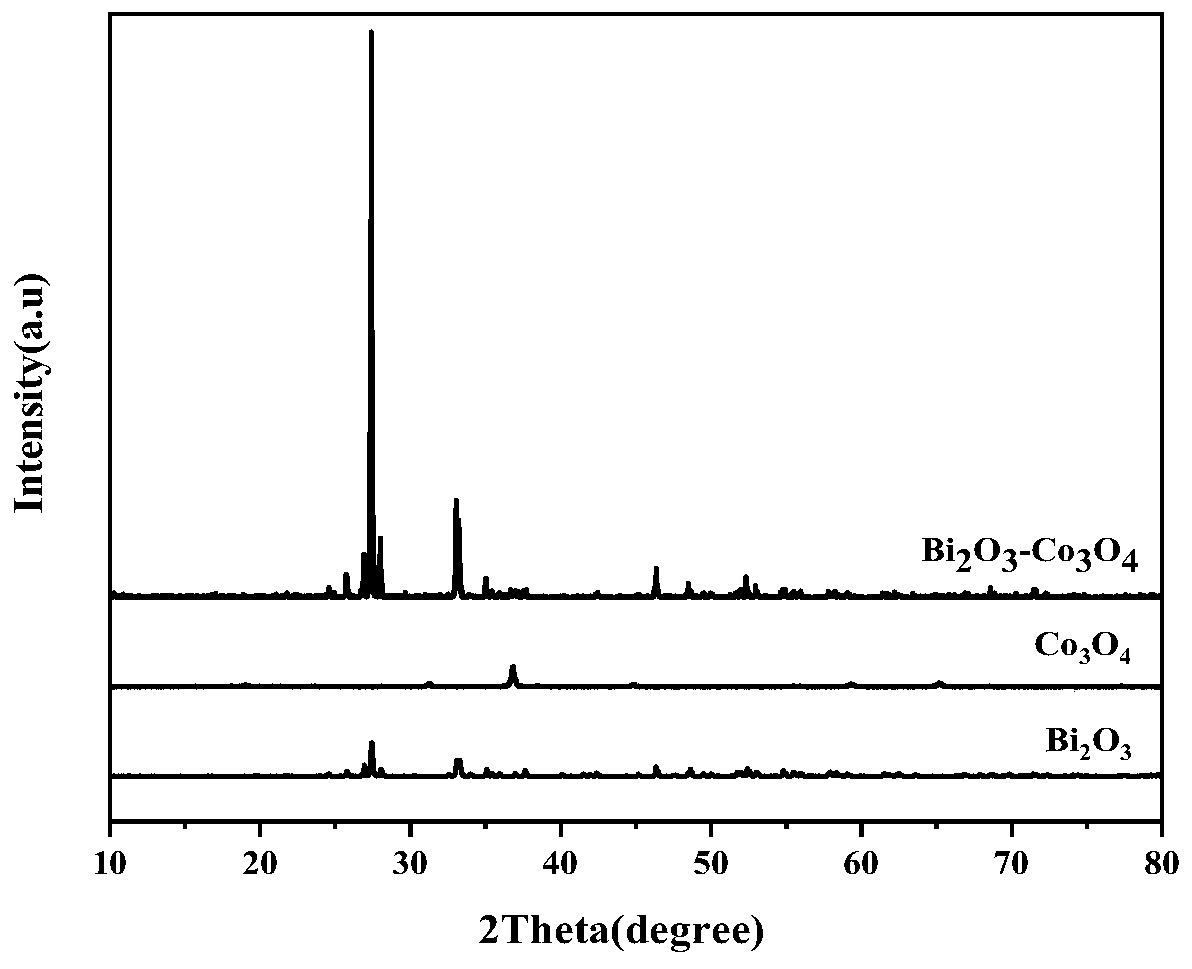

Preparation method and application of composite material Bi2O3-Co3O4 for degrading gaseous pollutants at room temperature

A technology of bi2o3-co3o4 and composite materials, applied in the direction of separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of air secondary pollution, high cost, inconvenient use, etc., and achieve easy reaction conditions, The effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Composite material Bi for degradation of gaseous pollutants at room temperature 2 o 3 -Co 3 o 4 preparation method

[0024] 1) Dissolve 1.94 g of cobalt nitrate hexahydrate and 1.94 g of bismuth nitrate pentahydrate in 15 mL of nitric acid, respectively, and then dilute to 50 mL respectively to obtain a solution containing bismuth and a solution containing cobalt.

