Near-infrared narrow-band filter and manufacturing method thereof

A technology of narrow-band filter and manufacturing method, which is applied in optics, optical components, instruments, etc., can solve problems such as light reflection, and achieve the effects of low reflection energy intensity and low reflection color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

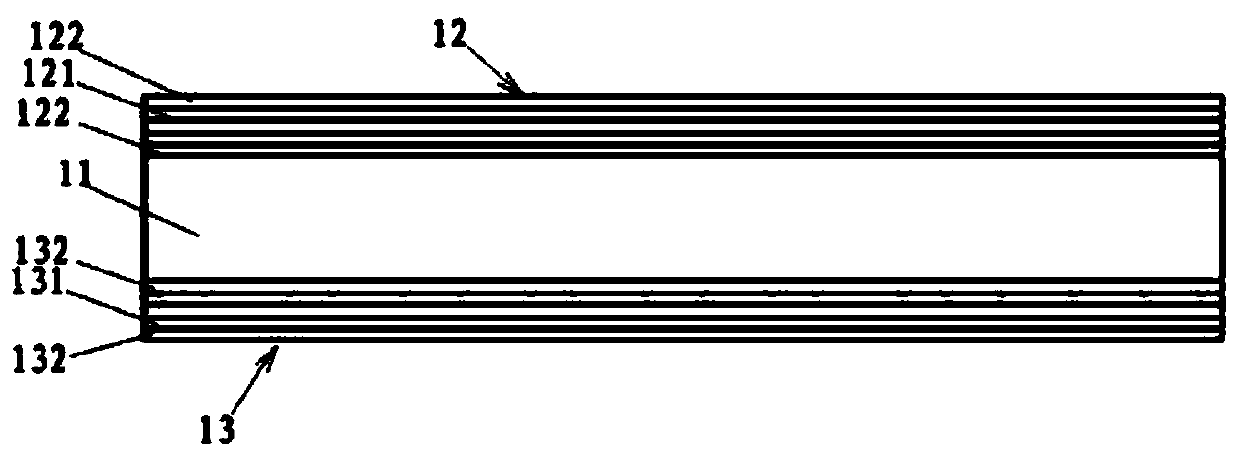

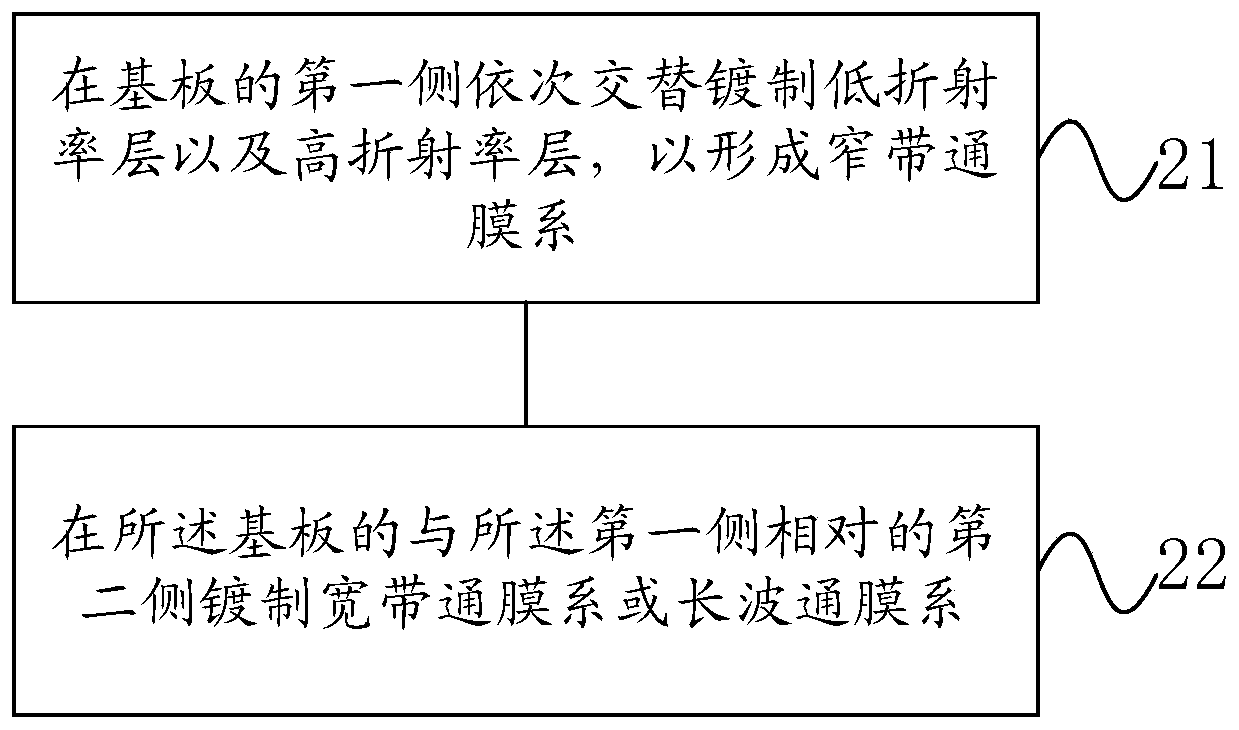

[0062] In the near-infrared narrow-band filter provided in the embodiment of the present application, the second side may be coated with a wide-band pass film system or a long-band pass film system. Table 1a is a film thickness table of a wide band pass film system or a long band pass film system, which reflects the film layer structure of the wide pass film system or long band pass film system of the near-infrared narrow-band filter of the present application. Layers of different thicknesses are alternately plated to form the required film structure. In the structure shown in Table 1a, SiO 2 It is a low refractive index dielectric material, and Si:H is a high refractive index silicon-based material.

