Timing Synchronization Method for Distributed Control System of Micro-ignition Dual-fuel Engine

A dual-fuel engine, distributed control technology, applied in engine control, fuel injection control, machine/engine, etc., can solve the problems of difficult to accurately determine delay time, increase program complexity, increase cost input, etc. Strong interference ability, accurate timing positioning, and the effect of suppressing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings:

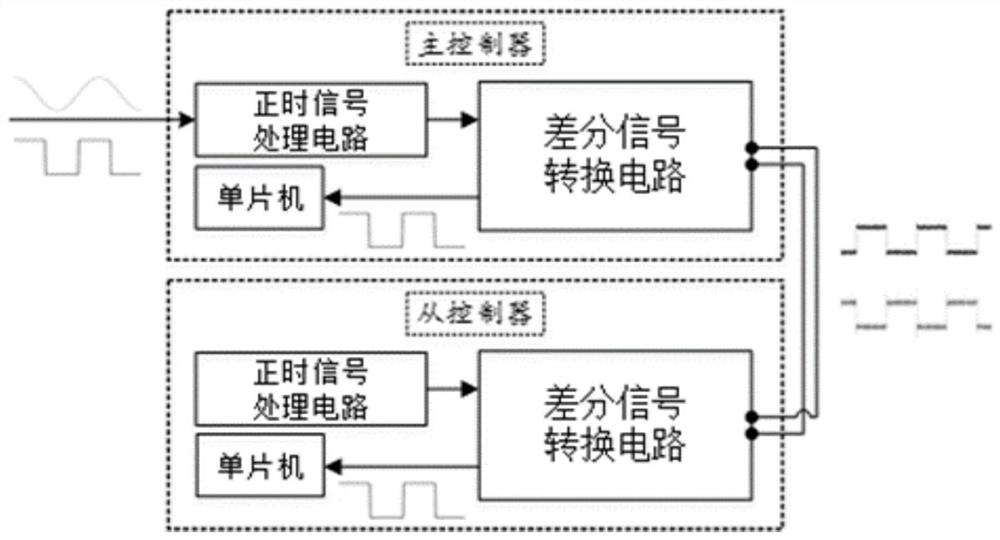

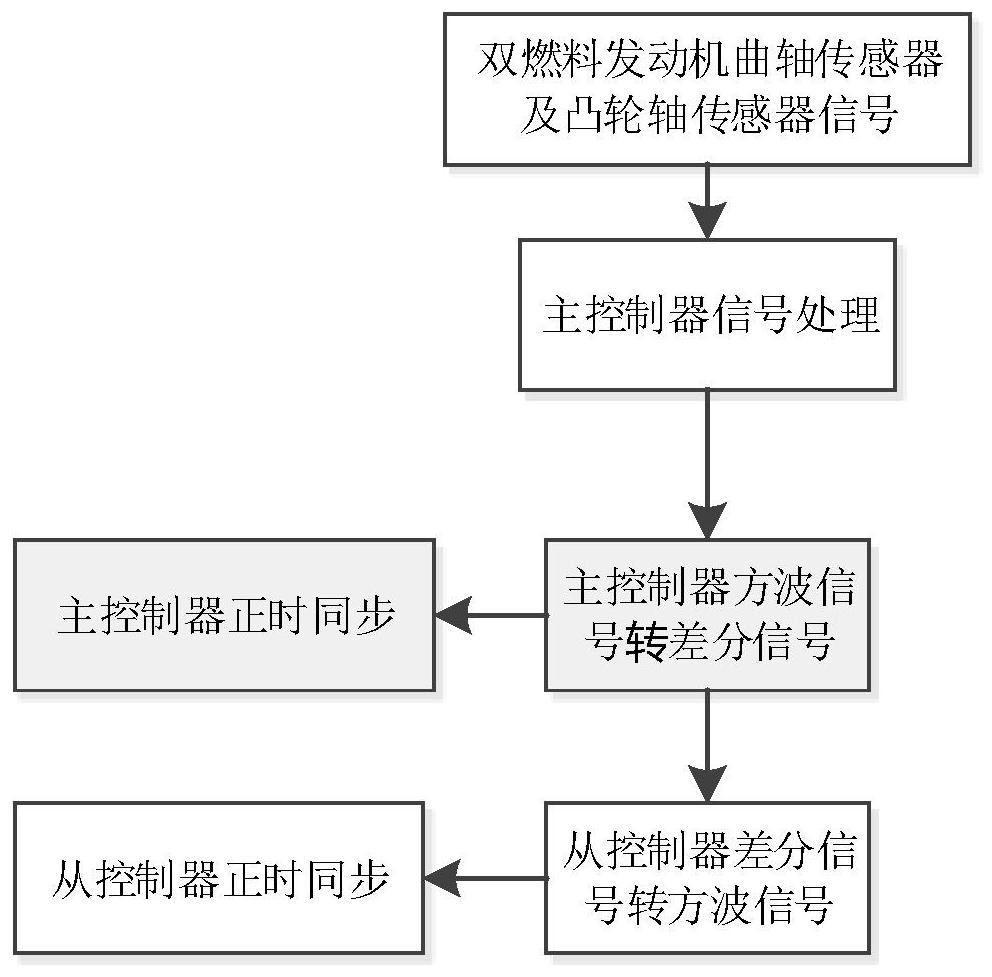

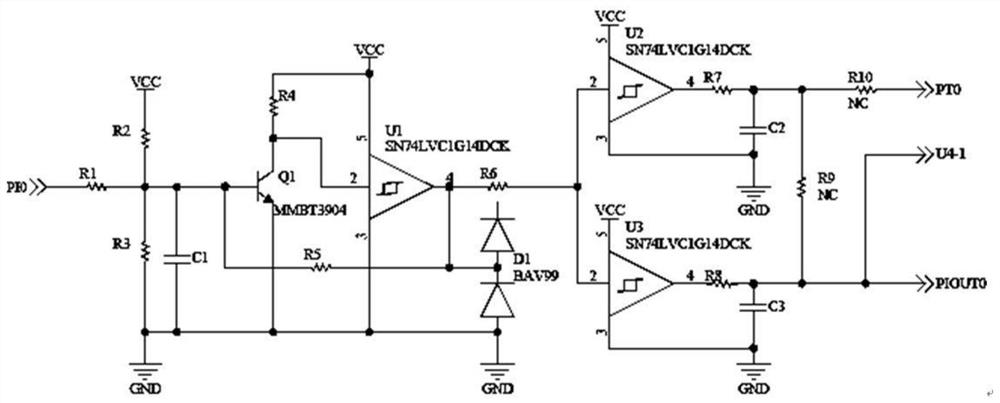

[0022] combine Figure 1-4 , The present invention is a timing synchronization technology method for a micro-ignition dual-fuel engine distributed control system, which converts the timing signal into a differential signal and transmits it between controllers. Differential signal has strong anti-interference ability, can effectively suppress electromagnetic interference, and at the same time time sequence positioning is accurate, which meets the requirements of engine controller for timing signal stability and sensitivity.

[0023] The input end of the main controller timing signal processing circuit is connected with the engine crankshaft sensor or the camshaft sensor; the output end of the main controller timing signal processing circuit is connected with the main controller differential signal conversion circuit; The first output terminal is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com