Preparation method of iridium catalyst

A catalyst and compound technology, applied in the field of preparation of [IrCl]2, can solve the problems of long reaction time, low product purity, and large amount of raw materials, and achieve the effects of short reaction time, high yield and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

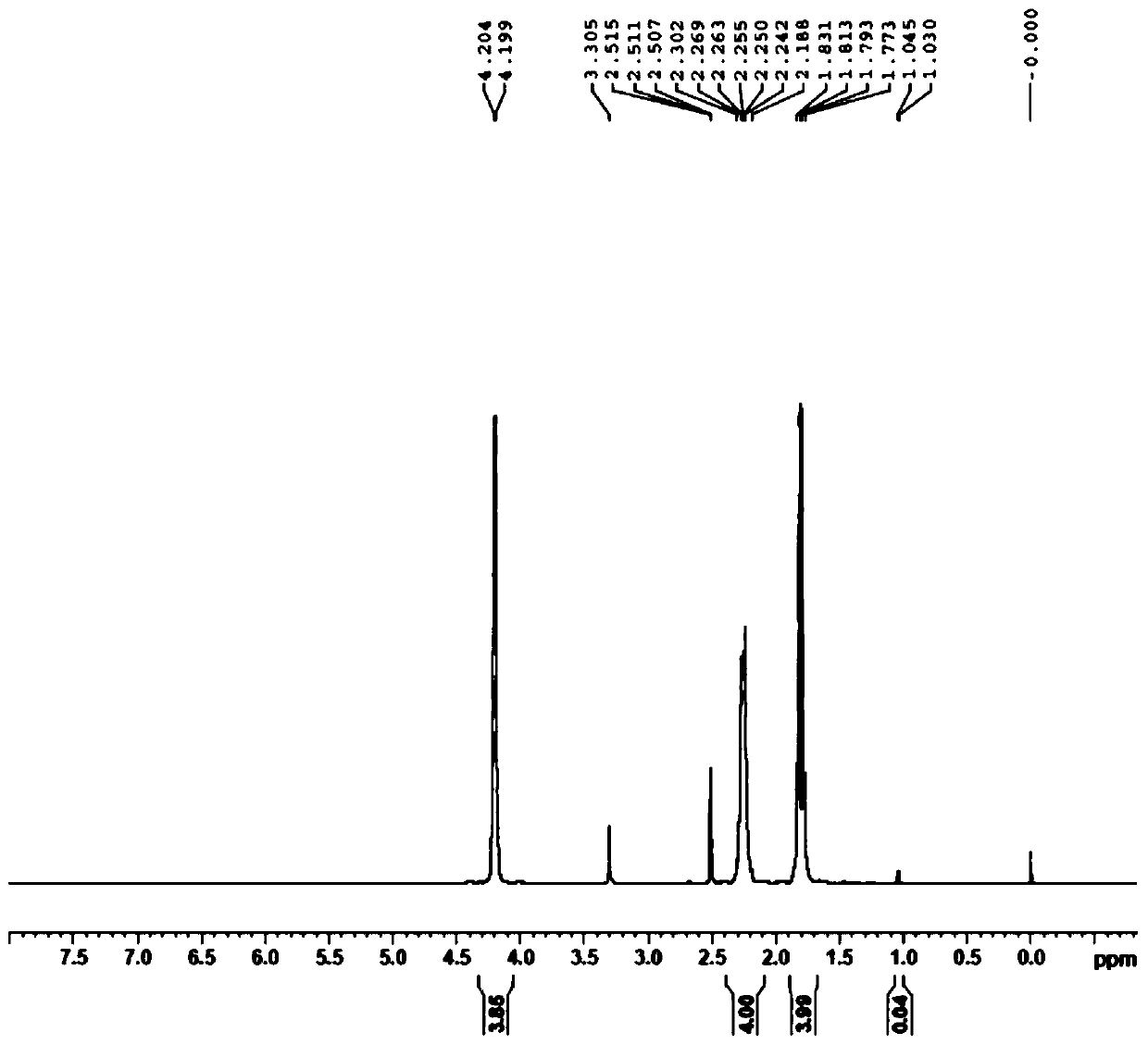

[0027] Dissolve iridium chloride in anaerobic water to obtain a solution with 10% iridium content, add cyclooctadiene with a molar ratio of 2 times, add hydrazine hydrate dropwise under anaerobic conditions and vigorous stirring, the reaction temperature is 90 °C, and add dropwise to no Precipitation is generated, filtered, and the filter cake is washed with anaerobic water, evaporated and crystallized to obtain cyclooctadiene iridium chloride [IrCl(C 8 h 12 )] 2 . After the filtrate was separated, the cyclooctadiene was continued to be used. Yield 99.5%, mass purity 99%, iridium content: 56.71%, elemental analysis carbon content: 28.35%, nuclear magnetic H-NMR see attached figure 2 .

