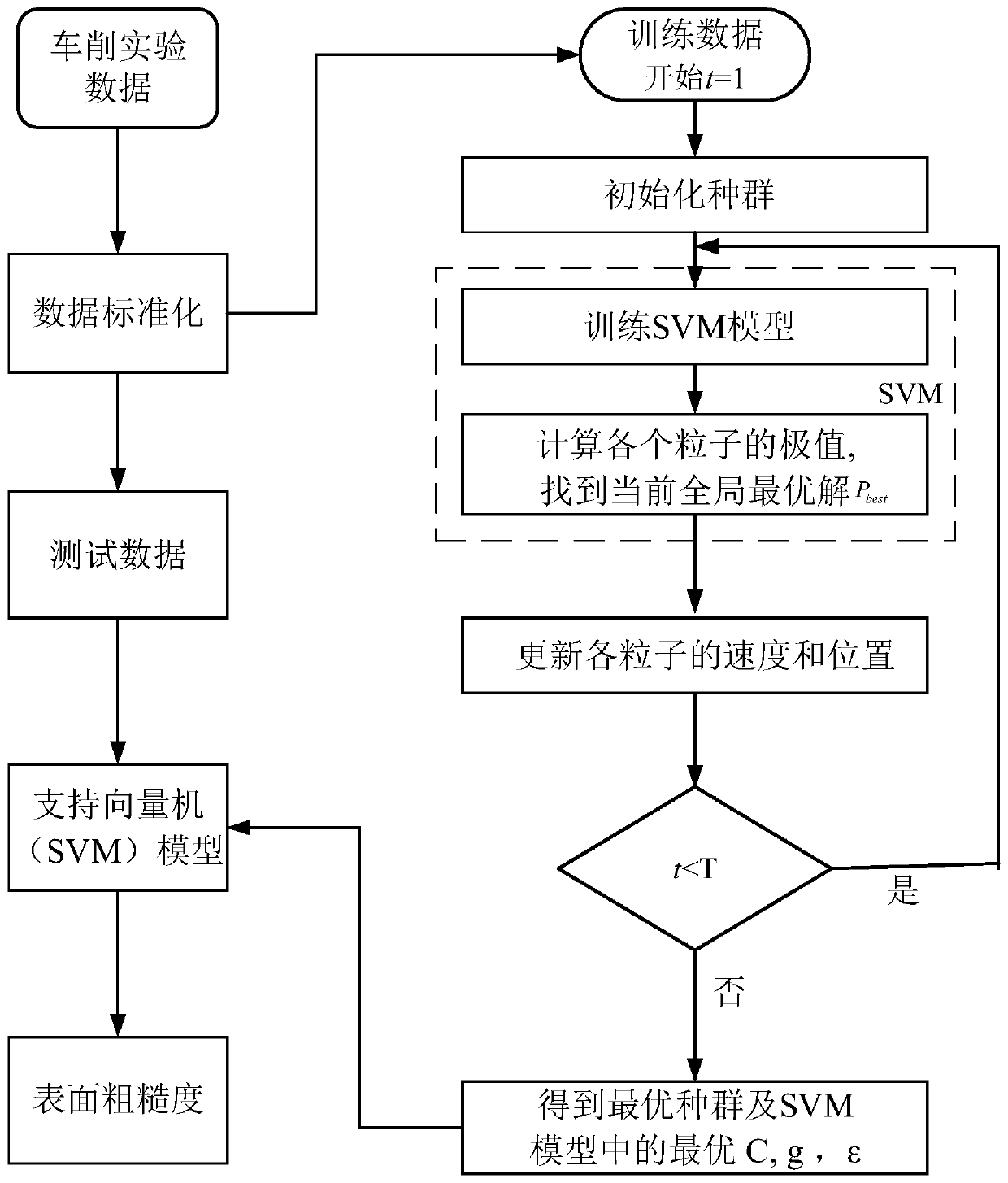

[0069] The present invention proposes a tool changing method for turning machining based on the surface roughness and power information of the part, such as figure 1 shown, including the following steps:

[0070] Step 1, signal acquisition and analysis.

