Device for increasing concentration multiple of membrane and concentration of concentrated solution and use method

A membrane concentration, high-concentration technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficulty in interception rate, influence of feed properties, accelerated membrane fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

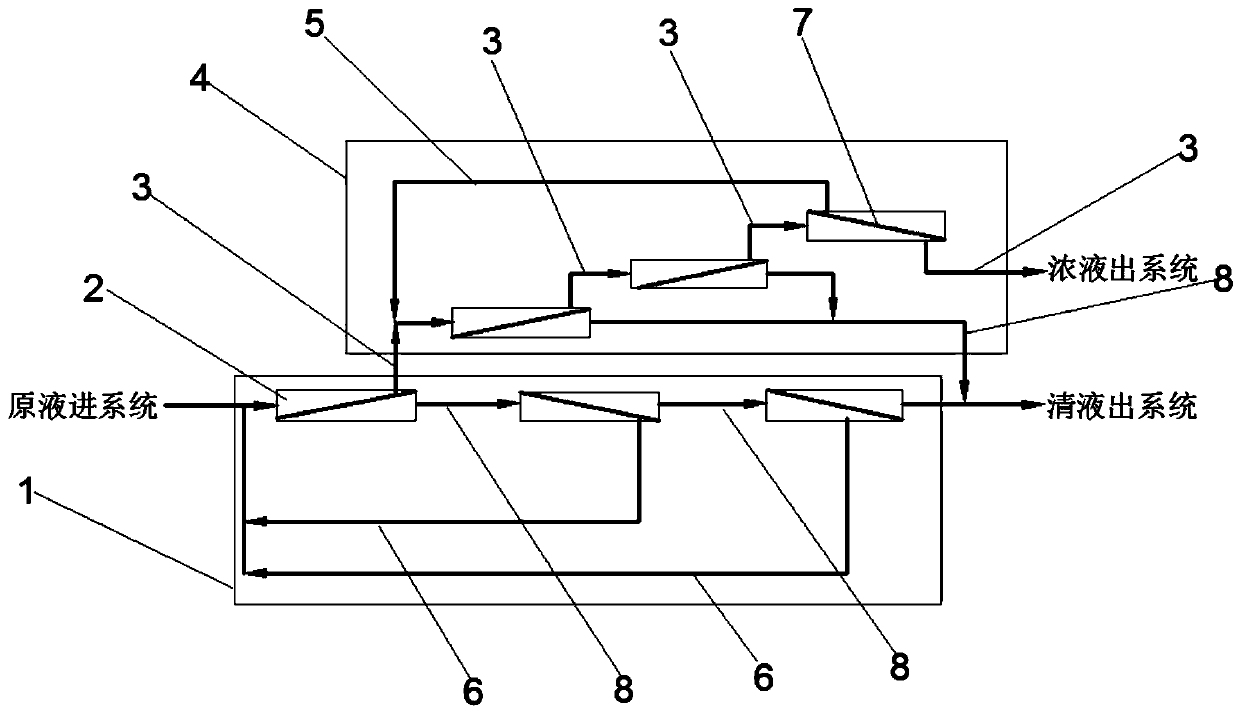

[0040] refer to Figure 1-6 , the magnesium sulfate solution that needs to be processed is passed into the concentrated liquid series independent concentration section through the raw liquid inlet system, and the concentrated liquid that enters the concentrated liquid series section 4 is separated into concentrated liquid and clear liquid step by step again, and the concentrated liquid at the terminal The liquid is discharged from the concentrated liquid outlet pipe, and the terminal clear liquid is returned from the clear liquid return pipe 5 to the filter tank 2 of the first stage in the multi-stage filter tank, and the clear liquid on the filter tank 2 of each stage is discharged through the clear liquid tube discharge.

[0041] The composition of magnesium sulfate solution before process treatment is as follows:

[0042] Table 1

[0043]

[0044] Table 2

[0045]

[0046] table 3

[0047]

[0048] Table 4

[0049]

[0050] In Table 1-4, "<" plus detection ...

Embodiment 2

[0067] refer to Figure 1-6, the black wolfberry dried fruit extract that needs to be processed is passed into the clear liquid series section 1 to separate the black wolfberry dried fruit extract into concentrated liquid and clear liquid step by step, and the clear liquid at the terminal is discharged from the clear liquid outlet pipe, and the filter tanks at all levels The dope on 2 returns to the original liquid inlet system through the dope return pipe 6.

[0068] The components of black wolfberry dried fruit extract before processing are shown in Table 7:

[0069] Table 7

[0070]

[0071] The traditional open circulation or intermittent semi-open and semi-closed system does not come out after the raw liquid enters the system, which cannot meet the needs of concentration of high-concentration raw liquid at all.

[0072] The test data of the concentrated solution after the process treatment device of the present application is processed is shown in Table 8:

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com