Embodiment 2

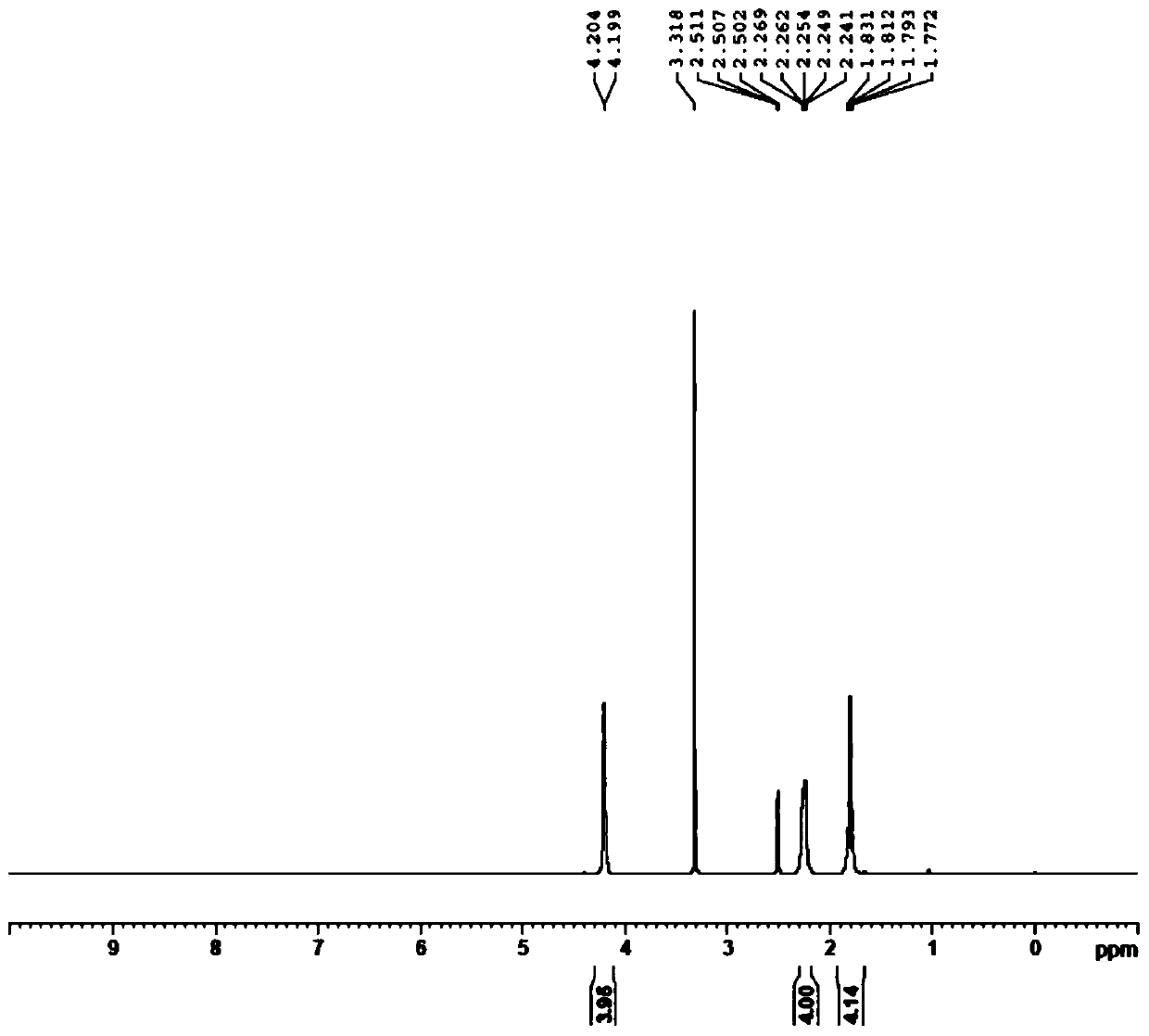

[0029] Dissolve chloroiridic acid in anaerobic water to obtain a solution with 10% iridium content, add cyclooctadiene with a molar ratio of 2 times, add sodium borohydride dropwise under anaerobic conditions and vigorous stirring, the reaction temperature is 80 ° C, dropwise to No precipitation is generated, filter, wash the filter cake with anaerobic water, evaporate and crystallize to obtain cyclooctadiene iridium chloride [IrCl(C 8 h 12 )] 2 . After the filtrate was separated, the cyclooctadiene was continued to be used. Yield 99.5%, mass purity 99%, iridium content: 56.77%, elemental analysis carbon content: 28.38%, nuclear magnetic H-NMR see attached image 3 .