[0025] 2) Mix the bismuth-containing solution and the cobalt-containing solution obtained in step 1) evenly, pour into the mixed solution of 3mL polyethylene glycol and 50mL NaOH solution with a concentration of 0.8mol / L, precipitate after stirring, and centrifuge , the obtained precipitate was washed twice with deionized water and once with ethanol, and the sample obtained after centrifugation was placed in a drying oven and dried at 100° C. for 10 h.

[0026] 3) The dried sample was calcined in a muffle furnace under air conditions at a heating rate of 5°C / min, 500°C for 2h, cooled to room temperat...

Embodiment 2

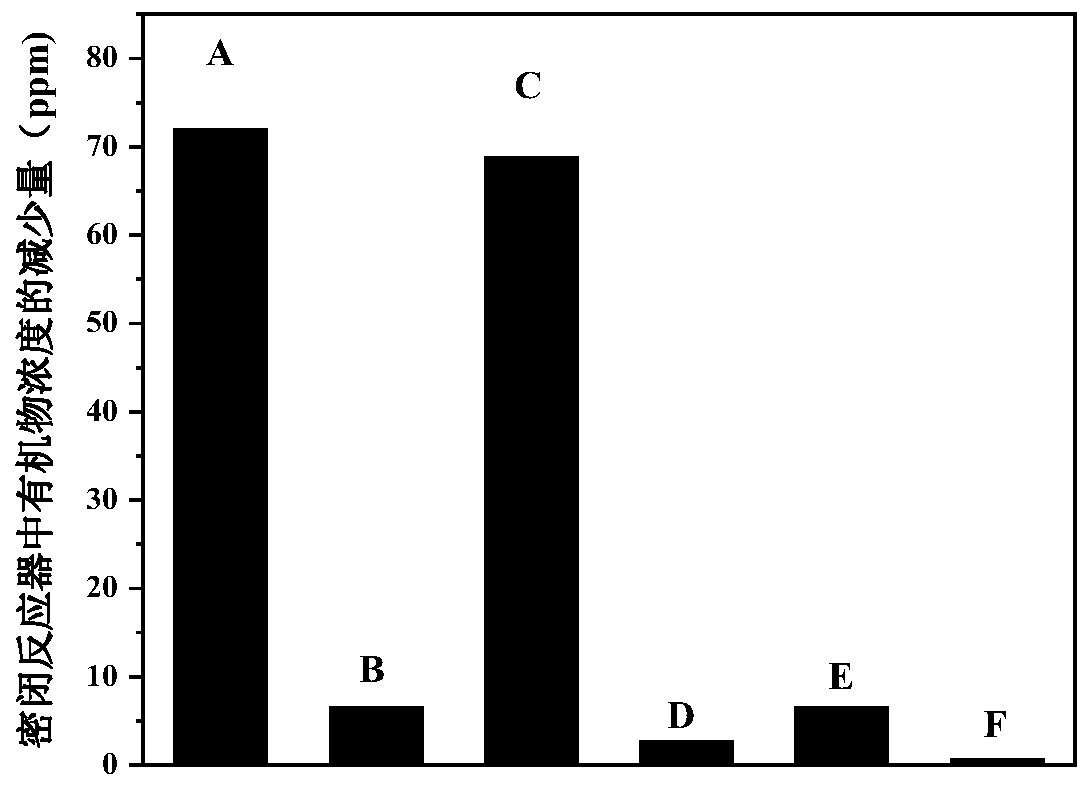

[0030] Composite Bi 2 o 3 -Co 3 o 4 Application as a catalyst in the degradation of gaseous pollutants at room temperature

[0031] (1) Degradation of formaldehyde

[0032] Method: get the composite material Bi prepared by 0.1 gram embodiment 1 2 o 3 -Co 3 o 4 Put it into a closed experimental device, inject 5 μL of 37% formaldehyde solution into the experimental device, and regularly detect the concentration of formaldehyde gas in the experimental device.

[0033] Comparative test: Inject 5 μL of 37% formaldehyde solution directly into the airtight experimental device, and regularly detect the concentration of formaldehyde gas in the experimental device.

[0034] After standing still at room temperature for 10 h, the concentration of formaldehyde gas in the experimental device was measured. Such as figure 2 as shown, figure 2 In A is the addition of composite material Bi 2 o 3 -Co 3 o 4 histogram of figure 2 In A, it can be seen that after 10 hours, the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com