Wheel hub vertical spinning machine

A technology of spinning machines and hubs, applied in the field of spinning machines, which can solve problems such as inconvenient transportation and installation, complicated mechanism structure, and large lateral size, and achieve the effects of low debugging cost, simplified mechanism, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

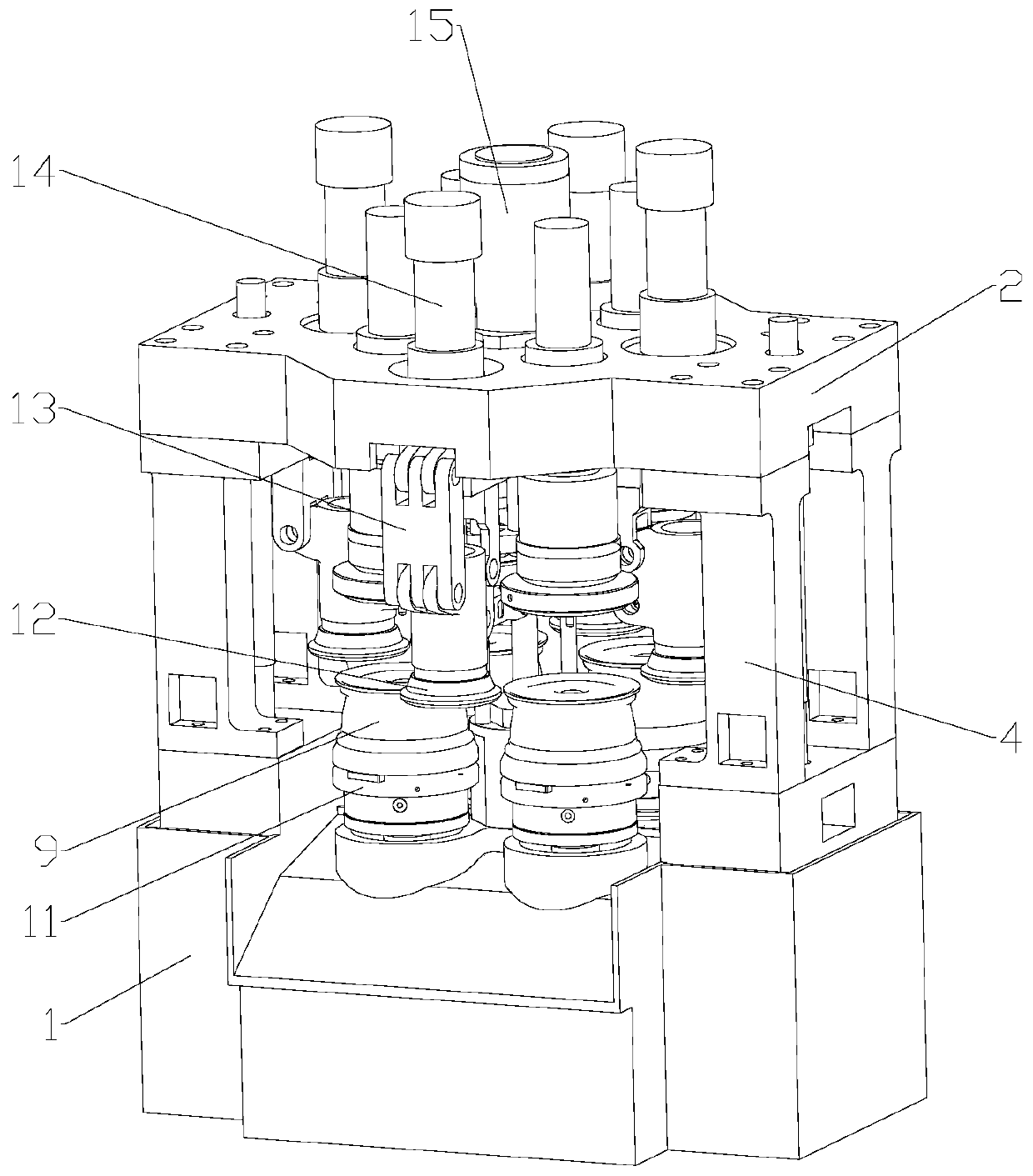

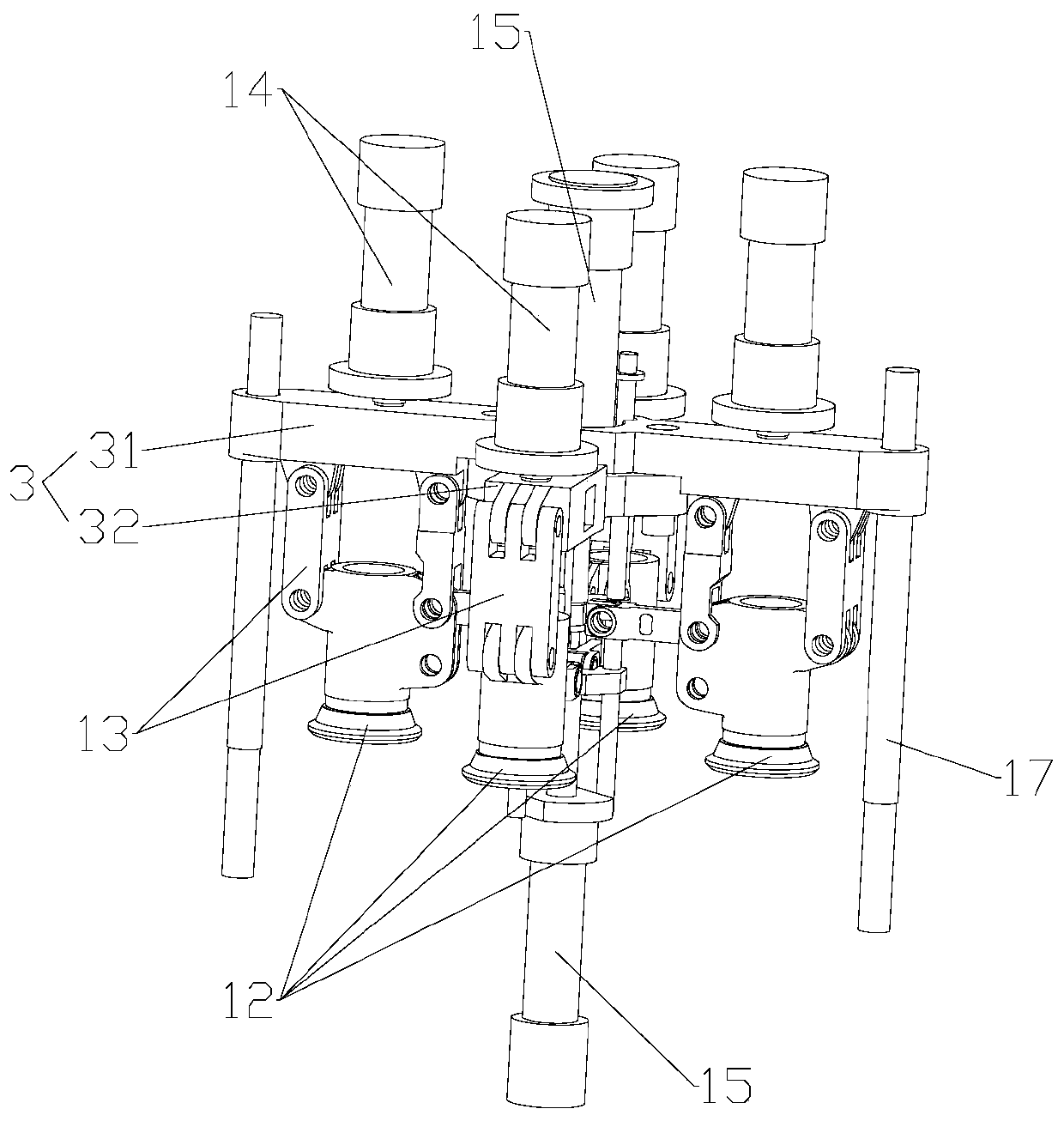

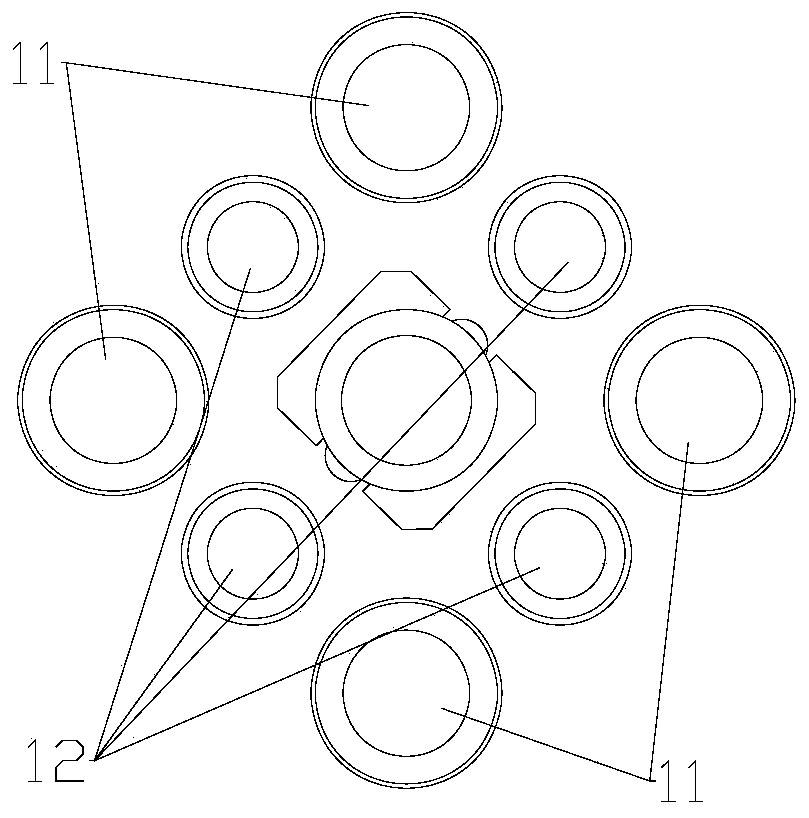

[0021] Such as figure 1 As shown, the present invention provides a hub vertical spinning machine, including a body 1, a spinning assembly and a feed assembly provided on the body 1, and the spinning assembly includes a main shaft 11 that drives the rotation of the hub 9 and a spinning hub 9 The spinning wheel 12, the feeding assembly includes a parallelogram linkage 13, a longitudinal feeding hydraulic cylinder 14 and a lateral feeding hydraulic cylinder 15, and the spinning wheel 12 is connected to the longitudinal feeding hydraulic cylinder 14 through a parallelogram linkage 13 The piston rod of the vertical feeding hydraulic cylinder 14 drives the spinning wheel 12 to lift up and down, and the piston rod of the horizontal feeding hydraulic cylinder 15 is connected and drives the spinning wheel 12 to approach or move away from the hub 9 laterally.

[0022] The present invention utilizes the parallelogram linkage mechanism 13 as the guiding structure for guiding the lateral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com