Embodiment 3

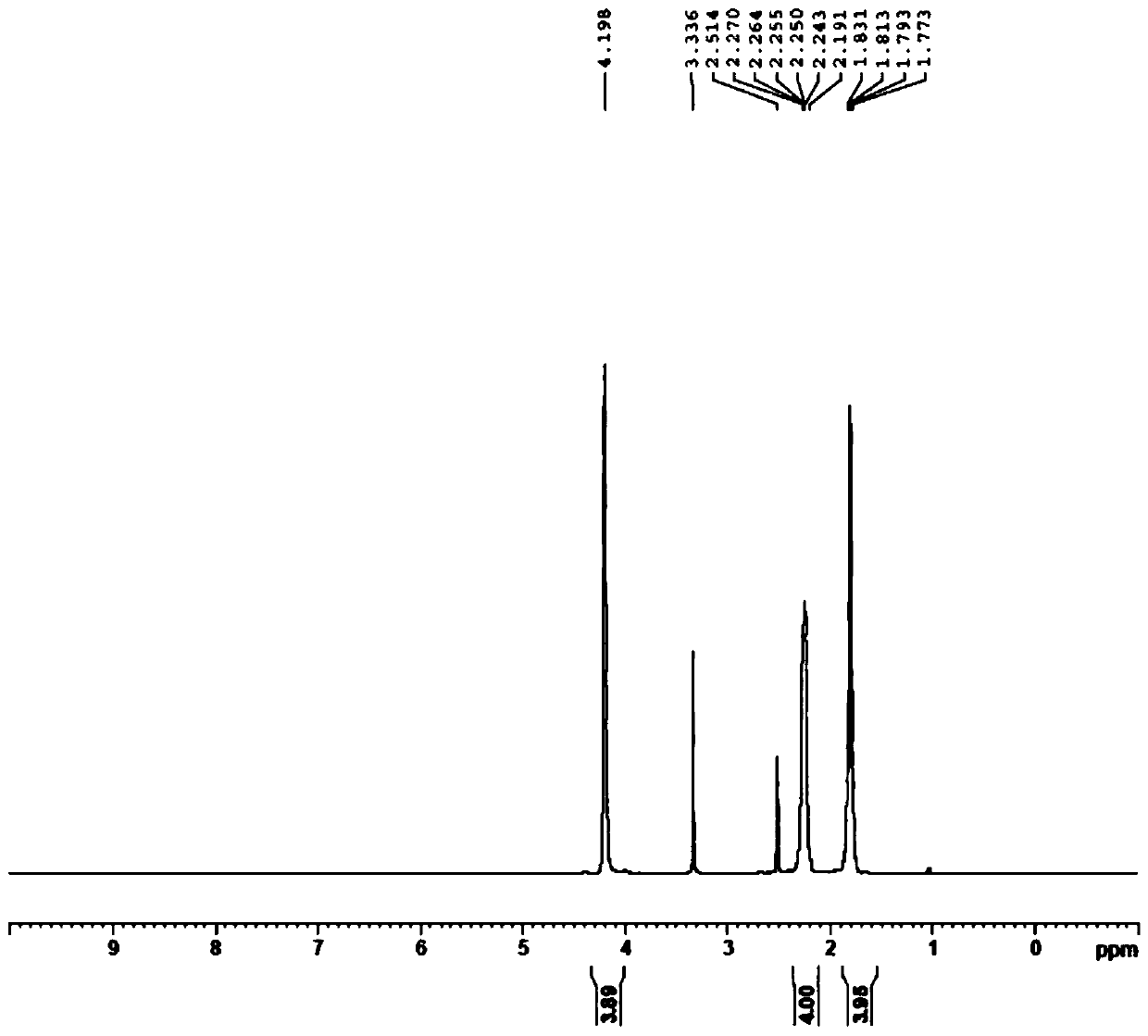

[0031] Dissolve sodium chloroiridate in anaerobic water to obtain a solution with 10% iridium content, add cyclooctadiene with a molar ratio of 2 times, add hydrazine hydrate dropwise under anaerobic conditions and vigorous stirring, the reaction temperature is 90 °C, and add dropwise to No precipitation is generated, filter, wash the filter cake with anaerobic water, evaporate and crystallize to obtain cyclooctadiene iridium chloride [IrCl(C 8 h 12 )] 2 . After the filtrate was separated, the cyclooctadiene was continued to be used. Yield 99.5%, mass purity 99%, iridium content: 56.66%, elemental analysis carbon content: 28.32%, nuclear magnetic H-NMR see attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com