Double-doped calcium aluminate type near-infrared reflective pigment and preparation method thereof

A reflective pigment, near-infrared technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., to achieve the effects of short reaction cycle, easy control of the reaction process, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides double-doped CaAl described in the above technical scheme 2 o 4 The preparation method of type near-infrared reflective pigment comprises the following steps:

[0029] (1) Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , Fe(NO 3 ) 3 Mix with water, citric acid, and ethylene glycol to obtain a mixed solution;

[0030] (2) heating the mixed solution to obtain a sol;

[0031] (3) The sol is dried and calcined in sequence to obtain the double-doped CaAl 2 o 4 type near-infrared reflective pigments.

[0032] The present invention will Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , Fe(NO 3 ) 3 Mix with water, citric acid, and ethylene glycol to obtain a mixed solution. In the present invention, the Ca(NO 3 ) 2 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 and Fe(NO 3 ) 3 The molar ratio is preferably 28.3:5.0:(55.0-61.7):(5.0-11.7), more preferably 28.3:5.0:(58.0-60.0):(8.0-10.0). In the present invention, the Ca(NO 3 ) 2 Preferably Ca(NO 3 )...

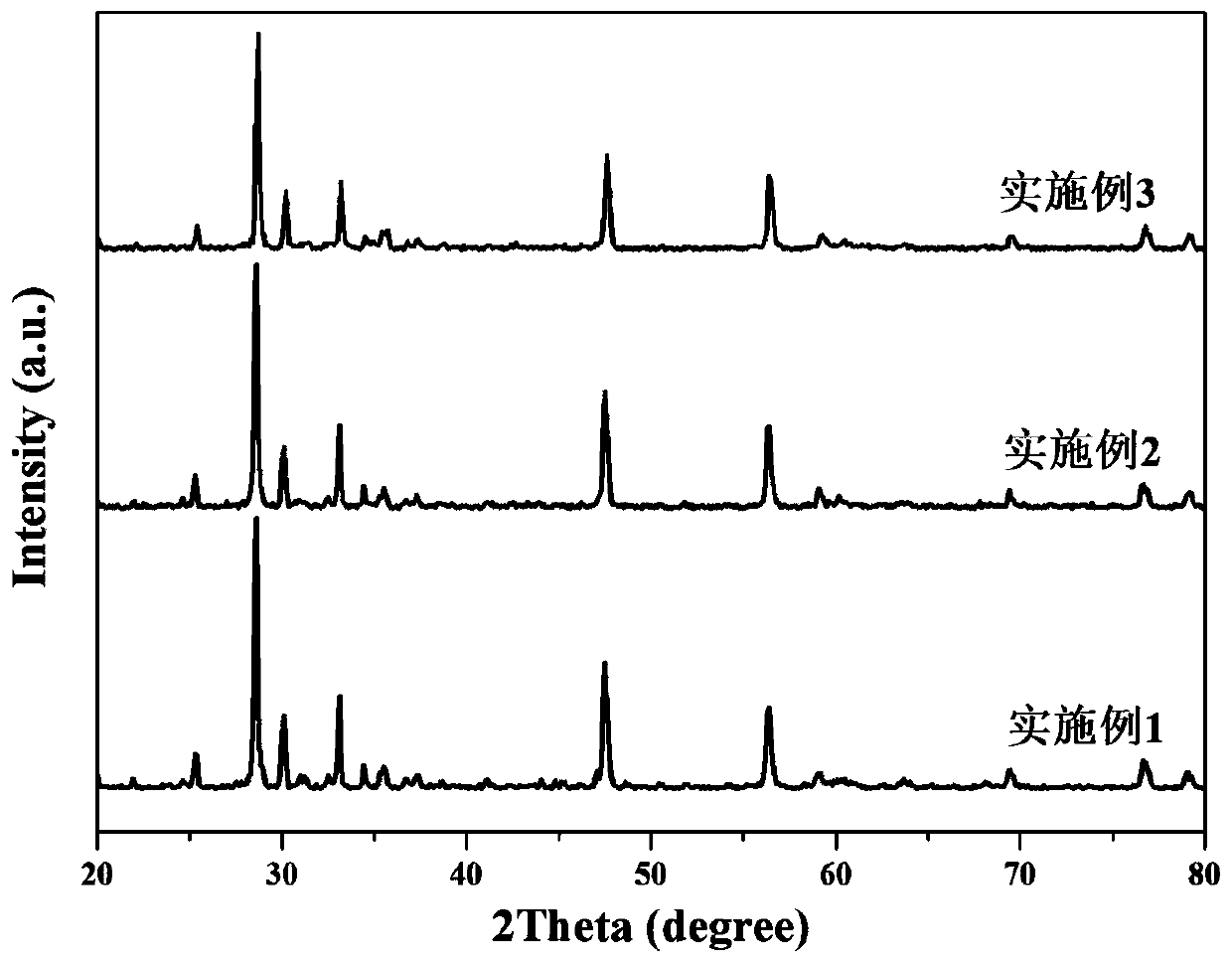

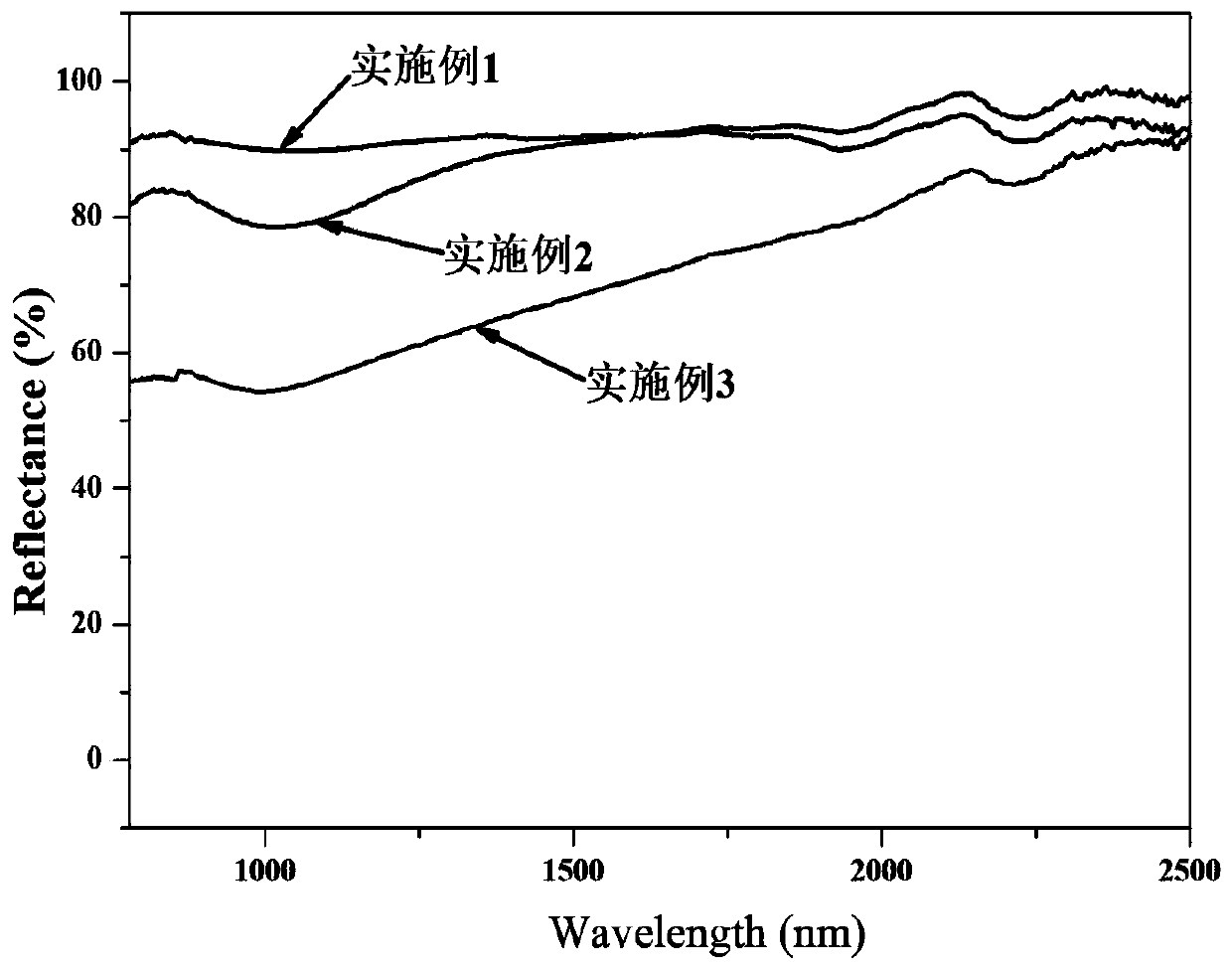

Embodiment 1

[0040] Prepare according to the mole percentage of metal elements: Ca(NO 3 ) 2 4H 2 O is 28.3%, Ce(NO 3 ) 3 ·6H 2 O is 5%, Al(NO 3 ) 3 9H 2 O is 61.7%, Fe(NO 3 ) 3 9H 2 O is 5% mixed with water, the mass ratio of water and metal nitrate is 5:1, stirred until completely dissolved to obtain a mixed solution; then