Automatic single particle irradiation test control system and method

A single-particle irradiation, test control technology, applied in general control systems, control/regulation systems, electronic circuit testing, etc., can solve problems such as not being clearly given, affecting circuit analysis, errors, etc., to improve machine time utilization efficiency, improve accuracy, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

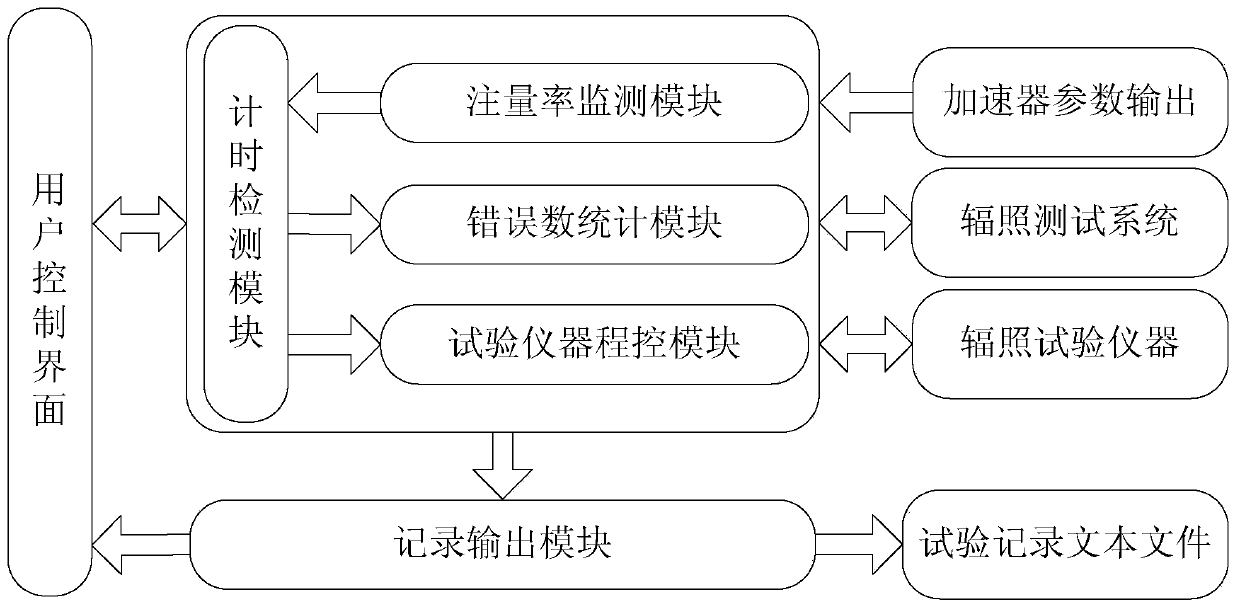

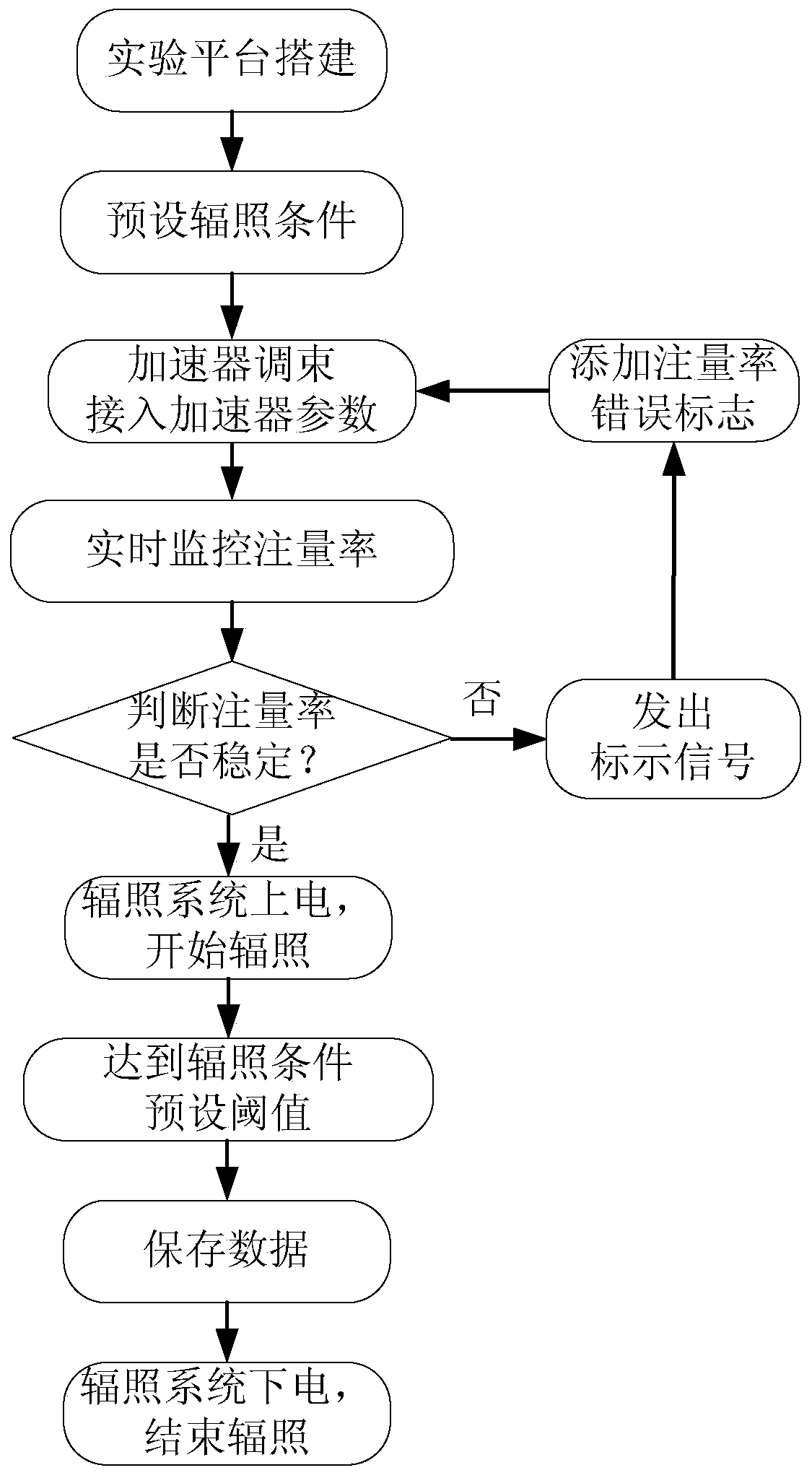

[0073] Such as figure 2 As shown, a specific automated single particle irradiation test process is given, which specifically includes the following steps:

[0074] (1) The test circuit board, program-controlled power supply, signal generator and oscilloscope of the tested chip are built around the particle beam port into a single particle irradiation test platform. Each test instrument is connected and controlled through the network port.

[0075] (2) After the platform is built, set the threshold of the irradiation conditions. When the single event flip test of the trigger is performed, set the single event flip error number threshold of the trigger to 100, and the total fluence threshold of the particles 10 7 ions / cm 2 , As long as one of them is reached, it means that the irradiation conditions are met;

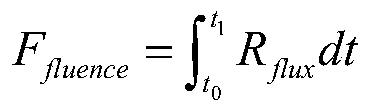

[0076] (3) The accelerator performs the adjustment and preparation of the single particle beam, and the system is connected to the fluence rate output interface of the acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com