A method for measuring wall heat flux based on cdte film

A heat flux density and measurement method technology, applied in the direction of material thermal development, material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of limited layout density, high frequency response, low frequency response of thermal resistance, etc., and achieve the sensitivity and accuracy of measurement Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

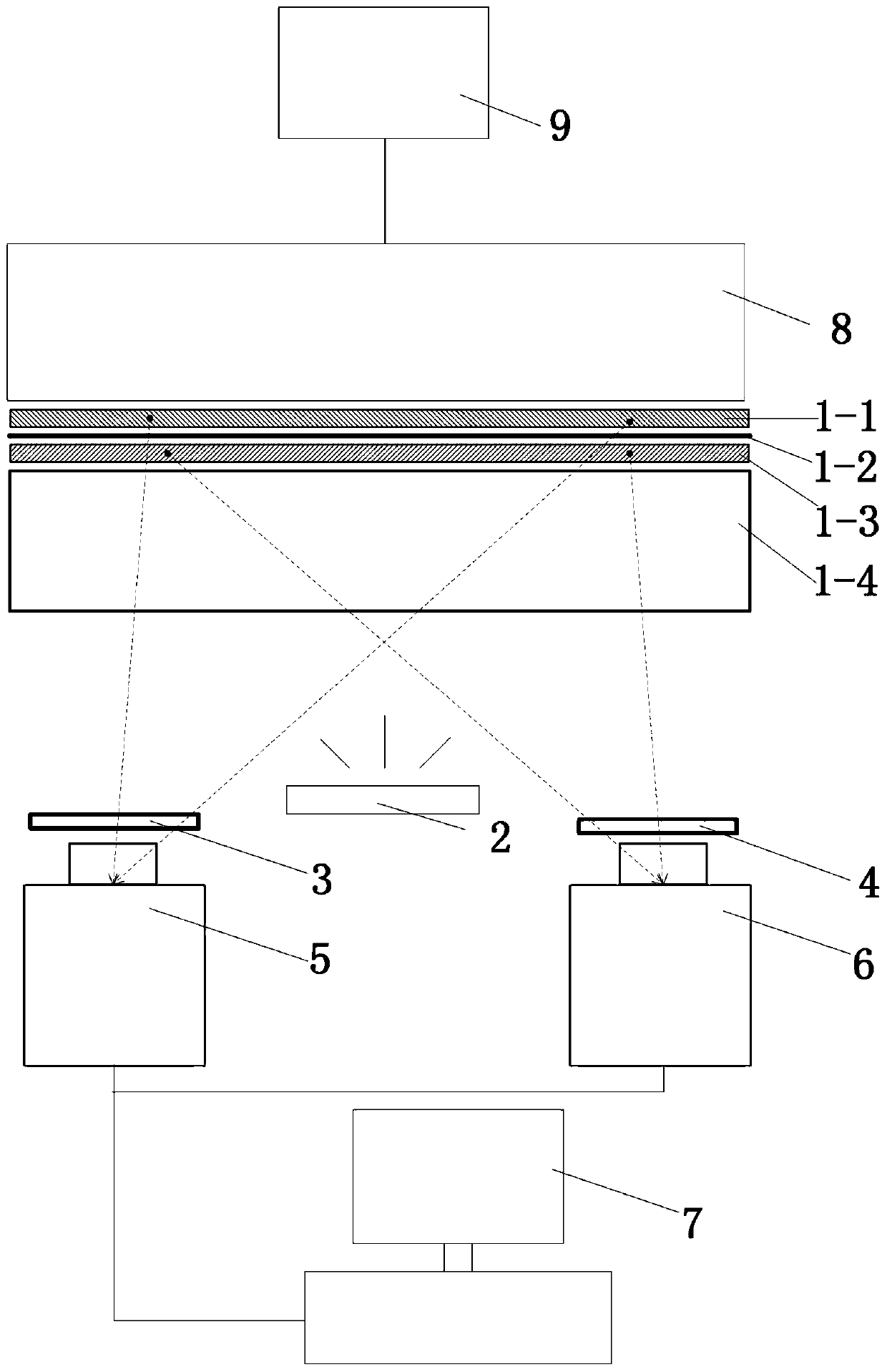

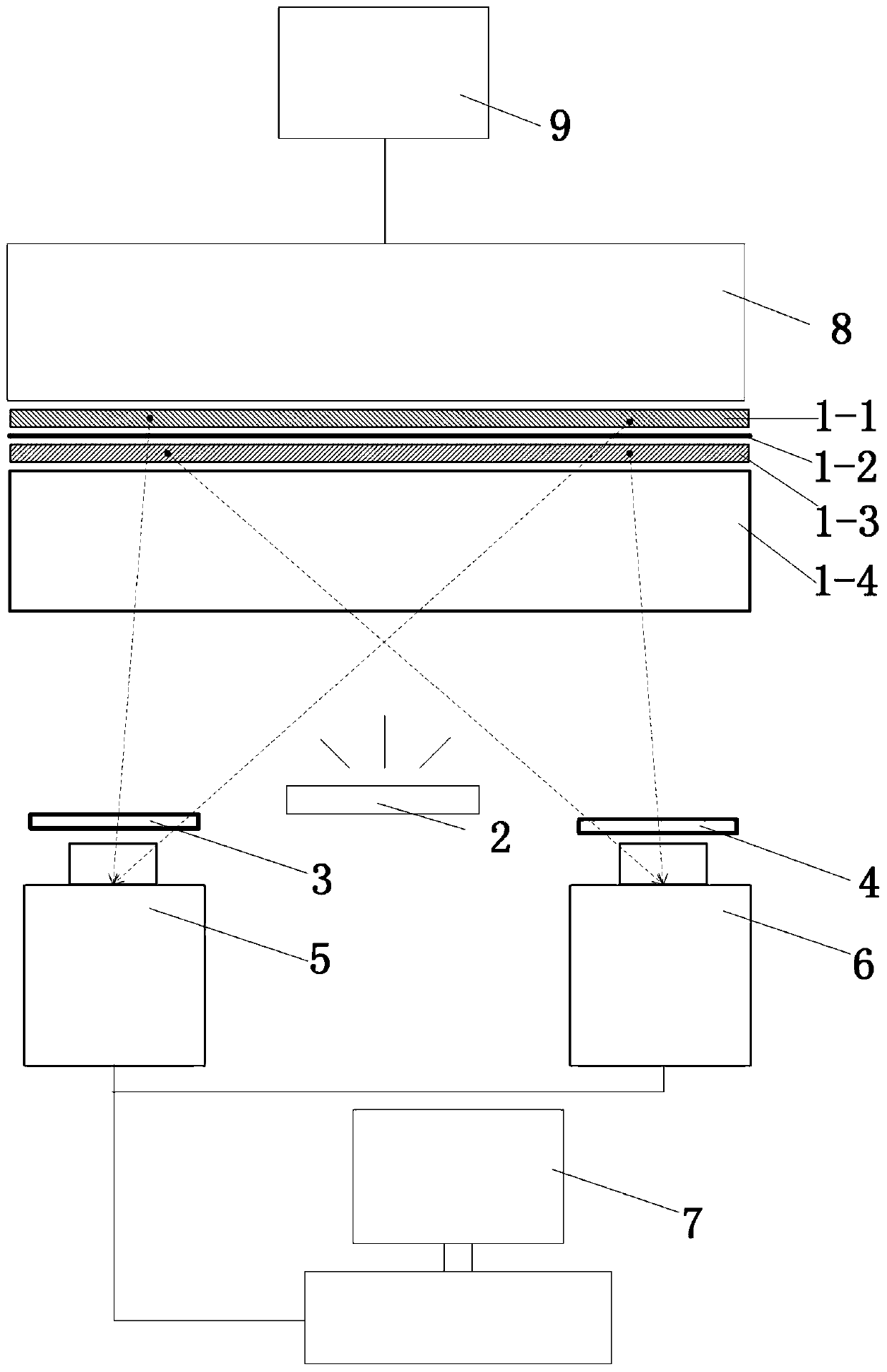

[0026] (1) if figure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a first CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 1 g of gelatin with 6 g of water and heat, then drop 0.3 ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, and heat the mixed solution at 50°C for 15 minutes after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

