Semi-red mud water permeable brick and preparation method thereof

A technology for permeable bricks and red mud, applied in clay products, other household appliances, applications, etc., can solve the problems of heavy metal dissolution irradiation coefficient, difficult to guarantee safety, limited consumption of red mud, etc., to achieve synergistic consumption, reduce The effect of reducing production cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

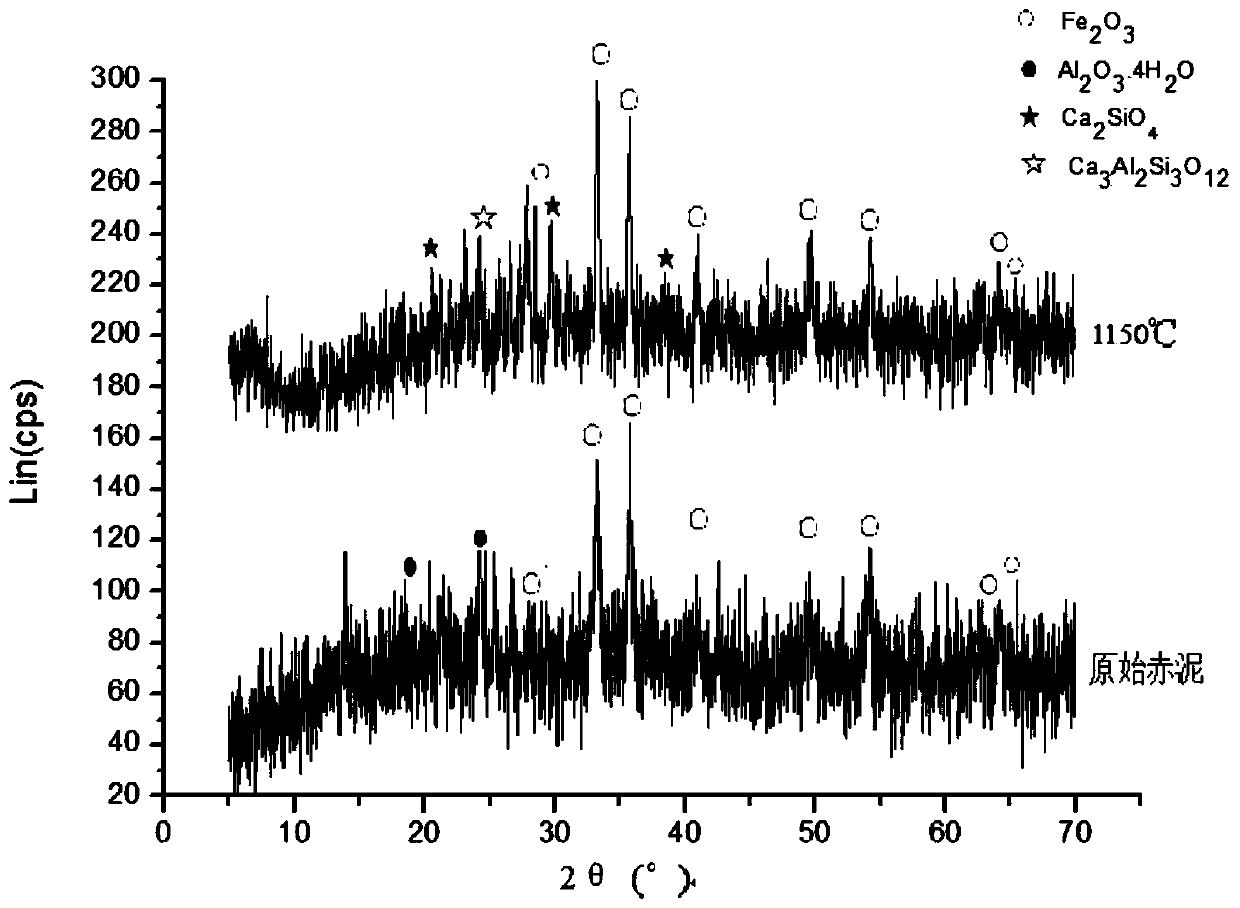

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a semi-red mud permeable brick, and its preparation raw materials include:

[0044] 45 parts of red mud, 8 parts of bentonite, 45 parts of waste ceramic particle aggregate, 6 parts of granite waste, and 7 parts of water glass solution.

[0045] The mass concentration of water glass solution is 25%; the particle size of granite waste is 325 mesh; the particle size of bentonite is 325 mesh.

[0046] This embodiment also provides a method for preparing semi-red mud permeable bricks, comprising the following steps:

[0047]Mix red mud, bentonite, waste ceramic granular aggregate, granite waste and water glass solution evenly to obtain a permeable brick mixture;

[0048] Fill the permeable brick mixture in the metal brick mold of the press, and pressurize it at 45MPa;

[0049] The pressed bricks are dried at 110°C for 9 hours, and then calcined at 1080°C for 1.5 hours to make semi-red mud permeable bricks.

[0050] The semi-red mud permeable brick...

Embodiment 2

[0083] This embodiment provides a semi-red mud permeable brick, and its preparation raw materials include:

[0084] 50 parts of red mud, 10 parts of Suzhou soil, 50 parts of waste high alumina refractory aggregate, 8 parts of feldspar, and 8 parts of silica sol solution.

[0085] The mass concentration of silica sol solution is 20%; the particle size of feldspar is 325 mesh; the particle size of Suzhou soil is 325 mesh.

[0086] This embodiment also provides a method for preparing semi-red mud permeable bricks, comprising the following steps:

[0087] Mix red mud, Suzhou soil, waste high alumina refractory aggregate, feldspar and silica sol solution evenly to obtain a permeable brick mixture;

[0088] Fill the permeable brick mixture in the metal brick mold of the press, and pressurize it at 60MPa;

[0089] The pressed bricks are dried at 120°C for 10 hours, and then calcined at 980°C for 2 hours to make semi-red mud permeable bricks.

[0090] The semi-red mud permeable bri...

Embodiment 3

[0094] This embodiment provides a semi-red mud permeable brick, and its preparation raw materials include:

[0095] 40 parts of red mud, 5 parts of silicon-aluminum additives, 45 parts of ceramic tailings aggregate, 5 parts of granite waste, and 5 parts of water glass solution.

[0096] The above-mentioned silicon-aluminum additives all include 80% by weight of plastic clay, 20% by weight of waste glass powder, and the particle size is 325 mesh.

[0097] The mass concentration of water glass solution is 30%.

[0098] Granite waste with a particle size of 325 mesh.

[0099] This embodiment also provides a method for preparing semi-red mud permeable bricks, comprising the following steps:

[0100] Mix red mud, silicon-aluminum additives, ceramic tailings aggregate, granite waste and water glass solution evenly to obtain a permeable brick mixture;

[0101] Fill the permeable brick mixture in the metal brick mold of the press, and pressurize it at 30MPa;

[0102] The pressed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com