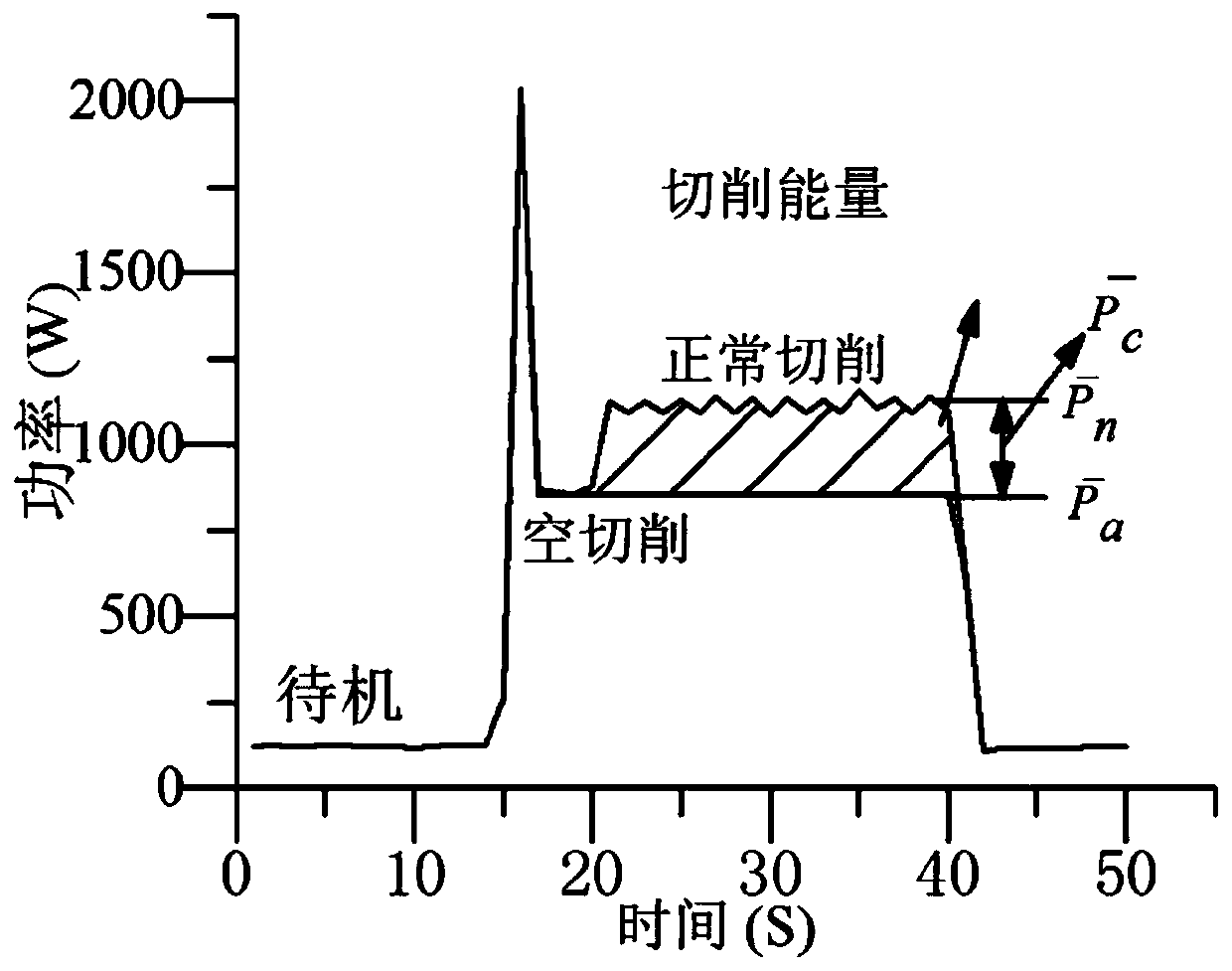

[0071] Signal acquisition and analysis include the collection of power signals and processing parameter information, which refers to the power signal measured by the power sensor in the whole process of processing, including machine tool start-stop, processing and other states, reading the three cutting elements (spindle speed, depth of cut, feed rate) values. Noise and interference exist in the power signal. In order to eliminate the influence of processing waiting time, the power signal from the beginning to the end of cutting of the machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com