Method for predicting mass change of ceramic-based composite material in stress oxidation environment

A composite material, quality change technology, used in design optimization/simulation, special data processing applications, instruments, etc., can solve the problem that the analysis of unidirectional SiC/SiC material quality change does not consider the combined effect of stress and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] Below in conjunction with embodiment the present invention will be further described.

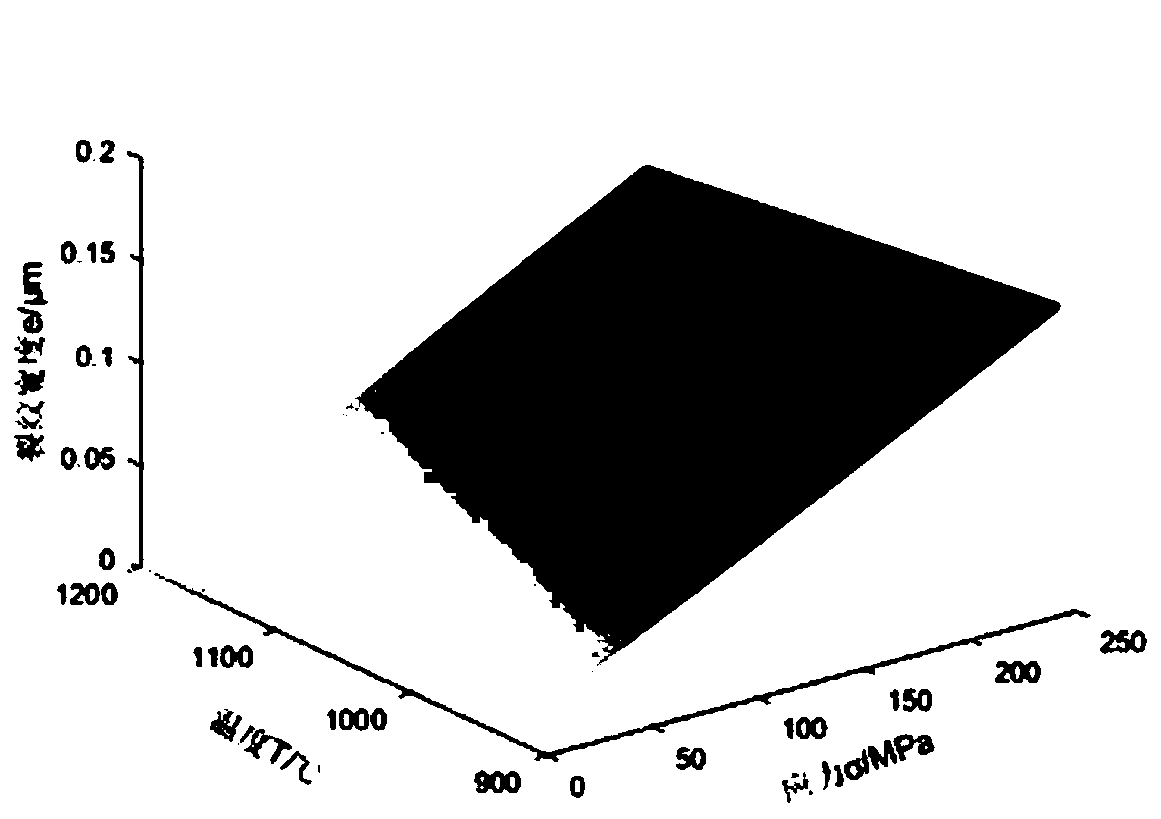

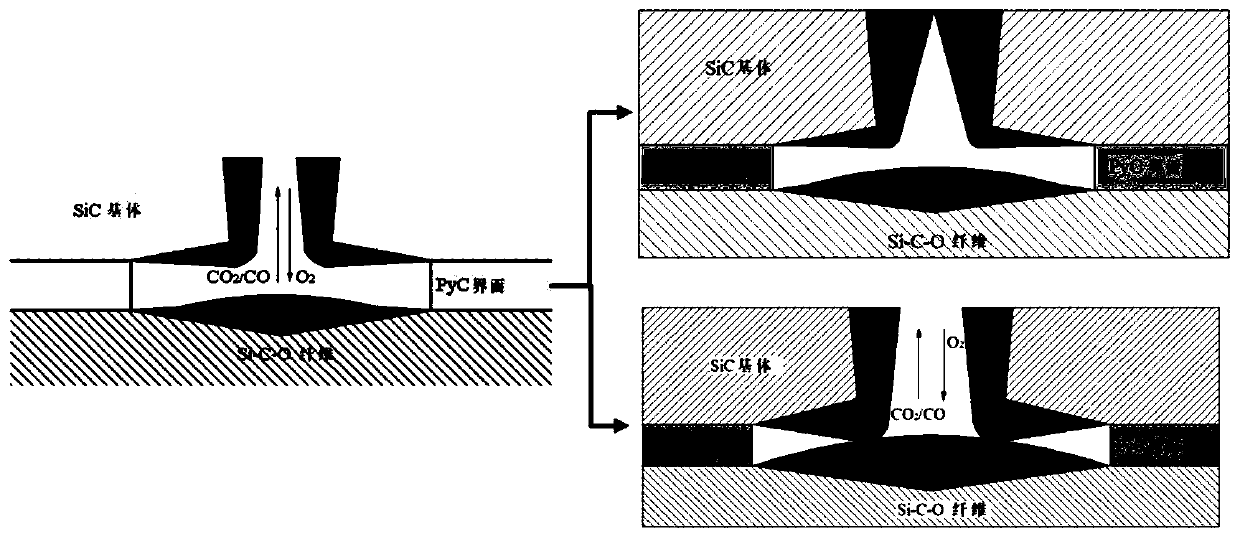

[0127] The method of the present invention predicts the quality change of the unidirectional SiC / SiC composite material under the stress oxidation environment (900-1200 ℃) for further explanation:

