Bulletproof steel plate and manufacturing method thereof

A manufacturing method and technology for steel plates, applied in the field of steelmaking, can solve the problems of poor formability and welding performance, high price and high strength, and achieve the effects of good shape control, reduced smelting cost and low alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

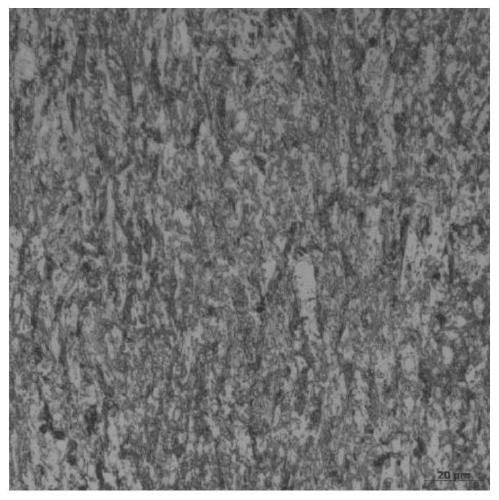

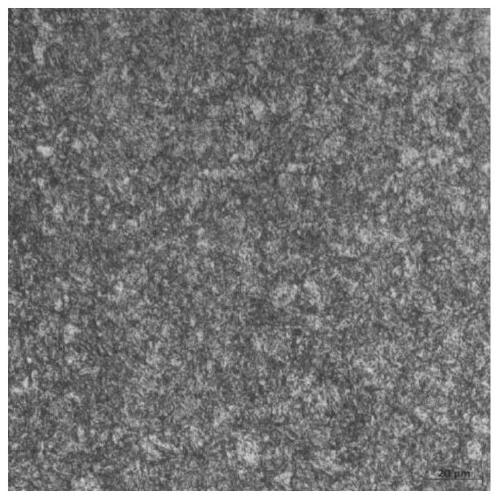

Image

Examples

Embodiment 1

[0029] 1. Steelmaking

[0030] 1. Hot metal pretreatment process

[0031] Pretreatment into the furnace S≤0.005%, P≤0.010% scraping off slag; using fine material scrap.

[0032] 2. Converter process

[0033] The converter pulls carbon once and hits to avoid spot blowing; the ladle is purged with argon gas before tapping to control the tapping port and avoid scattered flow.

[0034] 3. Refining process

[0035] The LF+RH dual-path process is adopted, and the gas content is strictly controlled. It is required to maintain a slight positive pressure in the LF treatment process, strictly control the increase of N in LF, and the amount of N increase is required to be ≤10ppm; LF uses active lime and fluorite to make reducing slag with good fluidity, strictly controls the intensity of argon blowing, and avoids the exposure of molten steel as much as possible; uses silicon Calcium wire Calcium treatment, feed CaSi wire 500 meters, make the inclusions fully spheroidized, and improve...

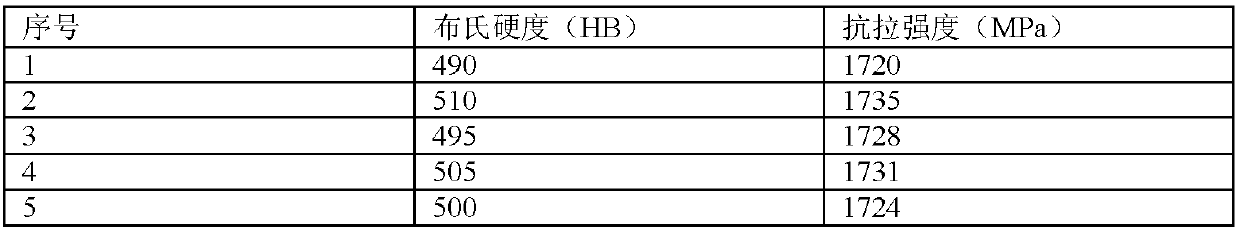

Embodiment 2

[0048] The components, preparation conditions and strength parameters of five groups of steel plates manufactured according to the method described in Example 1 are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com