Method for preparing in-situ Ni-doped Co-MOF-74 supercapacitor electrode material

A supercapacitor, co-mof-74 technology, applied in the field of electrochemical energy storage, can solve the problems of cumbersome steps, poor conductivity of MOFs, unsuitable for industrial production, etc., and achieve the effects of simple operation, low cost, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

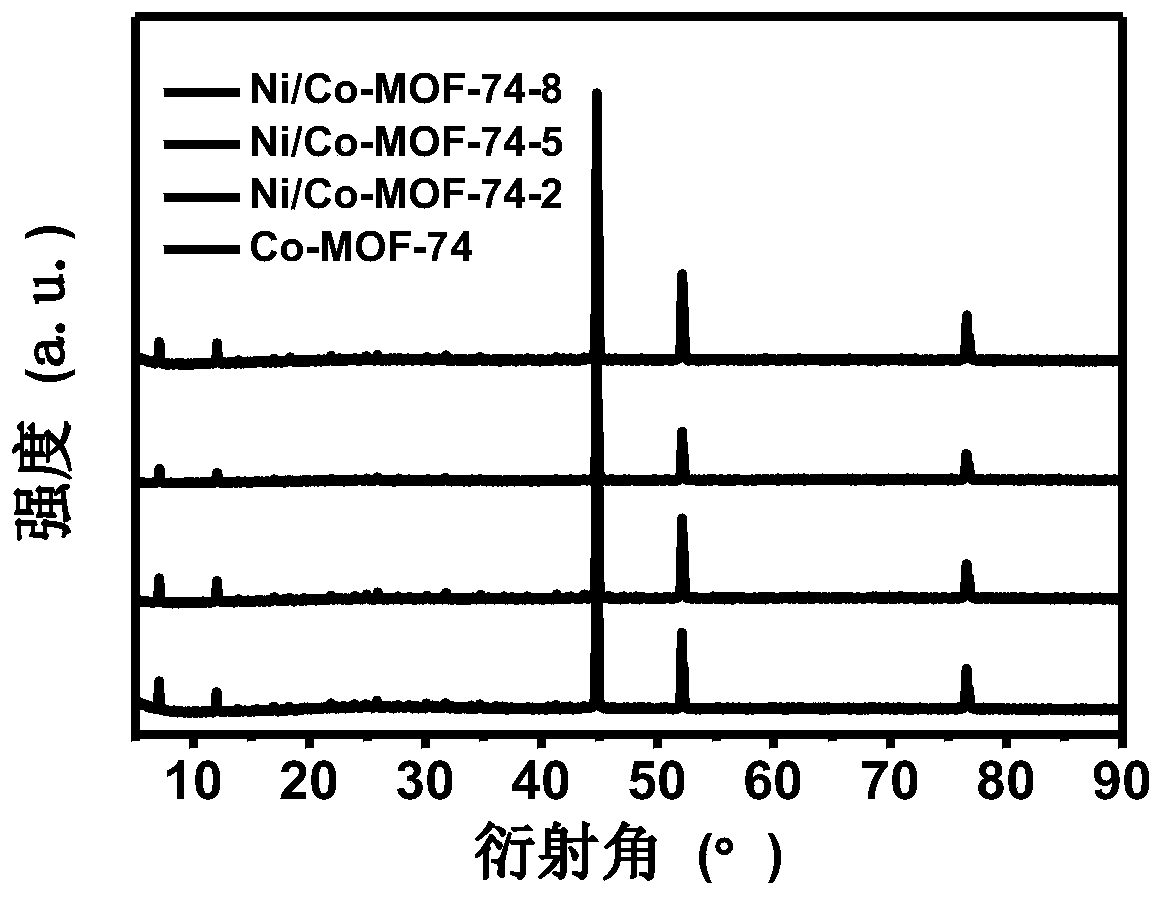

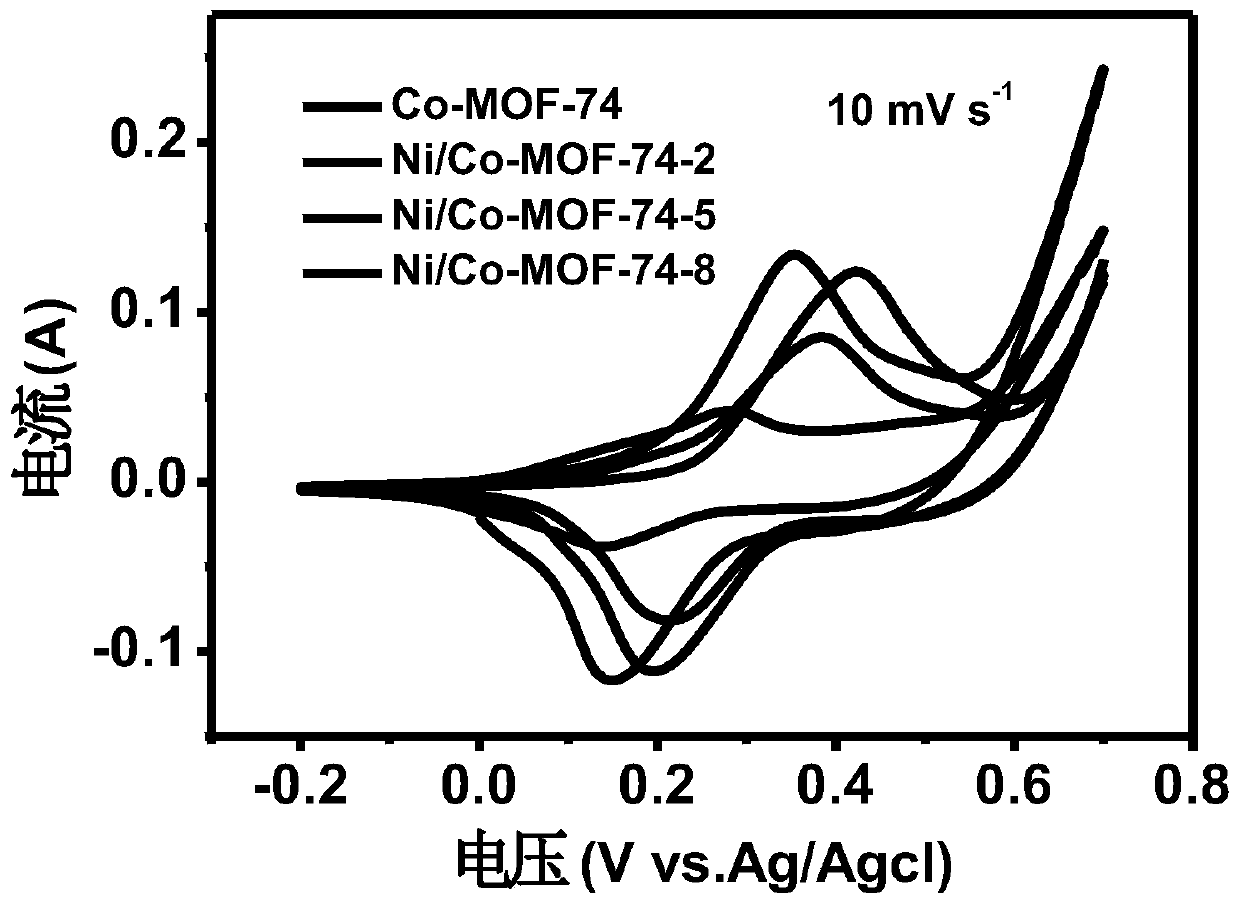

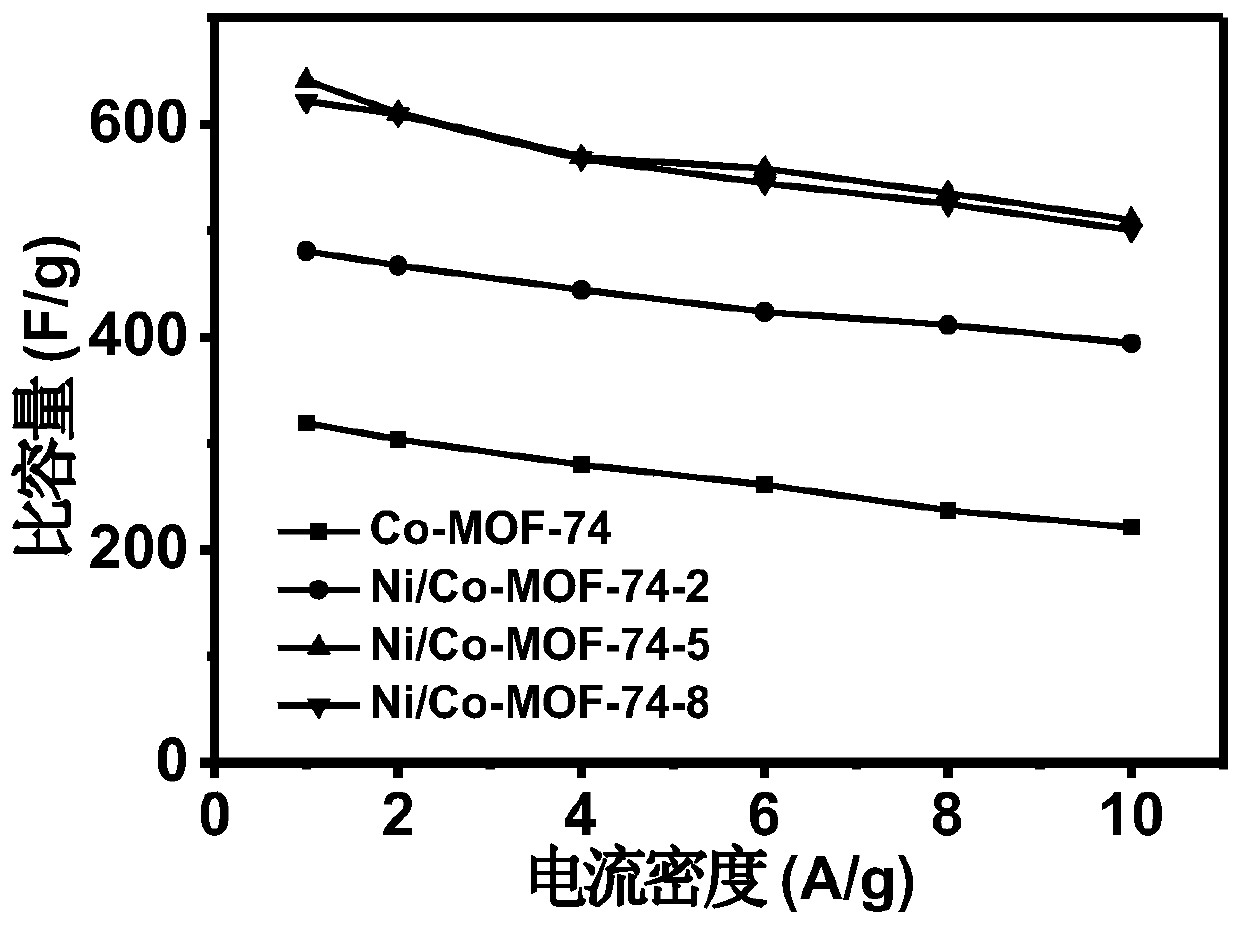

[0032] A kind of preparation method of in-situ Ni-doped Co-MOF-74 supercapacitor electrode material, comprises steps as follows:

[0033] Co-MOF-74 was synthesized by in situ growth method: 0.75g of cobalt nitrate and 0.1825g of 2.5-dihydroxyterephthalic acid were dissolved in 60mL of N.N-dimethylformamide, and the clear solution was obtained by ultrasonic oscillation for 10min , then add 3.6mL water and 3.6mL ethanol, continue to shake for 20min, then add the solution into the inner tank of the reactor, place the cleaned foam nickel vertically in the inner tank, then put it into the reactor, React at a temperature of 120°C for 24 hours, cool naturally to room