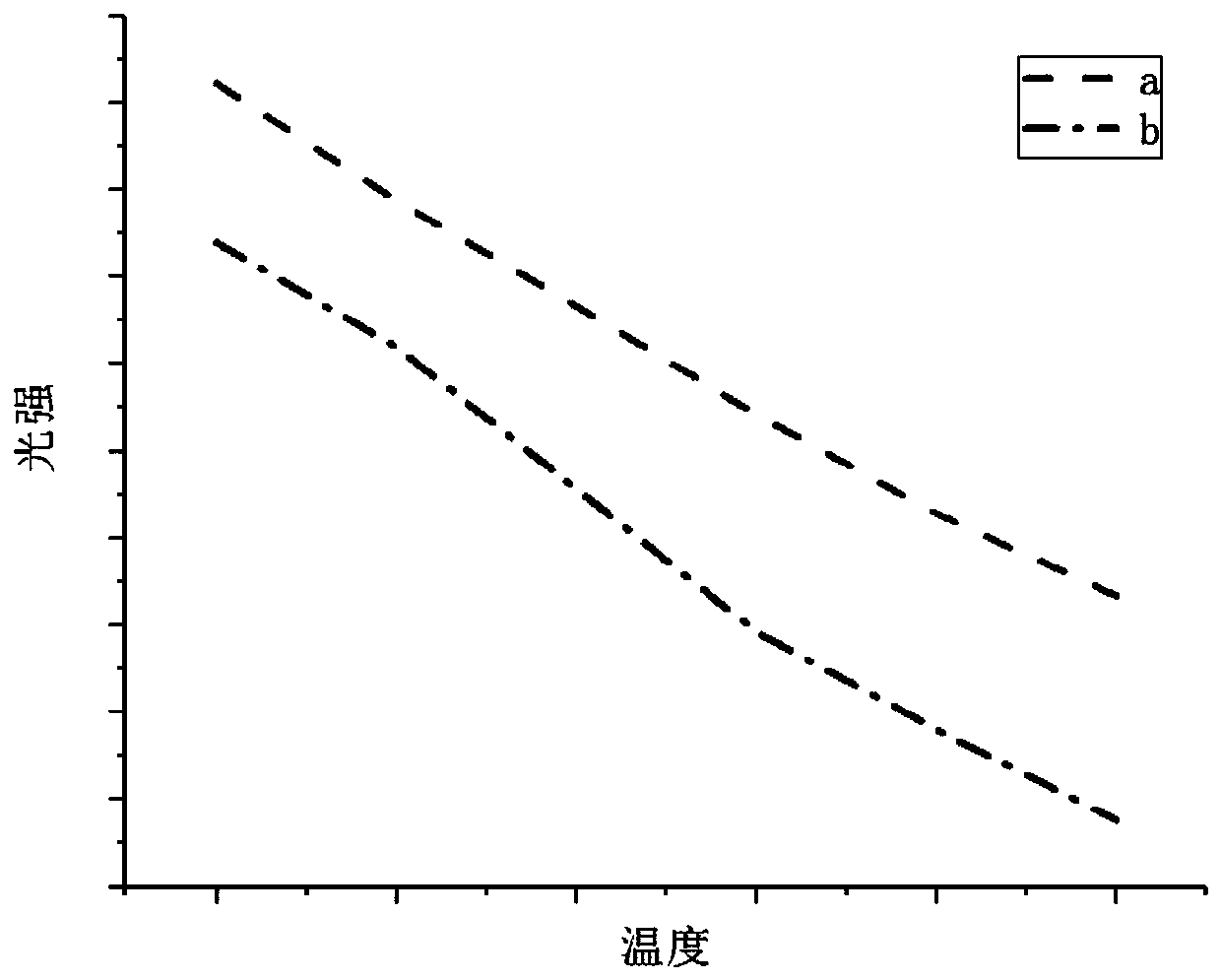

[0027] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, and the luminous intensity of t...

Embodiment 2

[0034] (1) iffigure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a second CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 2 g of gelatin with 16 g of water and heat, then drop 0.8 ml of water-soluble CdTe quantum dots into the gelatin solution, fully shake the mixed solution, and then heat the mixed solution at 70°C for 15 minutes at a constant temperature after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

[0035] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, ...

Embodiment 3

[0042] (1) if figure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a second CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 1 g of gelatin with 10 g of water and heat it, then drop 0.5 ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, and heat the mixed solution at 90°C for 15 minutes after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

[0043] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, and the luminous intensity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com