Electrochemical water treatment device

A water treatment device and electrochemical technology, applied in the field of electrochemistry, can solve the problems of small processing capacity, difficult engineering, and inability to enlarge the volume, and achieve the effects of solving hydraulic retention time, reducing energy consumption, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

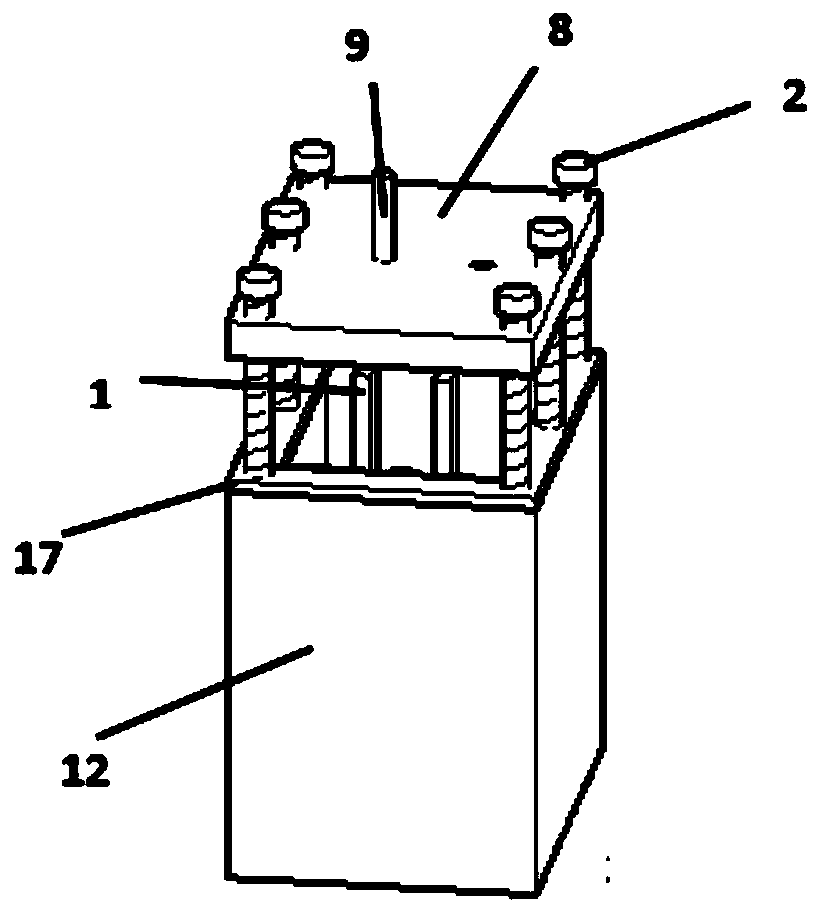

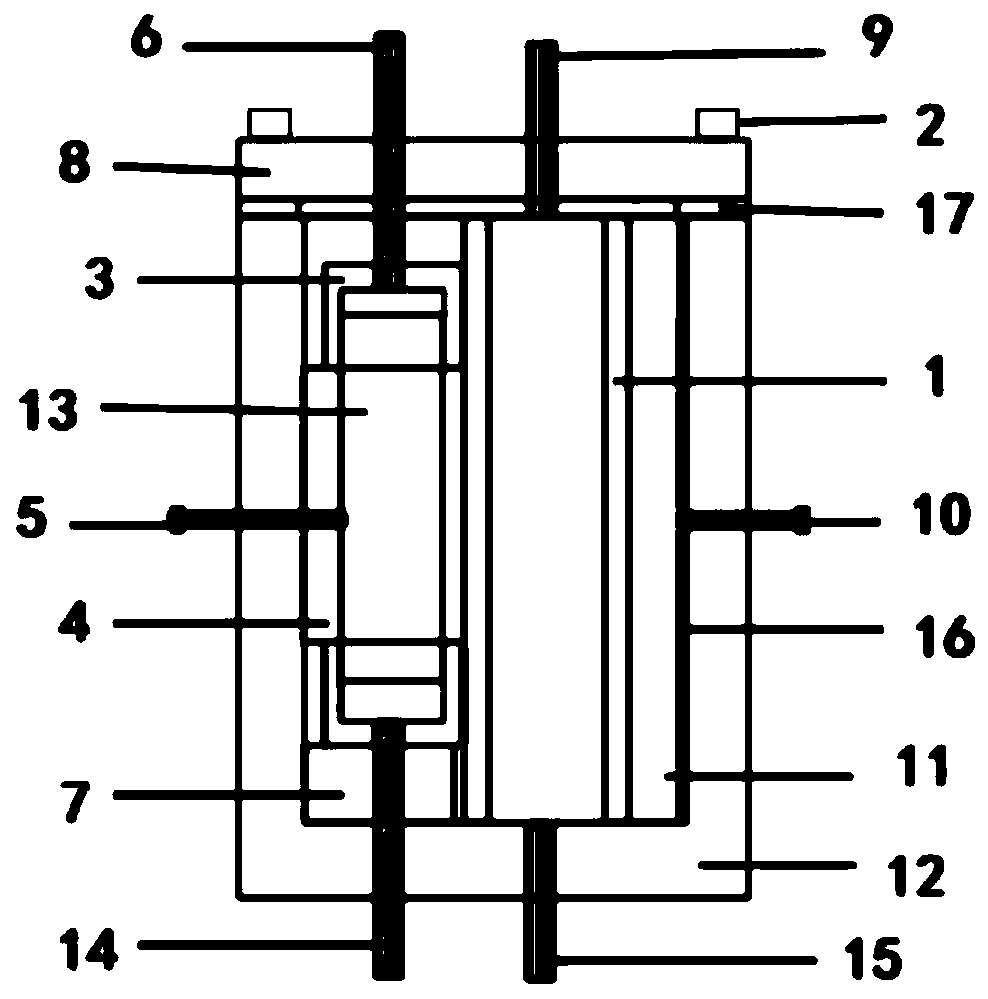

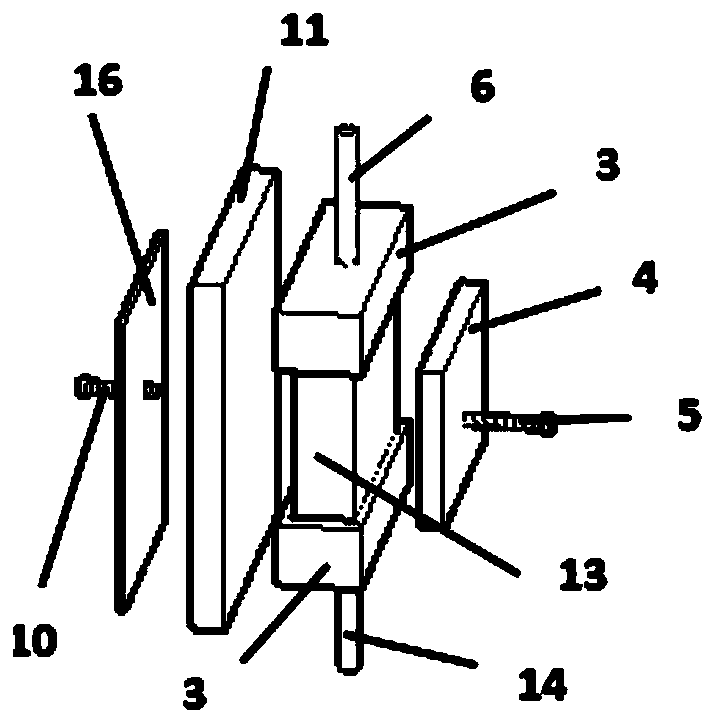

[0020] Such as figure 2 As shown, the electrochemical water treatment device based on the multi-level channel electrode 13 includes a baffle plate 1, a screw 2, a water collection and distribution groove 3, a multi-level channel electrode waterproof insulating pad 4, and a multi-level channel electrode terminal 5 , connecting pipe A6, bearing plate 7, device housing cover 8, connecting pipe B9, counter electrode terminal 10, counter electrode 11, device housing 12, multi-stage channel electrode 13, communicating tube C14, communicating tube D15, counter electrode waterproof insulation Pad 16 and gasket 17. First, install the baffle plate 1 and the load-bearing plate 7 to a suitable position. After tightly wrapping the two ends of the multi-stage channel electrode 13 with the water-collecting distribution groove 3, place it on the load-bearing plate 7 as a whole, and place the multi-stage channel electrode The waterproof insulating pad 4 is placed between the multi-level chan...

Embodiment 2

[0022] According to the connection mode connection device described in embodiment 1, water is taken in by the connecting pipe C14, and the water is discharged from the connecting pipe A6; the connecting pipe B9 and the connecting pipe D15 are sealed; the multi-stage channel electrode 13 is used as the anode, and the anode is Ti / TiO 2 Nanotube array electrode, Fe as the counter electrode 11, to realize the detection of Cu in sewage 2+ , Zn 2+ 、Ag + Degradation and removal of heavy metal ions.

Embodiment 3

[0024] According to the connection mode connection device described in embodiment 1, the water is fed into the connecting pipe C14, and the water is discharged from the connecting pipe A6; the connecting pipe B9 and the connecting pipe D15 are sealed; the multi-stage channel electrode 13 is used as an anode, and the anode is PbO 2 The electrode is made of stainless steel as the counter electrode 11 to realize the treatment of ammonia nitrogen wastewater and the removal of nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com