Biomass microwave catalytic pyrolysis method for catalyst regeneration and integrated device thereof

A microwave catalysis and catalyst technology, which is used in indirect heating dry distillation, preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc., can solve problems such as low reaction efficiency, and achieve the effects of improving utilization efficiency, slowing down deactivation rate, and improving reaction thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

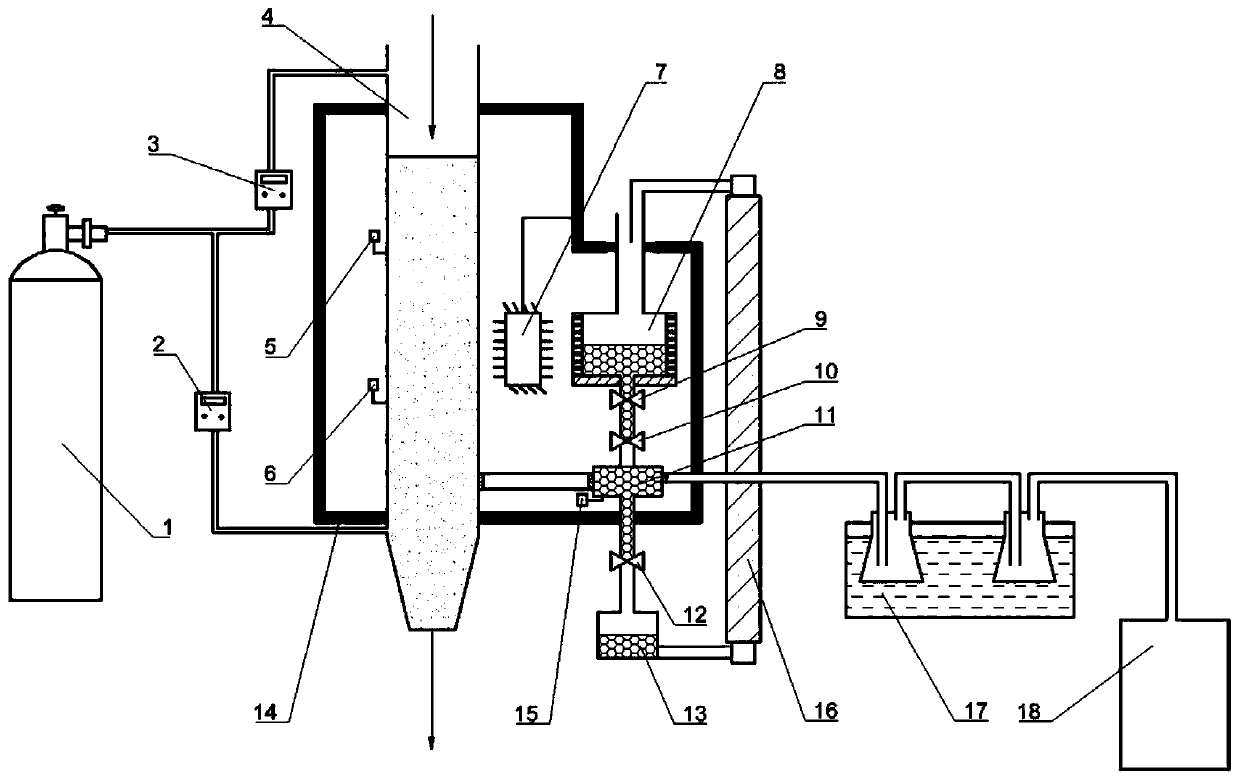

[0033] This embodiment provides a biomass microwave catalytic pyrolysis integrated device for catalyst regeneration. The integrated device includes a gas device 1, a vertical quartz tube 4, a microwave heating device 7, a catalyst regeneration zone 8, and a catalytic reforming zone. 11. Deactivated catalyst collection area 13, screw feeder 16, condensation area; the gas device 1 is connected to the side wall of the vertical quartz tube 4, and the inert gas is passed into the vertical quartz tube 4, and placed in the vertical quartz tube 4 There is biomass, and the inert gas provides an oxygen-free environment and carrier gas for the biomass; the vertical quartz tube 4 is successively a feed area, a pyrolysis area, a tar removal area and a discharge area from top to bottom, and the feed There is an inlet on the top of the area, and an outlet at the bottom of the discharge area. Biomass is added from the inlet. The biomass is pyrolyzed in the pyrolysis zone to produce pyrolysis g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com