[0128] In the specific implementation steps, the environment is a pure oxygen environment, and the SiC fiber adopts the Nicalon series of Nippon Carbon Company, and its material parameters are shown in Table 1:

[0129] Table 1 Nicalon series fiber parameters

[0130]

[0131]

[0132] In this embodiment, the SiC fiber of the Nicalon model (the first column of Table 1) is selected, and its elemental composition is considered, expressed as Si x C y o z (x:y:z=1; 1.35; 0.375).

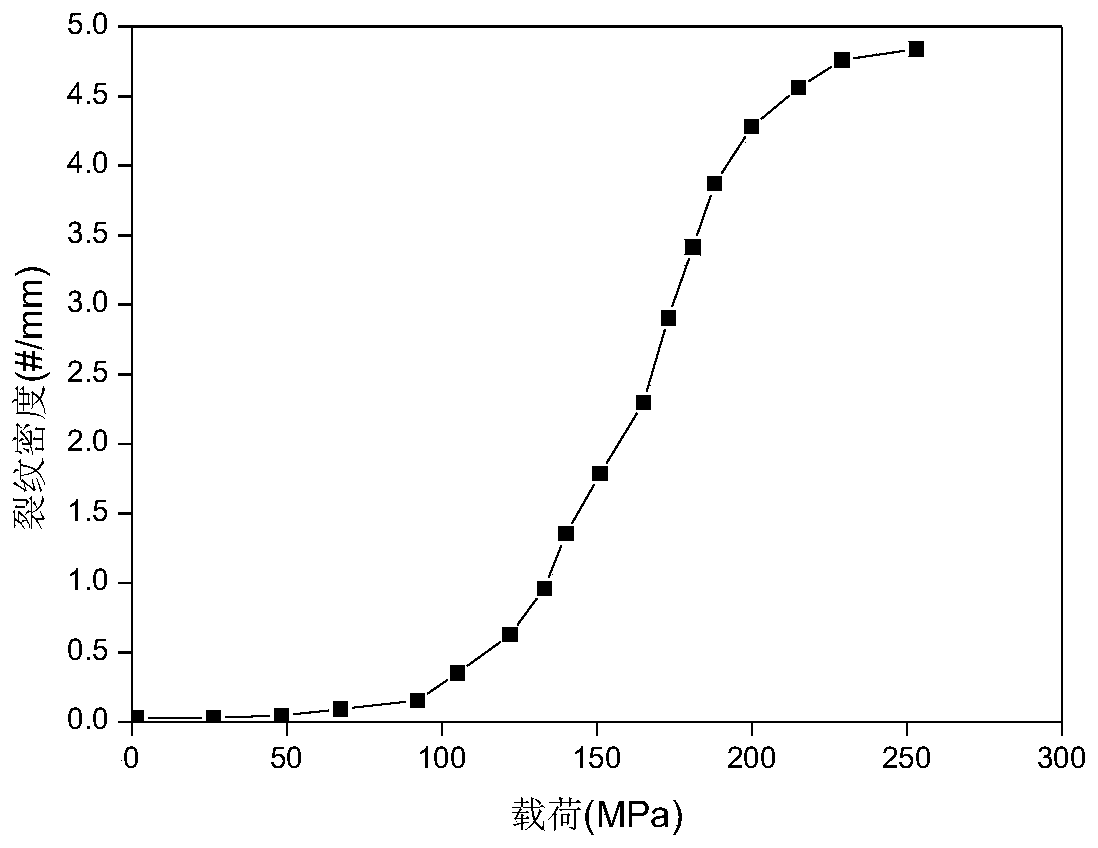

[0133] Step 1: Determine the change law of the number of matrix cracks in the material under stress and high temperature;

[0134] According to the Monte Carlo method, assuming that the failure probabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com