Cardanol/epoxy acrylate composite resin for three-dimensional laser printing and preparation method

An epoxy acrylate and laser three-dimensional technology, applied in the direction of additive processing, etc., can solve the problem that the curing time cannot be shortened, and achieve the effect of reducing application cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

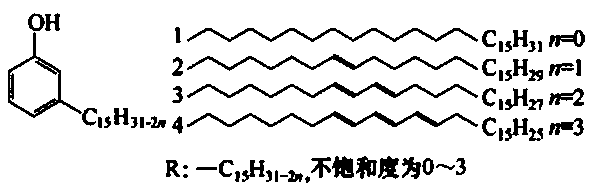

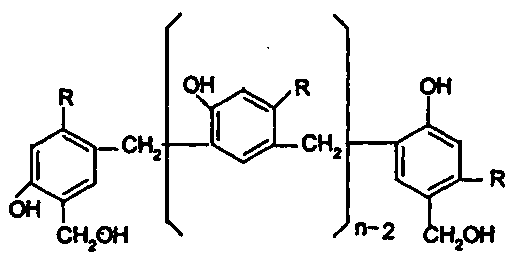

Method used

Image

Examples

Embodiment 1

[0021] Mix cardanol resin and bisphenol A epoxy acrylate at a mass ratio of 100:10, and add 1% of the total mass of the two photoinitiators 2,4-diethylthiazolone and stir evenly to obtain a laser three-dimensional printing Cardanol / epoxy acrylate composite resin; the resin is coated on tinplate (thickness 100μm), under 400nm ultraviolet light (100μW / cm 2 ) under irradiation, the resin can be cross-linked and cured within 40s, the cross-linking degree is 82.5%, and the bending performance of the resin film reaches 8mm without cracks. Print the splines with a 3D printer, and the molding shrinkage of the splines is 0.5%.

Embodiment 2

[0023] Mix cardanol formal and bisphenol A epoxy acrylate at a mass ratio of 100:20, and add 1% of the total mass of the two photoinitiators 2-isopropylthioxanthone and stir evenly to obtain laser three-dimensional printing Cardanol / epoxy acrylate composite resin was used; the resin was coated on tinplate (thickness 100μm), under 400nm ultraviolet light (100μW / cm 2 ) under irradiation, the resin can be cross-linked and cured within 35s, the cross-linking degree is 80.1%, and the bending performance of the resin film reaches 8mm without cracks. Print the splines with a 3D printer, and the molding shrinkage of the splines is 0.5%.

Embodiment 3

[0025] Mix cardanol resin and bisphenol A epoxy acrylate at a mass ratio of 100:40, and add 1% of the total mass of the two photoinitiators 2-isopropylthioxanthone and stir evenly to obtain a laser three-dimensional printing Cardanol / epoxy acrylate composite resin; the resin is coated on tinplate (thickness 100μm), under 400nm ultraviolet light (100μW / cm 2 ) under irradiation, the resin can be cross-linked and cured within 30s, the cross-linking degree is 81.9%, and the bending performance of the resin film reaches 8mm without cracks. Printed into splines with a 3D printer, the molding shrinkage of the splines is 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com