Method for preparing three-dimensional atom probe sample in rotary mode

An atom probe, rotary technology, applied in the field of micro-nano-scale material sample preparation, can solve the problems of missing sample area, difficult to ensure that the needle tip sample contains the interface of interest, and lack of expected data, etc., to improve the experimental efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

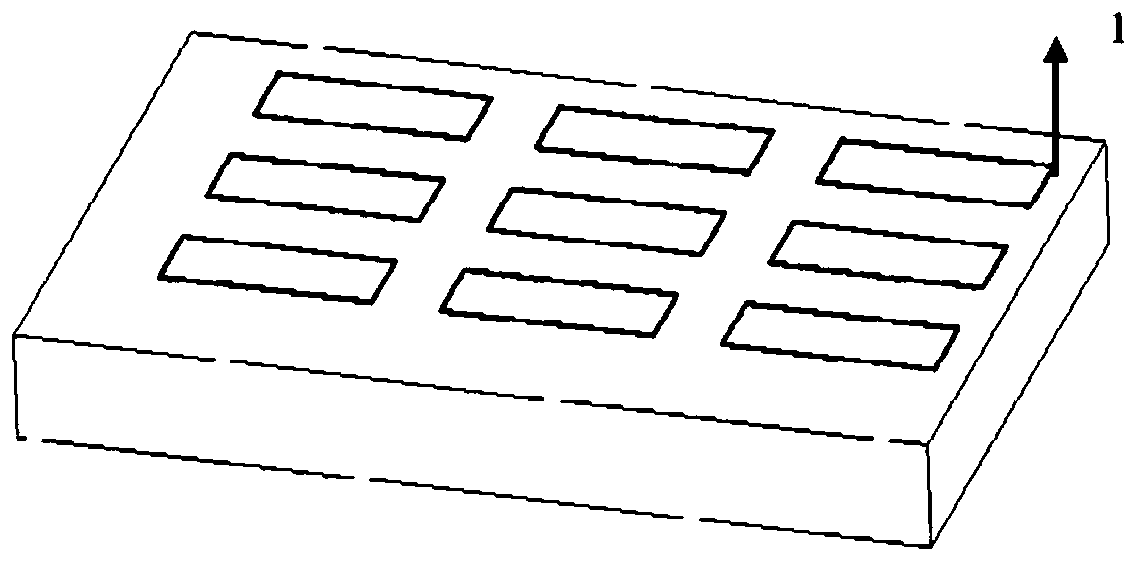

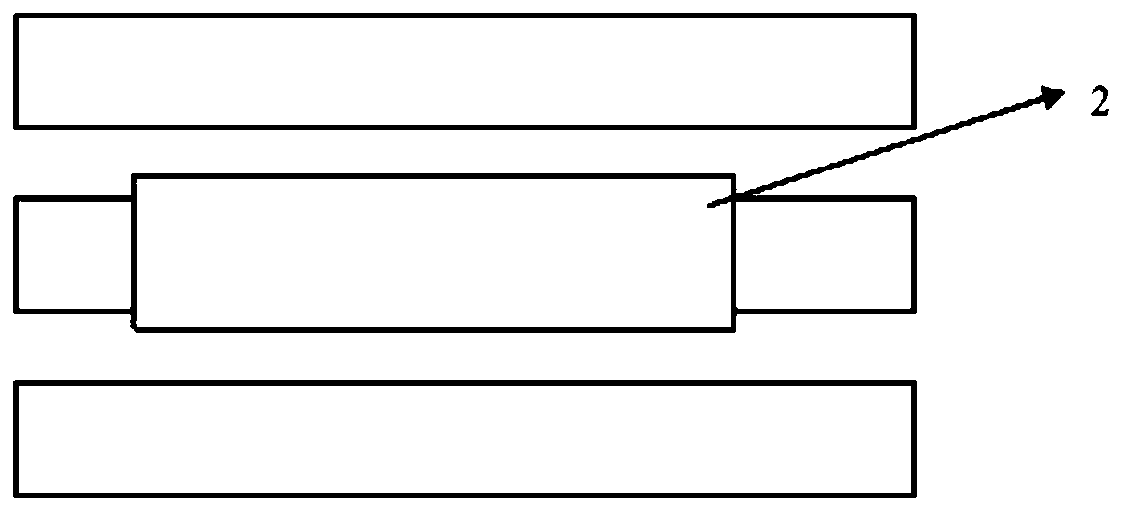

[0054] By using the cross-cut fin structure sample in the fin field effect transistor of the present invention, the three-dimensional atom probe tip sample can be prepared for the fin structure of the fin field effect transistor. This method is different from the traditional method of vertically placing the entire fin structure on a needle tip, but adopts the method of rotating 90° counterclockwise. The fin structure in the semiconductor device is placed perpendicular to the growth direction. The schematic diagram of the present invention is as follows figure 1 shown. Then use the focused ion beam to cut the triangular prism-like strip sample into several small pieces, that is, only a small section of the fin structure is included in each 3D atom probe tip sample, and then cut multiple tip samples for 3D atom probe Technical characterization.

[0055] The following takes the processing of the three-dimensional atom probe tip sample of the fin field effect transistor as an exa...

Embodiment 2

[0078] The invention is also applicable to samples with a layered structure, and can perform three-dimensional atom probe sample preparation on the interface between layers. The sample in this example is a layered alloy formed by a layer of Cr structure and a layer of ZrNiSn structure and the interface formed by the mutual diffusion of the two, as shown in Figure 12(a). The preparation method of the needle tip sample is the same as in Example 1, and the triangular prism-like strip sample is extracted at the interface, as shown in Figure 12(b), and then rotated 90° counterclockwise so that the upper right-angled surface 15 of the strip sample is horizontally upward, while The smooth upper surface 13 of the planar bulk material is perpendicular to the platform surface of the silicon base, so that the slope 14 trimmed on the lower side of the long sample can contact the silicon base, and Pt is deposited on the contact. Such as Figure 13 The interface and sampling points are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com