temperature, open the reactor, take the sample out of the reactor, wash it repeatedly with deionized water and absolute ethanol, and dry it in a vacuum oven at 60°C for 24 hours , and finally the sample was taken out to obtain pure Co-MOF-74.

[0034] Co-MOF-74 is used as working electrode, platinum sheet is used as aux...

Embodiment 2

[0036] A kind of preparation method of in-situ growth Ni-doped Co-MOF-74 supercapacitor electrode material, comprises steps as follows:

[0037]Ni / Co-MOF-74 was synthesized by in situ growth method: 0.75g of cobalt nitrate, 0.15g of nickel nitrate, and 0.1825g of 2.5-dihydroxyterephthalic acid were dissolved in 60mL of N.N-dimethylformamide, Ultrasonic vibration for 10 minutes to obtain a clear solution, then add 3.6mL of water and 3.6mL of ethanol, continue to shake for 20min, then add the solution into the inner tank of the reaction kettle, place the cleaned foam nickel vertically in the inner tank, and then put Put it into the reaction kettle, react at a temperature of 120°C for 24 hours, cool naturally to room temperature, open the reaction kettle, take the sample out of the reaction kettle, wash it repeatedly with deionized water and absolute ethanol, Dry in a vacuum oven for 24 hours, and finally take out the sample to obtain Ni / Co-MOF-74.

[0038] Ni / Co-MOF is used as ...

Embodiment 3

[0040] A kind of preparation method of in-situ growth Ni-doped Co-MOF-74 supercapacitor electrode material, comprises steps as follows:

[0041] Ni / Co-MOF-74 was synthesized by in situ growth method: 0.75g of cobalt nitrate, 0.375g of nickel nitrate, and 0.1825g of 2.5-dihydroxyterephthalic acid were dissolved in 60mL of N.N-dimethylformamide, respectively. Ultrasonic vibration for 10 minutes to obtain a clear solution, then add 3.6mL of water and 3.6mL of ethanol, continue to shake for 20min, then add the solution into the inner tank of the reaction kettle, place the cleaned foam nickel vertically in the inner tank, and then put Put it into the reaction kettle, react at a temperature of 120°C for 24 hours, cool naturally to room temperature, open the reaction kettle, take the sample out of the reaction kettle, wash it repeatedly with deionized water and absolute ethanol, Dry in a vacuum oven for 24 hours, and finally take out the sample to obtain Ni / Co-MOF-74.

[0042] Ni / Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com