Concrete curing film covering device for building construction

A technology of building construction and film-covering device, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of affecting the apparent quality of concrete, easily producing surface cracks, and large amount of finishing work, so as to achieve guaranteed strength , prevent the loss of water, improve the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

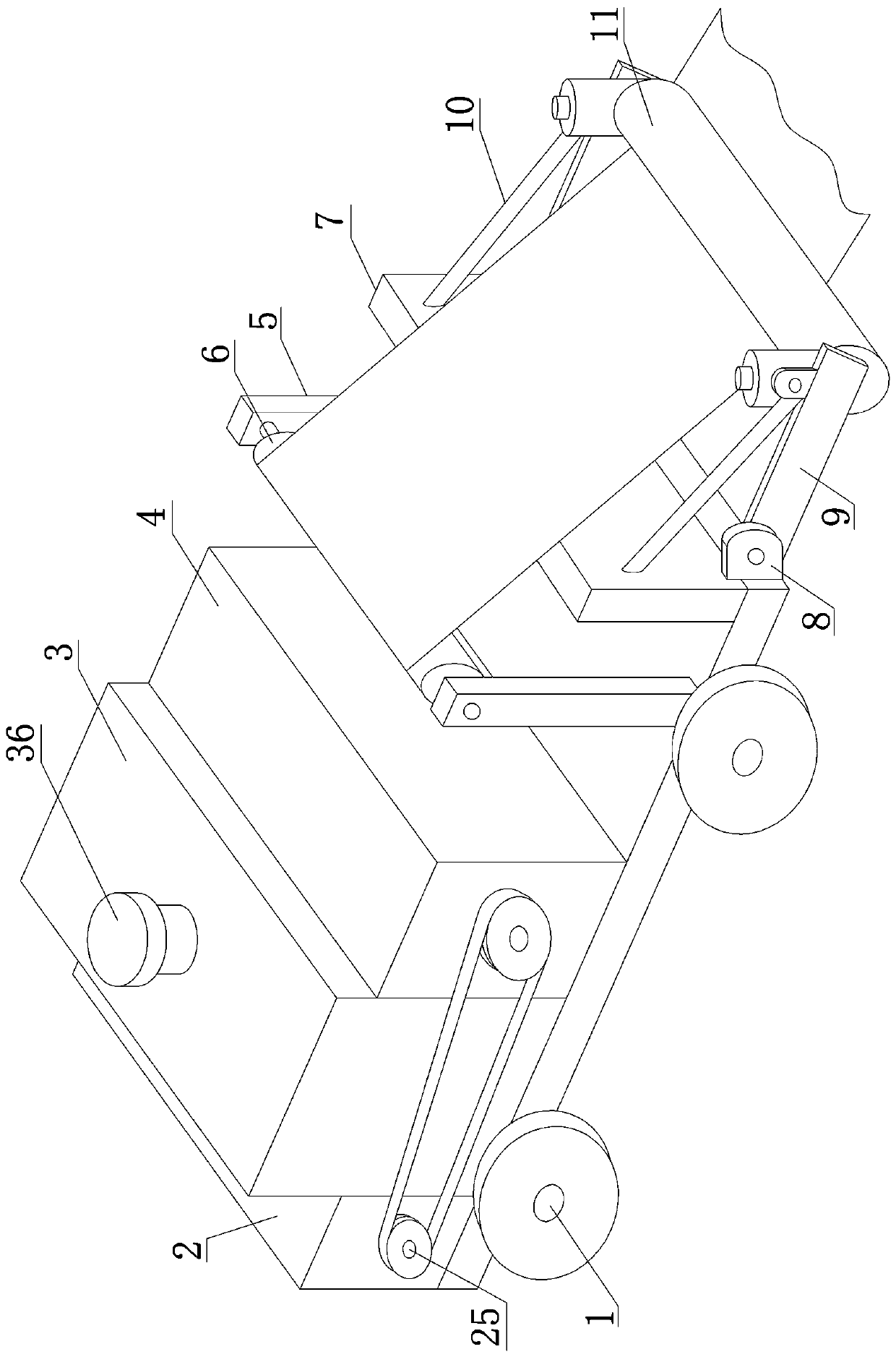

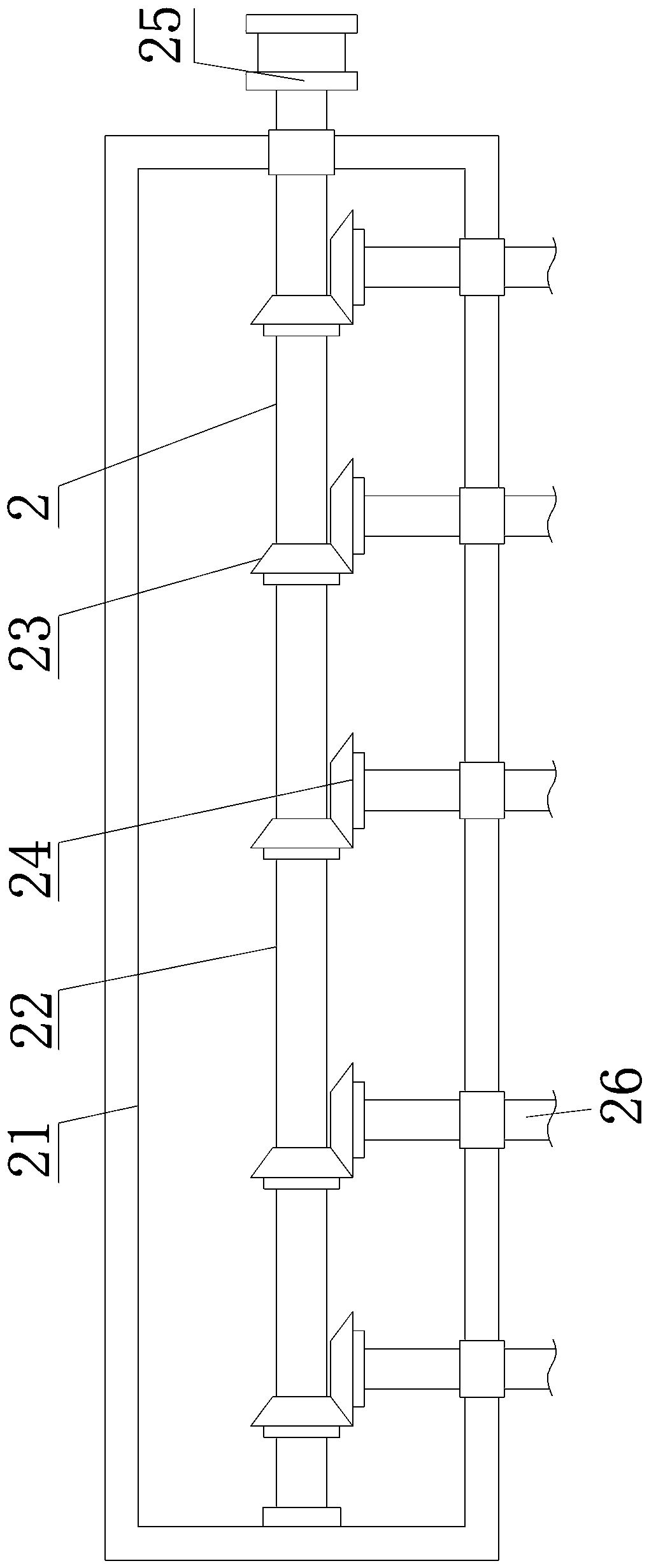

