A kind of liquid sensor and its preparation method and application

A liquid sensor, organic solvent technology, applied in the direction of material resistance, etc., can solve the problem of inability to detect liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method of preparing a liquid sensor according to the above technical scheme, comprising the steps of:

[0038] Laser irradiation is carried out on both sides of polyimide paper to obtain graphene paper;

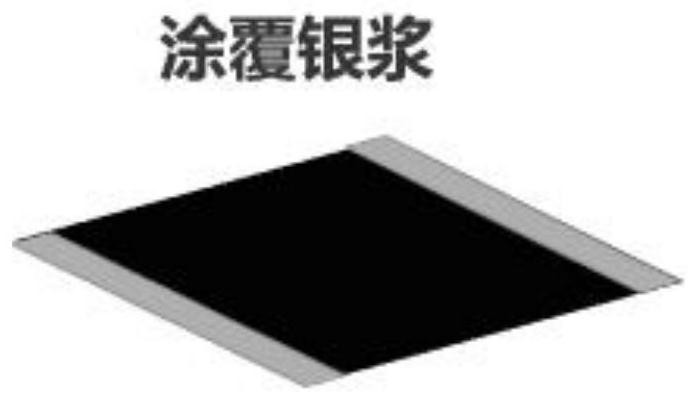

[0039] A silver paste is applied to both ends of the graphinyl paper, and the silver coating is formed, and the liquid sensor is obtained.

[0040] The present invention performs laser irradiation to both sides of the polyimide paper to obtain graphe paper. In the present invention, the polyimide (PI) paper is a commercially available product well known to those skilled in the art, and the polyimide paper is preferably 10 cm × 10 cm.

[0041] In the present invention, the laser light is preferably a carbon dioxide laser, preferably 9.3 to 12 μm, more preferably 9.5 to 11.5 μm; the irradiation method is preferably a filling scan mode; the image density of the laser irradiation is preferably from 100 to 1000 ppi, More preferably, 200 to ...

Embodiment 1

[0052] Polyimide (PI) paper is purchased in the commercial market. Equipped with a wavelength of 10.6μm CO 2 The laser laser irradiation system (DLS 2.3, Universal Laser Systems, INC) is illuminated by filling scan mode, and the laser irradiation parameter is: the image density is fixed to 500ppi, the scan rate is 7inch / s, and the area of the PI paper is 10 × 10 cm. 2 Single-sided scan time is 8 minutes, single sheet 100cm 2 The total LIGP has a total time of 16 min, the scanning power is 10W, and the parameters of the two sides are the same.

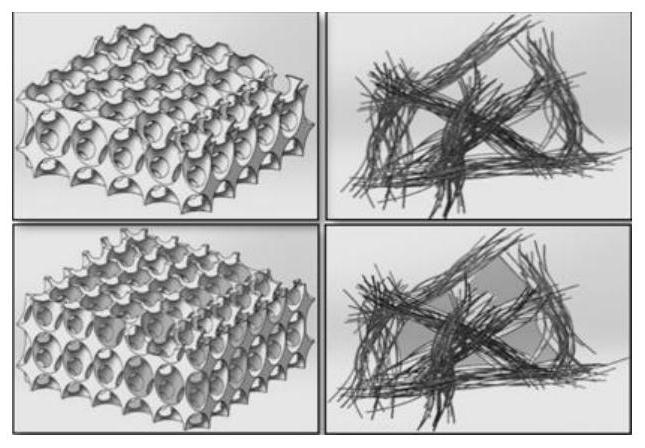

[0053] The resulting graphe paper was cut into a sample of 1 cm × 1 cm, and the silver slurry layer was coated between the two pairs, forming a silver coating having a width of 0.1 mm, length of 1 cm, resulting in figure 1 The liquid sensor shown. Add the organic solvent to the graphe paper, adopted figure 2 Expressive diagram showing the infiltration: figure 2 The above figure shows the structural schematic structural view of the gr...

Embodiment 2~5

[0055] The graphe paper was prepared according to the first embodiment, and the power difference was different, and the power of Example 2 was 11 W, and the power of Example 3 was 12 W, Example 4 is 13 W, and Example 5 is 15W.

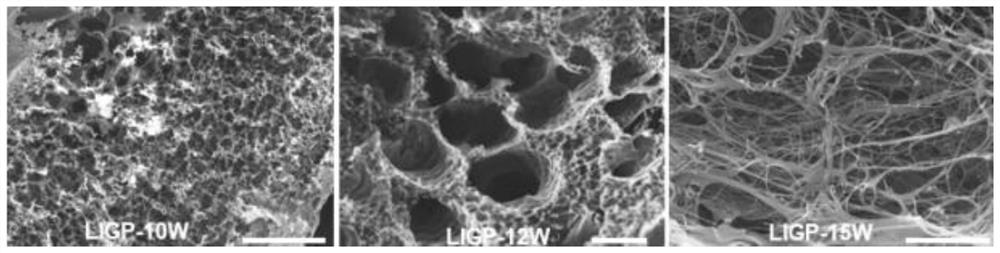

[0056] The graphe paper obtained in Example 1, Example 3 and Example 5 was used as an example, and the resulting graphene paper line SEM was characterized to study the change of the microstructure of the graphite paper obtained at different power, characterized image 3 Indicated. image 3 The SEM map of the graphe paper obtained by the left to right is shown in Example 1, Example 3 and Example 5, respectively, by the figure, as the power increases, the microstructure of graphene paper from more small hole structures Gradually transition to the middle hole, then transform to the large pore structure consisting of the fibrous shape, which directly affects the specific surface area of the stone insert.

[0057] The specific surface area of the Si-MP mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com