Bionic shell-type breathing monitoring friction nano-generator and preparation method thereof

A nano-generator and respiratory monitoring technology, which is applied in the direction of friction generator and respiratory organ evaluation, can solve the problems of high energy consumption, inability to realize self-powered breathing behavior monitoring, and large dependence on external power supply, and achieve low material requirements, Break through the limitations of flexible sensors and achieve low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

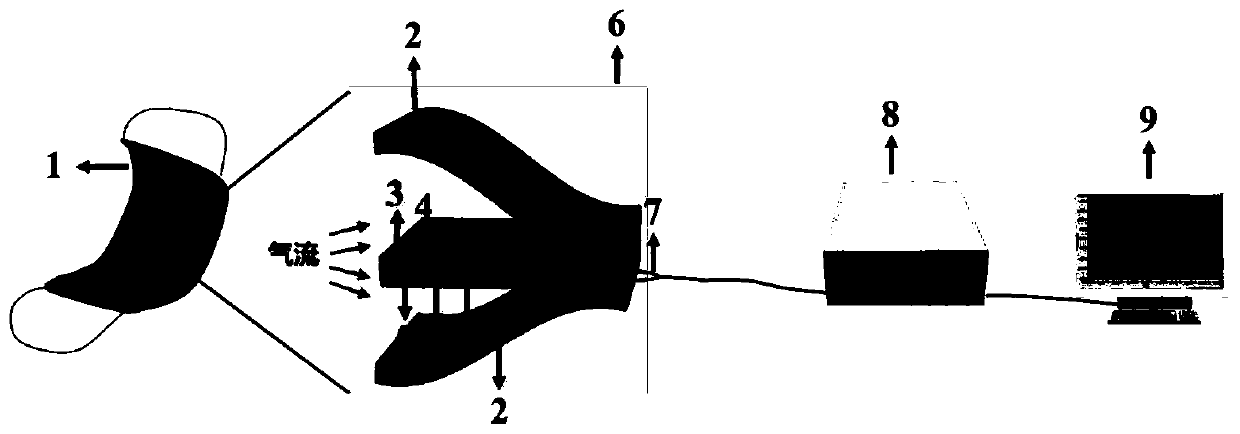

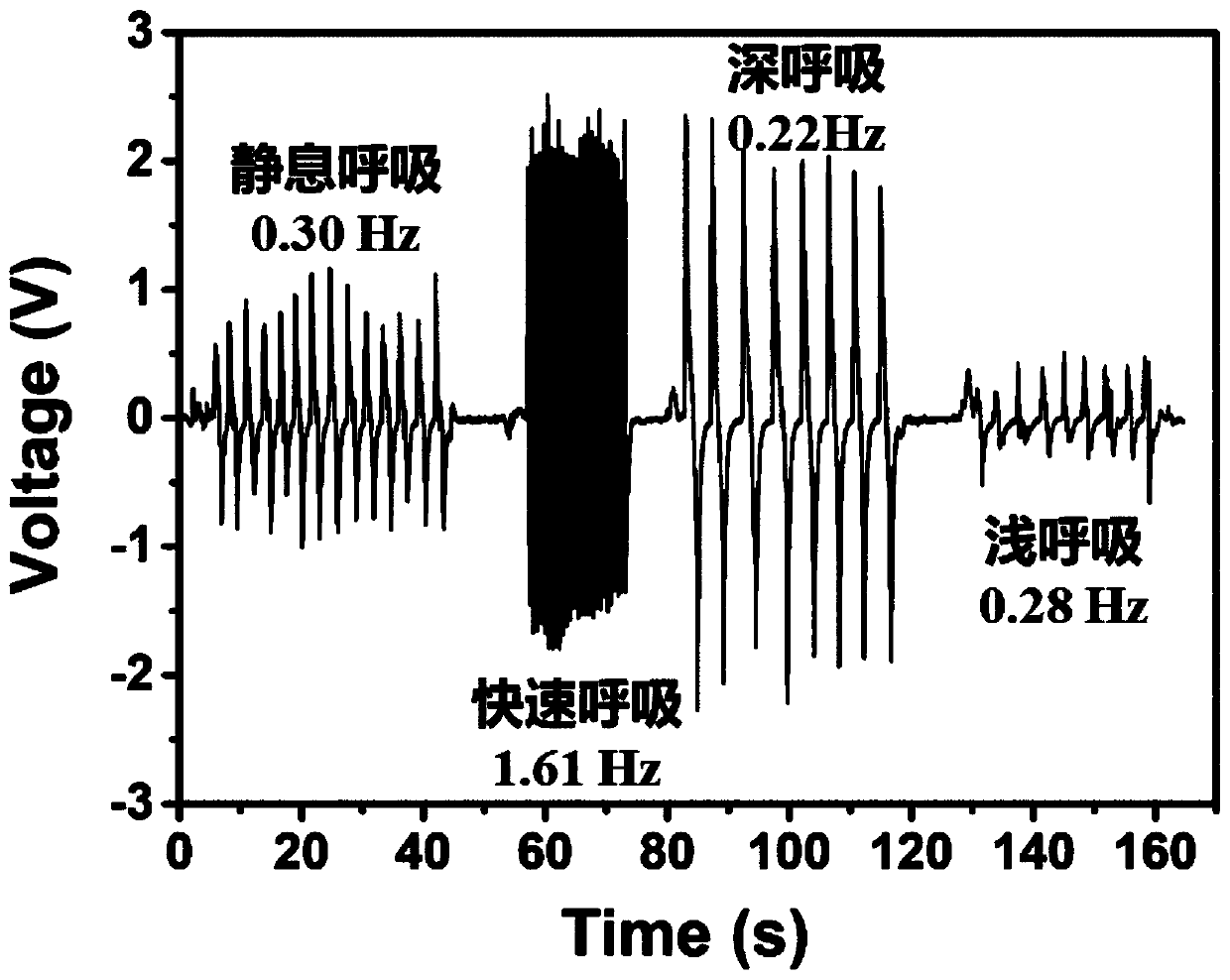

[0040] A bionic shell-type respiration monitoring triboelectric nanogenerator, comprising friction material one 3 and friction material two 2 with different triboelectric sequences, and also includes an insulating layer 5 and an electrode layer 4 for conducting electricity, above the insulating layer 5 or The first friction material 3 and the second friction material 2 are provided below, the first friction material 3 is connected to one end of the second friction material 2, and is arranged above or below the insulating layer 5, the first friction material 3 and the second friction material 2 is provided with an included angle of 5-20°, and the opening angle of the included angle is opposite to the breathing outlet, and the non-connection of the friction material 3 and the friction material 2 can be separated, contacted and rubbed. The electrode layer 4 is disposed on the side of the first friction material 3 away from the second friction material 2 .

