Deep frost prevention system under condition that air-cooling module machine water circulation unit is broken down

An air-cooled module and antifreeze system technology, which is applied in the direction of reversible cycle compressors, refrigerators, refrigeration components, etc., can solve the problem that the unit cannot be antifreeze, and achieve the effect of preventing frost cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

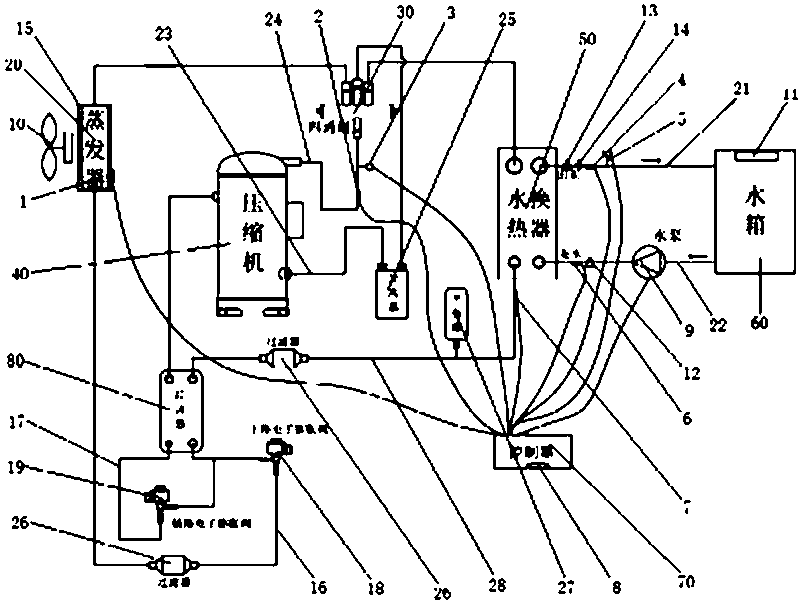

[0024] Such as figure 1 The shown deep antifreeze system under the fault condition of a water circulation unit of an air-cooled modular machine includes a fan 10, an evaporator 20, a four-way valve 30, a compressor 40, a water heat exchanger 50, a water tank 60 and a controller 70. A water outlet pipe 21 is connected between the water outlet end of the water heat exchanger 50 and the water inlet end of the water tank 60, and a water inlet pipe 22 is connected between the water inlet end of the water heat exchanger 50 and the water outlet end of the water tank 60. A water flow switch 5 is provided on the water pipe 21, and a water pump 9 is provided on the water inlet pipe 22, and the water pump 9 is electrically connected to the controller 70; the fan 10 is arranged on one side of the evaporator 20; An air intake pipe 23 and an exhaust pipe 24 are respectively provided, the other ends of the air intake pipe 23 and the exhaust pipe 24 are all connected to the four-way valve 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com