citric acid and ethylene glycol are added to the mixed solution, citric acid and the above metal The molar ratio of ions is 3:1, the molar ratio of ethylene glycol and citric acid is 2:3, stir until completely dissolved; then put the mixed solution into a water bath for water bath heating, the heating temperature is 60°C, and the heating time is 4h , to obtain a sol; then put the sol into an oven for drying at a drying temperature of 120° C. and a drying time of 12 hours to obtain a xerogel. Then grind the obtained xerogel and put it into a muffle furnace for calcination. Under the atmosphere of air, start to heat up from room temperature at a rate of 5°C / min...

Embodiment 2

[0042] Prepare according to the mole percentage of metal elements: Ca(NO 3 ) 2 4H 2 O is 28.3%, Ce(NO 3 ) 3 ·6H 2 O is 5%, Al(NO 3 ) 3 9H 2 O is 58.4%, Fe(NO 3 ) 3 9H 2O is 8.3% mixed with water, the mass ratio of water to metal nitrate is 6:1, stirred until completely dissolved to obtain a mixed solution; then citric acid and ethylene glycol are added to the mixed solution, citric acid and the above metal The molar ratio of ions is 3:1, the molar ratio of ethylene glycol and citric acid is 2:3, stir until completely dissolved; then put the mixed solution into a water bath for water bath heating, the heating temperature is 80°C, and the heating time is 2h , to obtain a sol; then put the sol into an oven for drying at a drying temperature of 110° C. and a drying time of 14 hours to obtain a xerogel. Then grind the obtained xerogel and put it into a muffle furnace for calcination. Under the atmosphere of air, start to heat up from room temperature at a rate of 5°C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com