Tight reservoir millimeter-level sample oil source direct analysis and comparison method

A tight reservoir, millimeter-scale technology, applied to the analysis of materials, material separation, measurement devices, etc., can solve the problems of unclear source of crude oil and oiliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

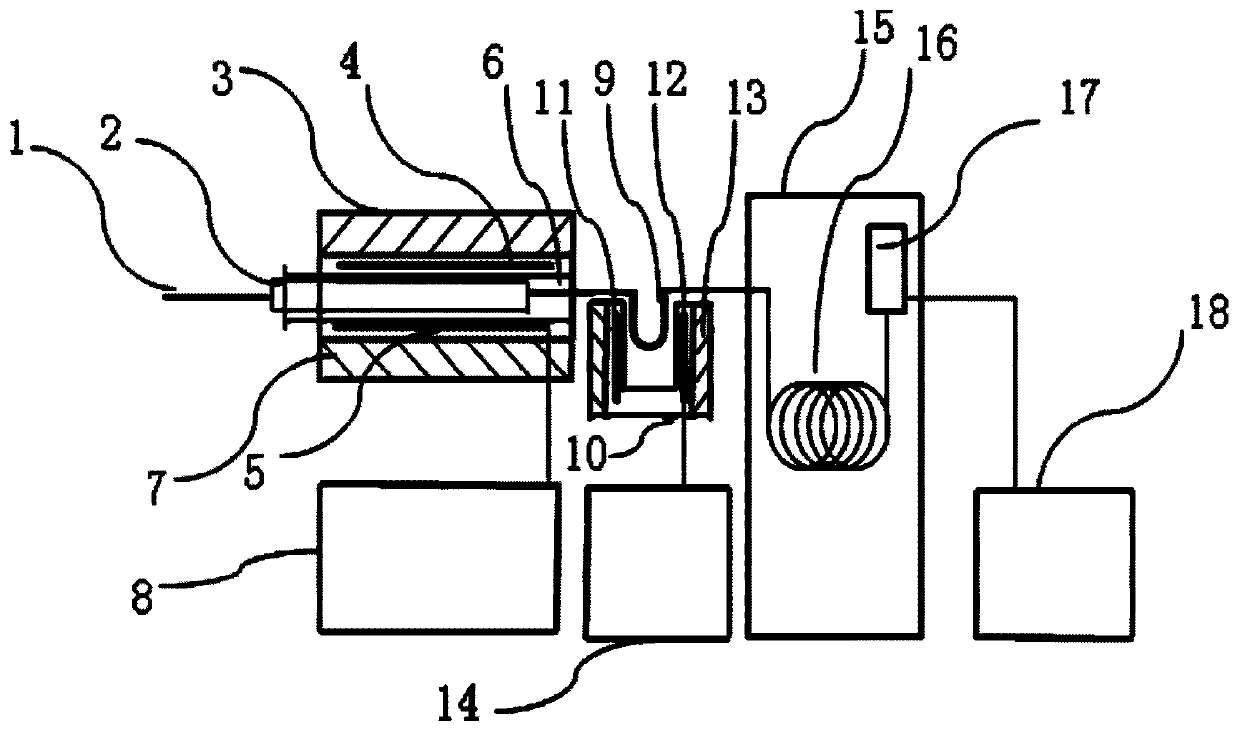

Method used

Image

Examples

specific Embodiment

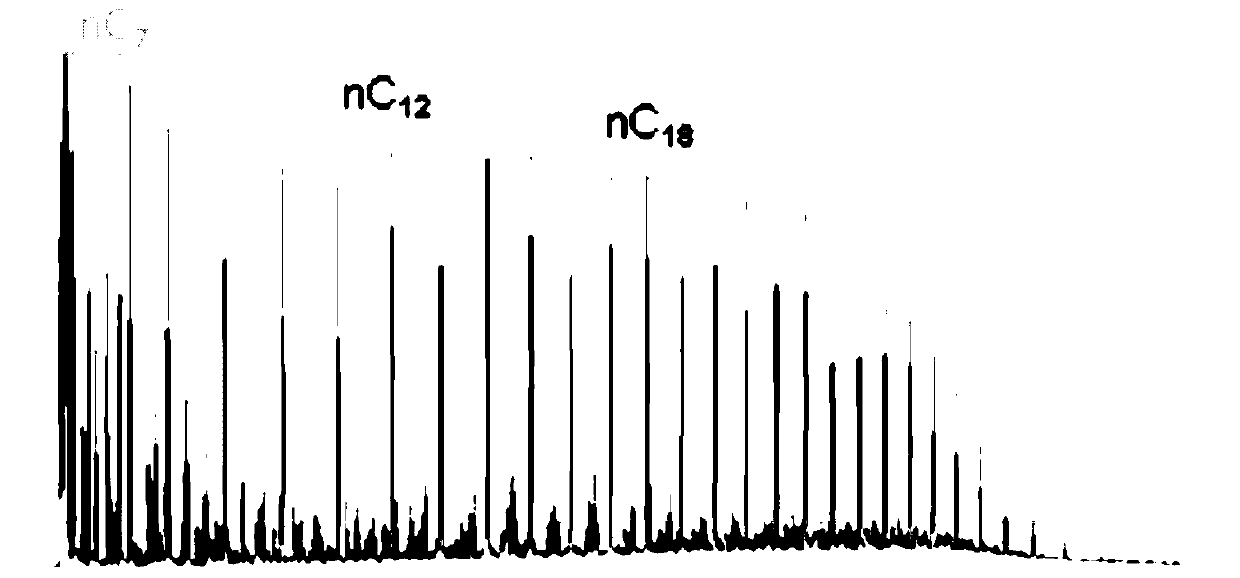

[0052] The implementation process of the method of the present invention is illustrated by taking tight oil prospecting well Qp1 in the Daqing exploration area as an example.

[0053] Well Qp1 is a pre-exploration well for medium-shallow tight oil in the Daqing exploration area. It is located in the Xingxi nose structure of the Qijia Sag in the central depression of the Songliao Basin. The formations encountered are Quaternary, Tertiary Taikang Formation, Upper Cretaceous Mingshui Formation, Sifangtai Formation, Lower Cretaceous Nenjiangzu, Yaojia Formation and Qingshankou Formation. Large-scale volumetric fracturing was used in Qing 2 and 3 Members of Qingshankou Formation, and a daily production of 10.2 tons of industrial oil flow was obtained, showing a good prospect for tight oil exploration in the Gaotaizi source in the northern Songliao Basin. In order to further study the formation mechanism and oiliness of unconventional tight oil and shale oil, based on the fine and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com