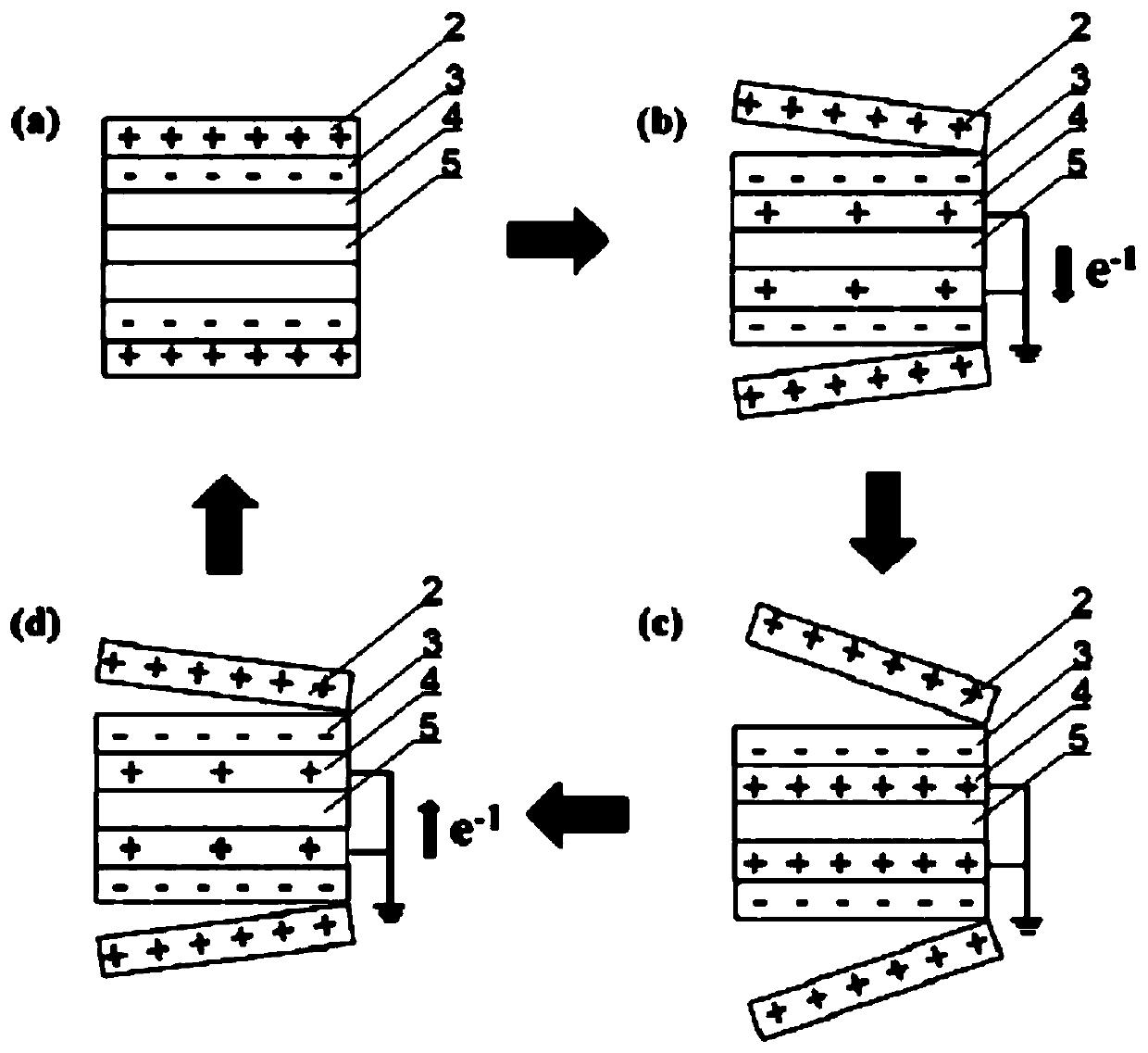

[0041] Working princip...

Embodiment 2

[0044] This embodiment is based on embodiment 1, further, as figure 1 , the insulating layer 5 is made of PET material, friction material 1 3 and friction material 2 are provided on the top of the insulating layer 5, and friction material 1 3 and friction material 2 are also provided below the insulating layer 5 2. The friction material one 3 is made of nylon film, the friction material two 2 is made of polytetrafluoroethylene film, the upper surface and the lower surface of the insulating layer 5 are respectively provided with electrode layers 4, and the electrode layers 4. Made of aluminum foil, the upper surface of the electrode layer 4 located on the upper surface of the insulating layer 5 and the lower surface of the electrode layer 4 located on the lower surface of the insulating layer 5 are respectively provided with a friction material-3, and the friction material-3 of the upper and lower layers The same end is respectively connected to the friction material 2 2, and a...

Embodiment 3

[0047] This embodiment is based on embodiment 1, further, as Figure 5 , the upper surface and the lower surface of the insulating layer 5 are respectively provided with friction material two 2, the insulating layer 5 is made of organic film material, the friction material one 3 is made of nylon film material, and the friction material two 2 is made of polyamide Made of vinyl fluoride film, an included angle 1 is set between the friction material 2 of the upper and lower layers, one end of the upper surface of the friction material 2 of the upper layer is connected with a friction material 3, and the lower surface of the friction material 2 of the lower layer is And the same end as the friction material 2 of the upper layer is also provided with a friction material 3, each layer of the friction material 3 is provided with an electrode layer 4 on the side away from the friction material 2 respectively, and the connected The friction material 1 3 and the friction material 2 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com