Gradient Drying Method of White Pepper

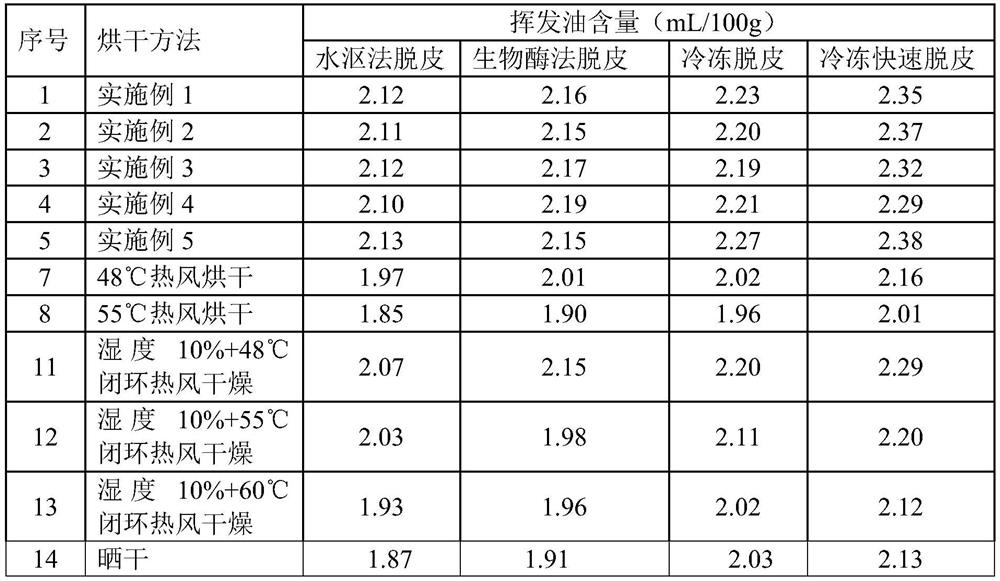

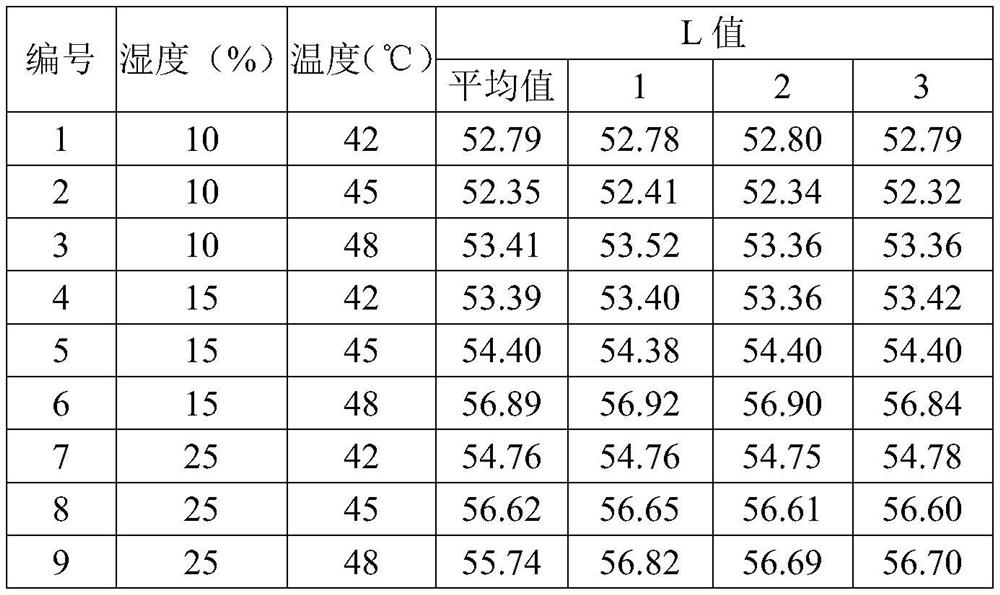

A gradient drying and white pepper technology, applied in food drying, food science, etc., can solve the problems of not considering dehumidification and ultraviolet light irradiation, affecting the aroma and color of white pepper, easily mixed with dust, microorganisms, etc., to achieve good appearance quality, Avoid energy loss, the effect of high whiteness L value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for gradient drying of white pepper, comprising the following steps:

[0025] (1) Take the peeled wet peppercorns, wash and drain them, and spread them evenly in the closed-loop hot air drying device, with a thickness of 1 layer of peppercorns;

[0026] (2) In the closed-loop hot air drying device, ultraviolet lamps are set on the side walls and the top, and the intensity of the ultraviolet lamps is 4.8KJ / m2; the initial drying temperature is set to 45°C, the humidity is set to 15%, and dried for 2 hours, so that the Moisture content is reduced to below 30%;

[0027] (3) Set the drying temperature to 50°C, continue drying for 5 hours, and control the humidity in the closed-loop hot air drying device to decrease from 25% to 10% until the moisture content in the peppercorns is not higher than 13%.

[0028] In this embodiment, the humidity is set to 4 decreasing gradients, namely: 25%, 20%, 15% and 5%, and each humidity gradient is maintained for 1h, 1h, 1h, and ...

Embodiment 2

[0030] A method for gradient drying of white pepper, comprising the following steps:

[0031] (1) Take the peeled wet peppercorns, wash and drain them, and spread them evenly in the closed-loop hot air drying device, with a thickness of 2 layers of peppercorns;

[0032] (2) In the closed-loop hot air drying device, ultraviolet lamps are set on the side walls and the top, and the intensity of the ultraviolet lamps is 7.2KJ / m 2 ; The initial drying temperature is set to 48°C, the humidity is set to 25%, and dried for 3 hours to reduce the moisture content of the peppercorns to below 30%;

[0033] (3) Set the drying temperature to 55°C, continue drying for 4 hours, and control the humidity in the closed-loop hot air drying device to decrease from 25% to 10% until the water in the peppercorns is not higher than 13%.

[0034] In this embodiment, the humidity is set to 4 decreasing gradients, namely: 25%, 20%, 15% and 5%, and each humidity gradient is maintained for 1h, 1h, 1h, and...

Embodiment 3

[0036] A method for gradient drying of white pepper, comprising the following steps:

[0037] (1) Take the peeled wet peppercorns, wash and drain them, and spread them evenly in the closed-loop hot air drying device, with a thickness of 3 layers of peppercorns;

[0038] (2) In the closed-loop hot air drying device, ultraviolet lamps are set on the side walls and the top, and the intensity of the ultraviolet lamps is 7.2KJ / m 2 ; The initial drying temperature is set to 45°C, the humidity is set to 25%, and the drying is performed for 2.5h to reduce the moisture content of the peppercorns to below 30%;

[0039] (3) Set the drying temperature to 52°C, continue drying for 6 hours, and control the humidity in the closed-loop hot air drying device to decrease from 25% to 10% until the moisture content in the peppercorns is not higher than 13%.

[0040] In this embodiment, the humidity is set to 5 decreasing gradients, respectively: 25%, 20%, 15%, and 5%, and each humidity gradient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com