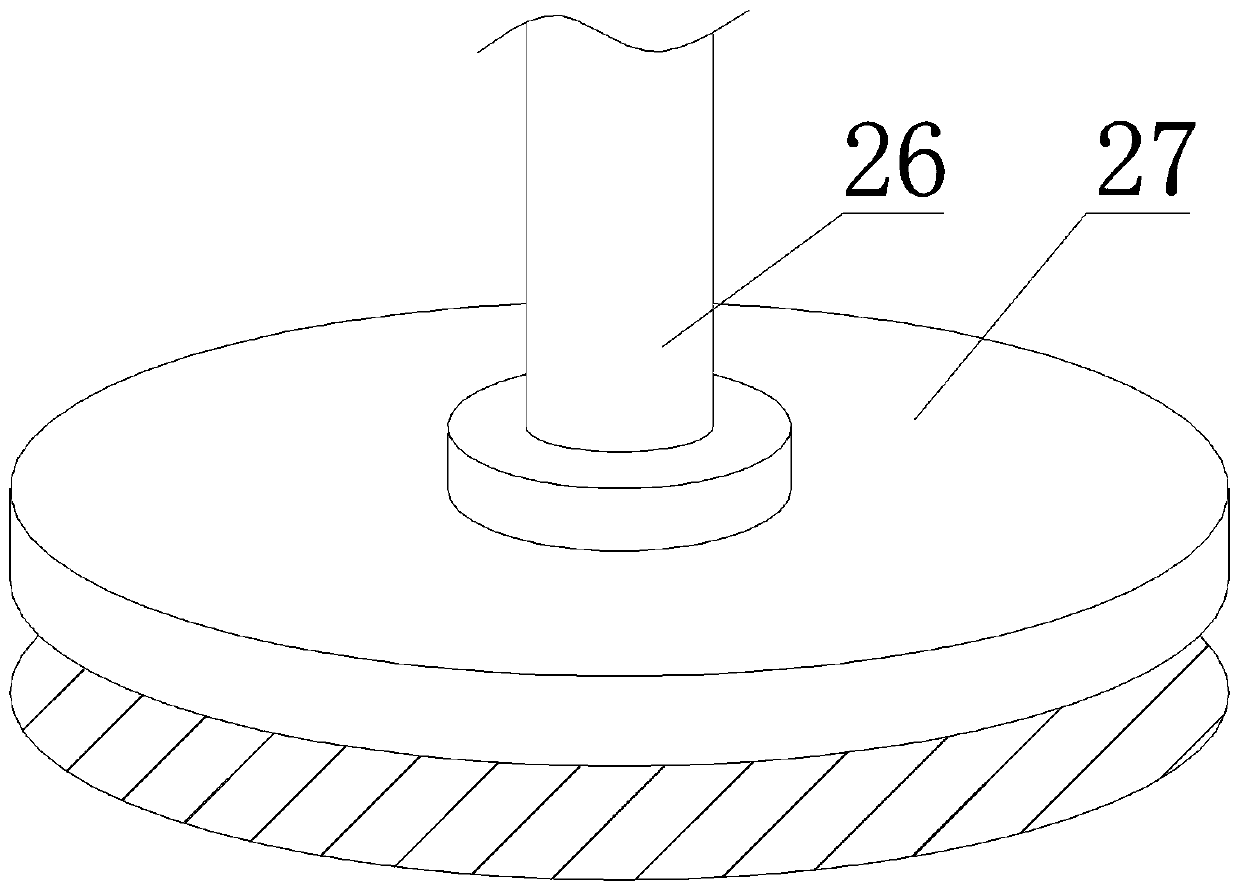

[0027] Such as Figure 1-5 As shown, the present invention provides a technical solution: a concrete curing and coating device for building construction, including a vehicle-mounted traveling device 1, a cleaning mechanism 2, a watering maintenance mechanism 3, a power mechanism 4, a support frame 5, a coating roller 6, Baffle plate 7, hinge block 8, extension plate 9, electric push rod 10 and film-pressing protection device 11, cleaning mechanism 2 is located on the left side of the top of the vehicle-mounted running device 1, and sprinkler maintenance mechanism 3 is located on the top of the vehicle-mounted running device 1, and the sprinkler The maintenance mechanism 3 is located on the right side of the cleaning mechanism 2, the power mechanism 4 is located on the top of the vehicle-mounted running device 1, and the power mechanism 4 is positioned on the right side of the sprinkler maintenance mechanism 3. The bottoms of the two support frames 5 are fixedly connected, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com