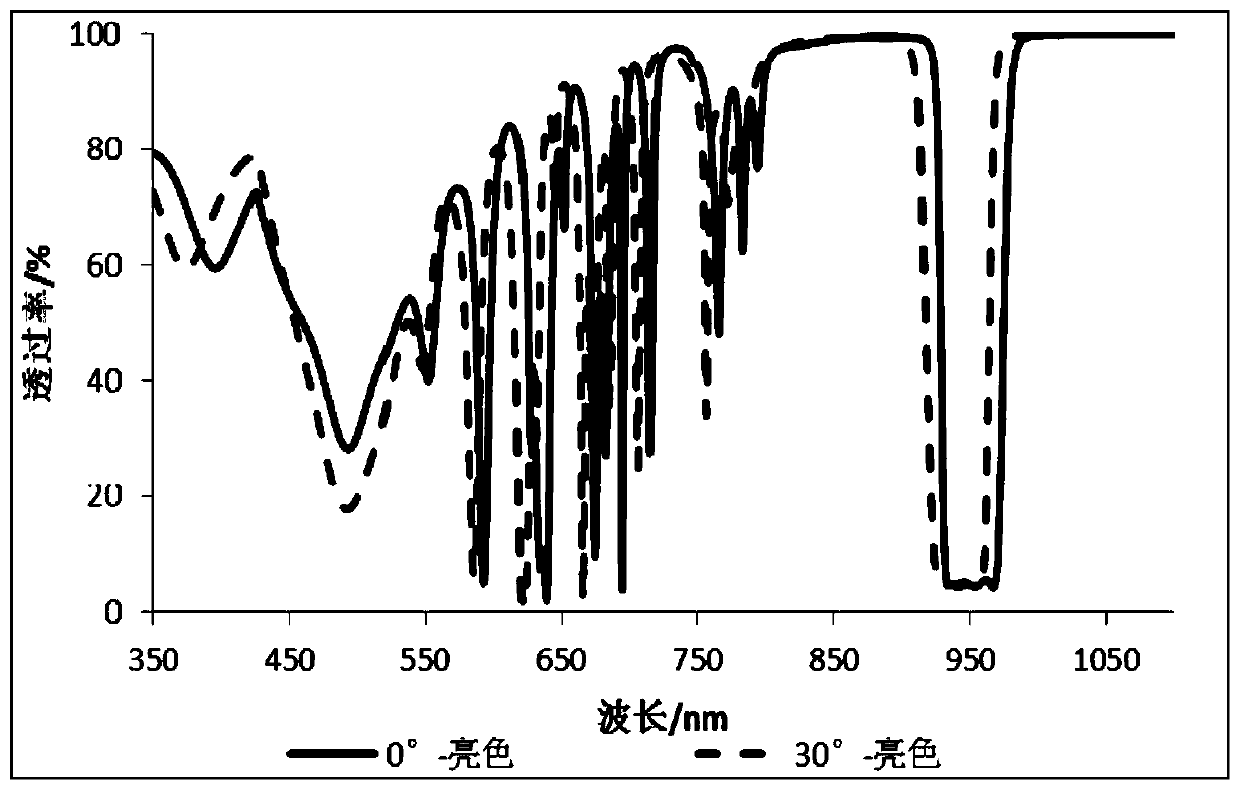

[0063] When the first side of the near-infrared narrow-band filter is coated with a bright reflective color narrow-bandpass film system, the structure shown in Table 1b below can be referred to. Table 1b is a film thickness table of the bright reflective color narrow-band pass...

Embodiment 2

[0073] In the near-infrared narrow-band filter provided in the embodiment of the present application, the second side may be coated with a wide-band pass film system or a long-band pass film system. Table 2a is the film layer thickness table of broadband pass film system or long band pass film system. Layers of different thicknesses are alternately plated to form the required film structure. In the structure shown in Table 2a, SiO 2 It is a low refractive index dielectric material, TiO 2 It is a high refractive index material.

[0074] When the first side of the near-infrared narrow-band filter is coated with a bright reflective color narrow-bandpass film system, the structure shown in Table 2b below can be referred to. Table 2b is the film layer thickness table of the bright reflective color narrow band pass film system, which reflects the film layer structure of the bright reflective color narrow band film system of the narrow band pass film system of the near infrared na...

Embodiment 3

[0084] In the near-infrared narrow-band filter provided in the embodiment of the present application, the second side may be coated with a wide-band pass film system or a long-band pass film system. Table 3a is the film layer thickness table of broadband pass film system or long band pass film system. Layers of different thicknesses are alternately plated to form the required film structure. In the structure shown in Table 1a, SiO 2It is a low refractive index dielectric material, and Si:H is a high refractive index silicon-based material.

[0085] When the first side of the near-infrared narrow-band filter is coated with a bright reflective color narrow-bandpass film system, the structure shown in Table 3b below can be referred to. Table 3b is the film layer thickness table of the bright reflective color narrow-band pass film system, which reflects the film layer structure of the bright reflective color narrow-band film system of the narrow-band pass film system of the near...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com