Energy-saving beer wastewater treatment equipment utilizing hydraulic flow disturbance

A technology of beer wastewater and hydraulic disturbance, which is applied in the fields of food industry wastewater treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., and can solve the problems of reduced wastewater treatment effect, poor wastewater treatment effect, and water environmental hazards, etc. , to achieve the effect of improving the wastewater treatment effect, avoiding the reduction of the wastewater treatment effect, and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

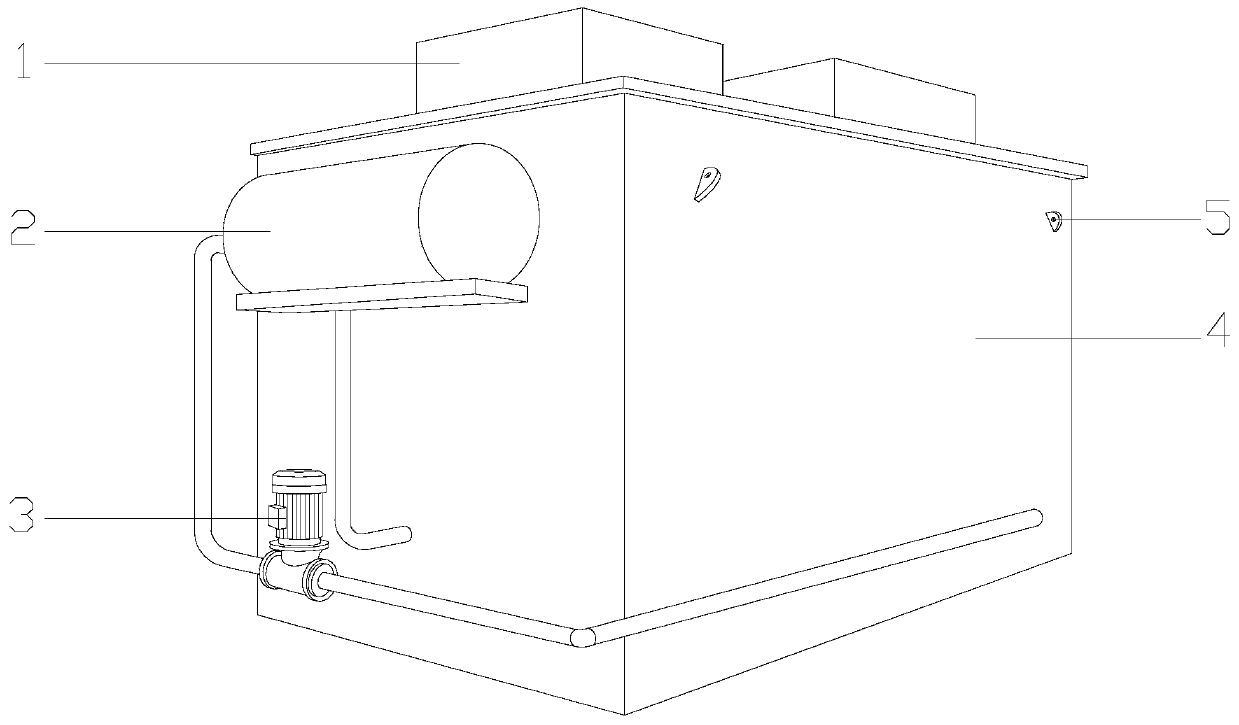

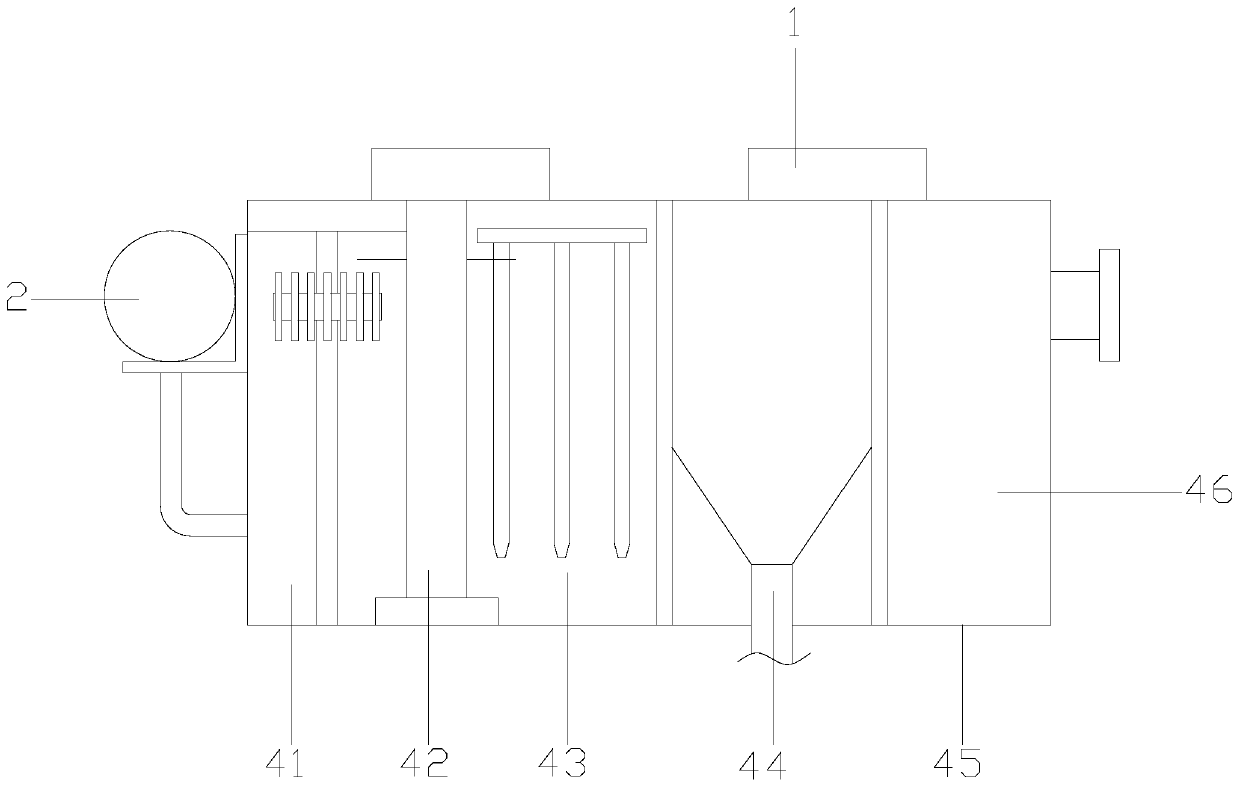

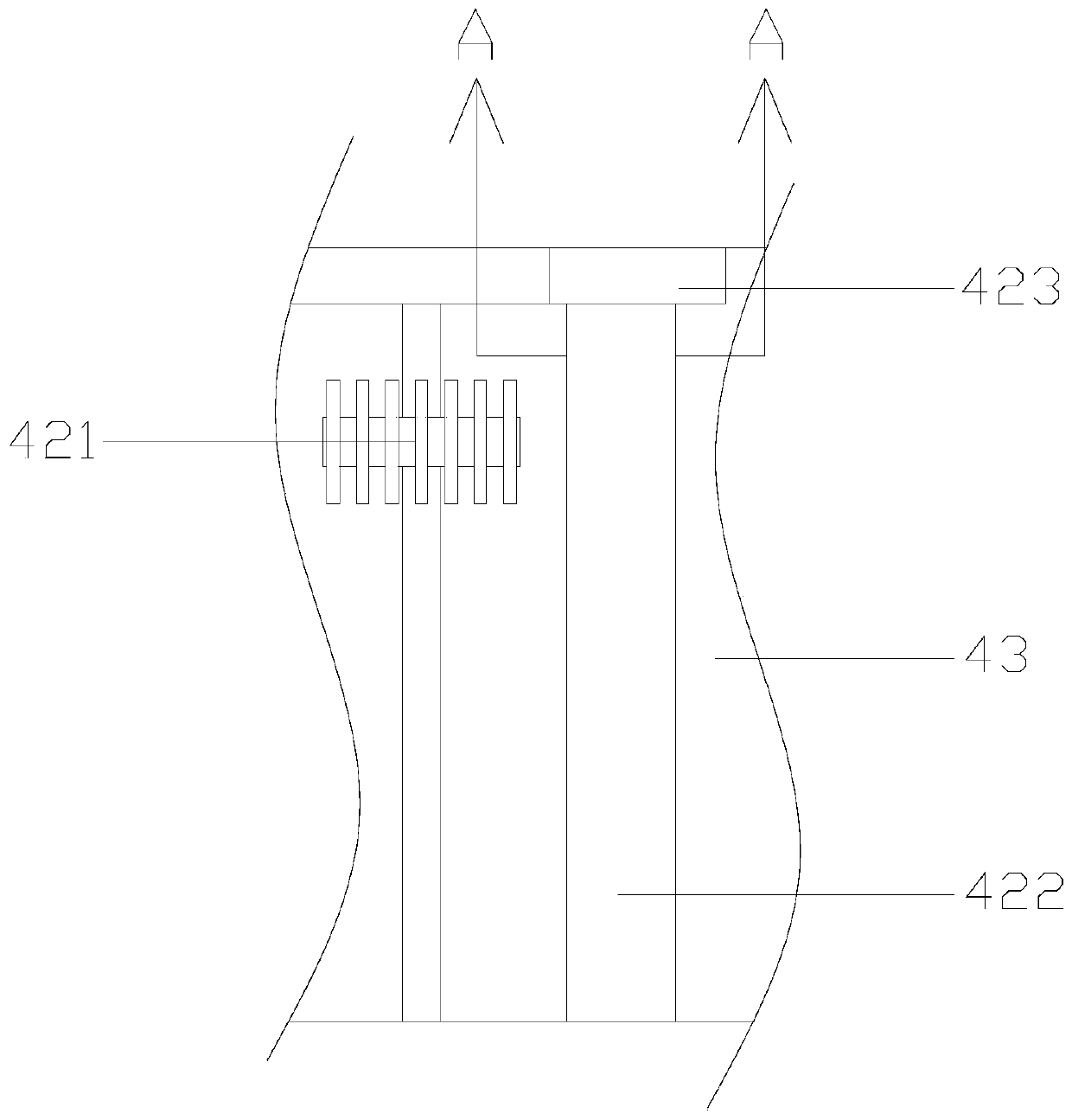

[0026] see Figure 1-Figure 2 , the present invention provides an energy-saving beer wastewater treatment equipment utilizing hydraulic disturbance, the structure of which includes an inspection port 1, a circulating tank body 2, a circulating water pump 3, an integrated processor 4, and a hook 5, the integrated processor 4 is a rectangular structure and is placed horizontally on the ground. Two hooks 5 are provided and welded to the right side surface of the integrated processor 4 respectively. The bottom of the inspection port 1 is connected to the upper surface of the integrated processor 4. Fastened together by bolts, the circulating water pump 3 is located at the lower left corner of the front of the integrated processor 4 and is sealed with the integrated processor 4, and the circulating tank 2 is located above the circulating water pump 3 and integrated with the circulating water pump 3 and The processors 4 communicate with each other, and the integrated processor 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com