Conical refiner with mechanical and hydraulic linkage for adjusting tool feeding and retracting and refining pulp specific pressure

A conical grinding and knife retracting technology, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of high energy consumption and single applicability, and achieve less friction loss and wide application range , Timely maintenance and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

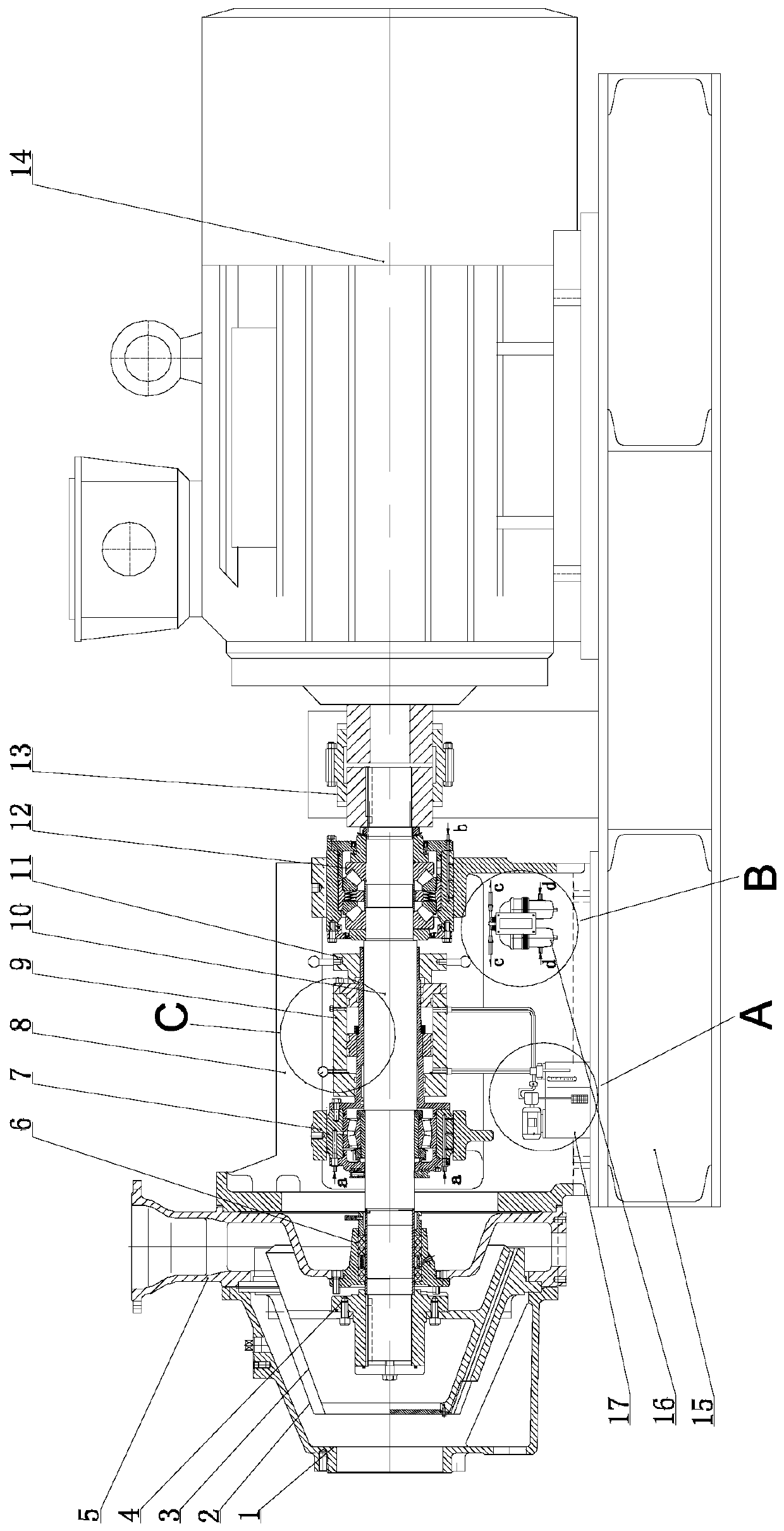

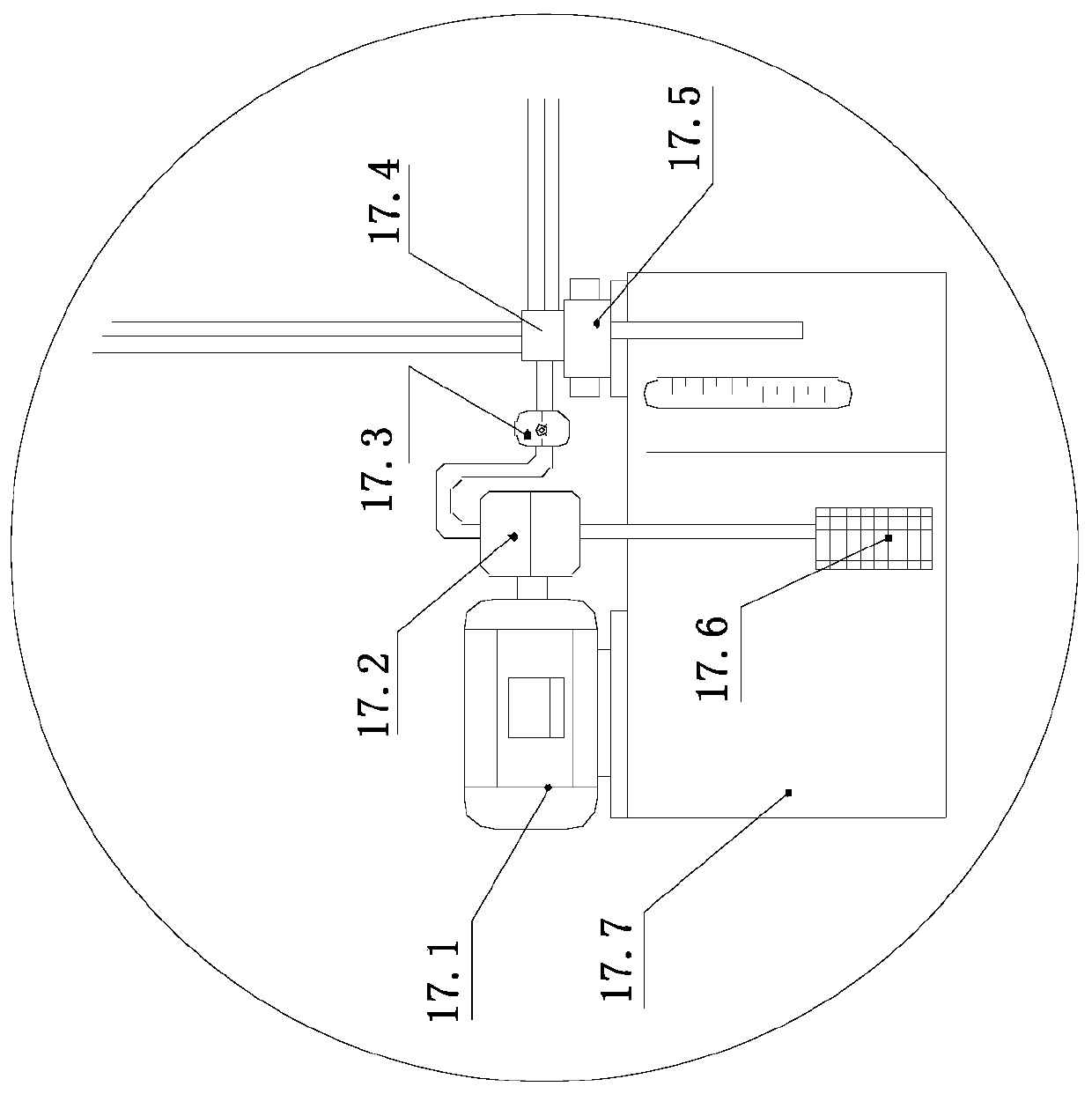

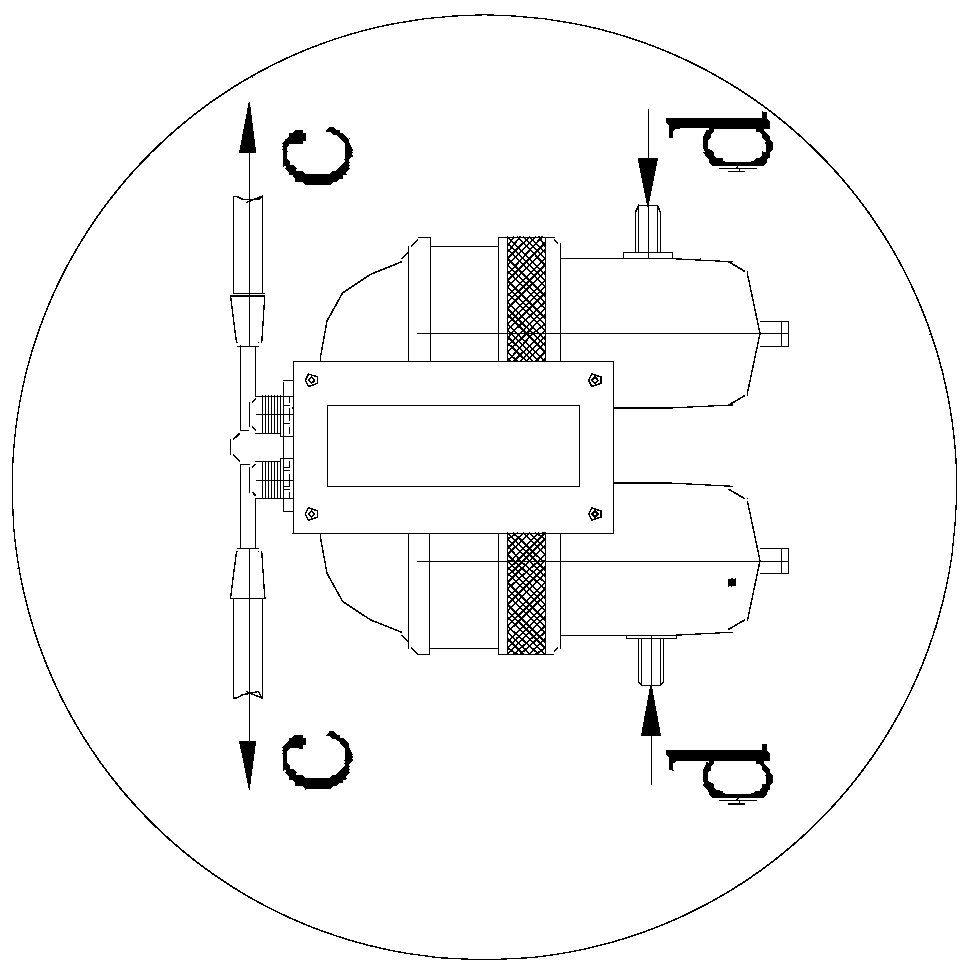

[0034] Such as figure 1 As shown, a conical refiner capable of adjusting the feed and retreat and the specific pressure of the refining by the linkage of the machine and the fluid includes a conical refiner body and a linkage adjustment unit 17 of the machine and fluid.

[0035] The conical refiner itself includes a base 15, a main shaft 10, a conical refining main body which is sequentially fixed on the base 15, a bearing housing 8 and a main motor 14. The rear end of the main shaft 10 passes through the shaft The forward displacement coupling is drivingly connected to the main motor 14, the middle part is fixedly connected to the bearing inner rings of the front bearing body assembly 7 and the rear bearing body assembly 12 arranged at intervals, and the front end of the main shaft 10 is driven by the conical refining body Connected, the outer peripheral walls of the front bearing body assembly 7 and the rear bearing body assembly 12 are in sliding fit with the corresponding moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com