Quantified marinated and steamed spiced beef and making method thereof

A technology of quantitative marinating and production methods, which is applied in food heat treatment, food ingredients containing inorganic compounds, climate change adaptation, etc., can solve the problems of the loss of nutrient components of beef sauce, low yield of production methods, and easy danger to human health, etc., and achieves improvement. Taste effect, retain flavor, reduce the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Raw meat pretreatment:

[0041] Select 500g of fresh beef tendon meat after deacidification by weight, remove fat oil, congestion and fascia, wash and drain the water for later use;

[0042] (2) Cooking simulated old soup:

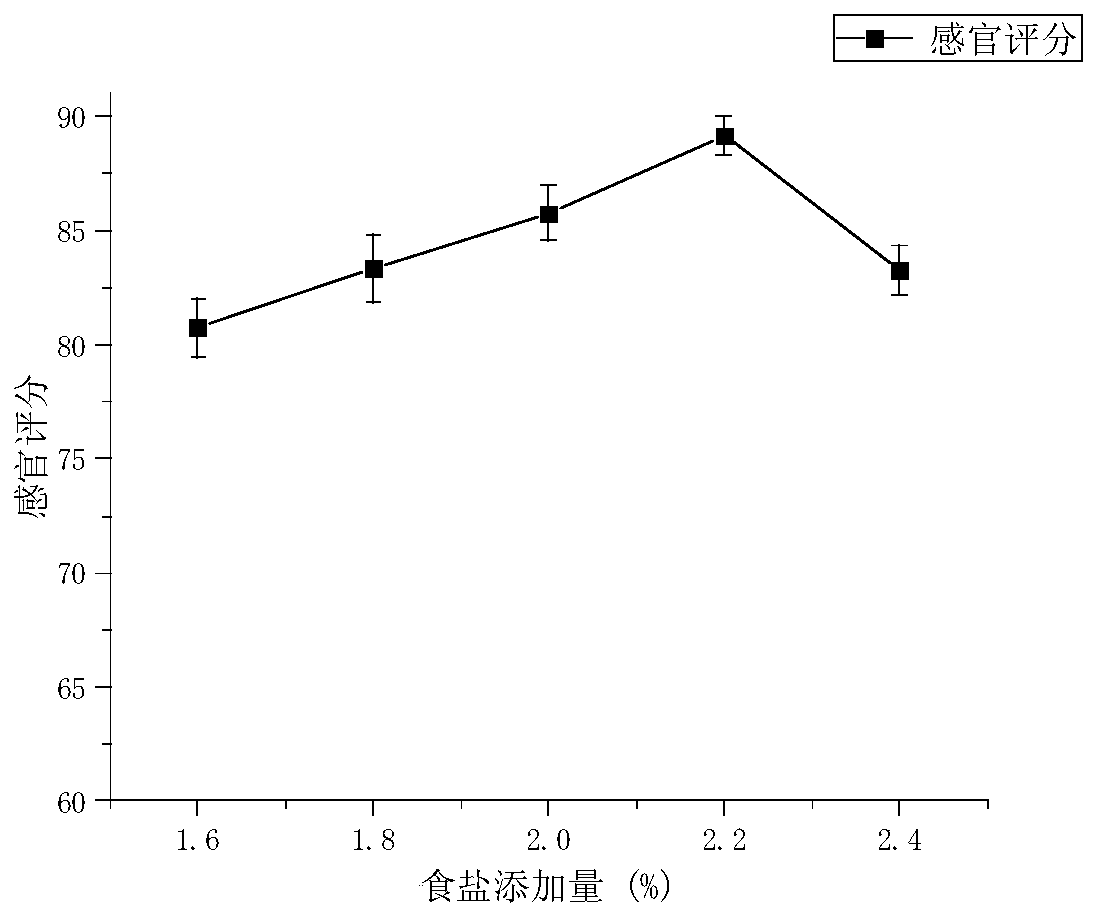

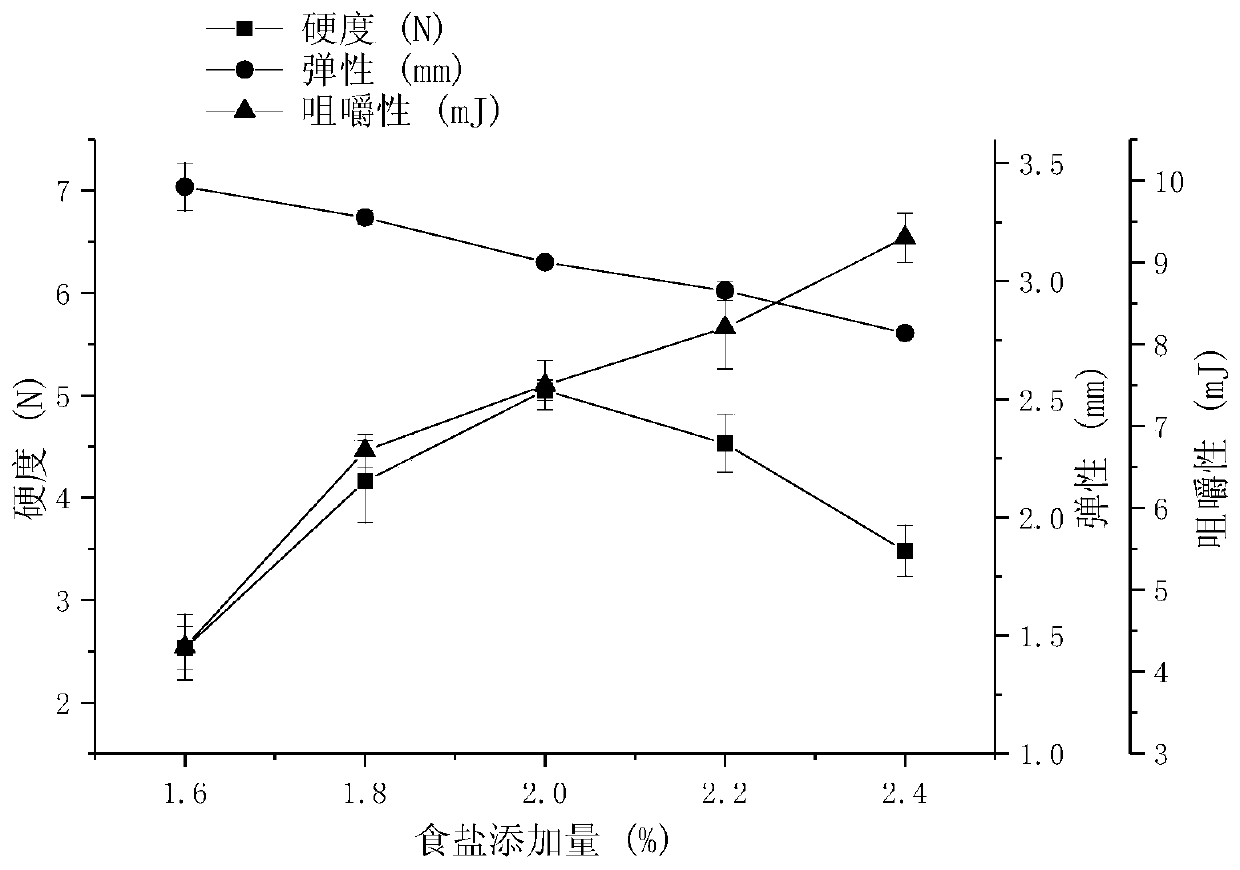

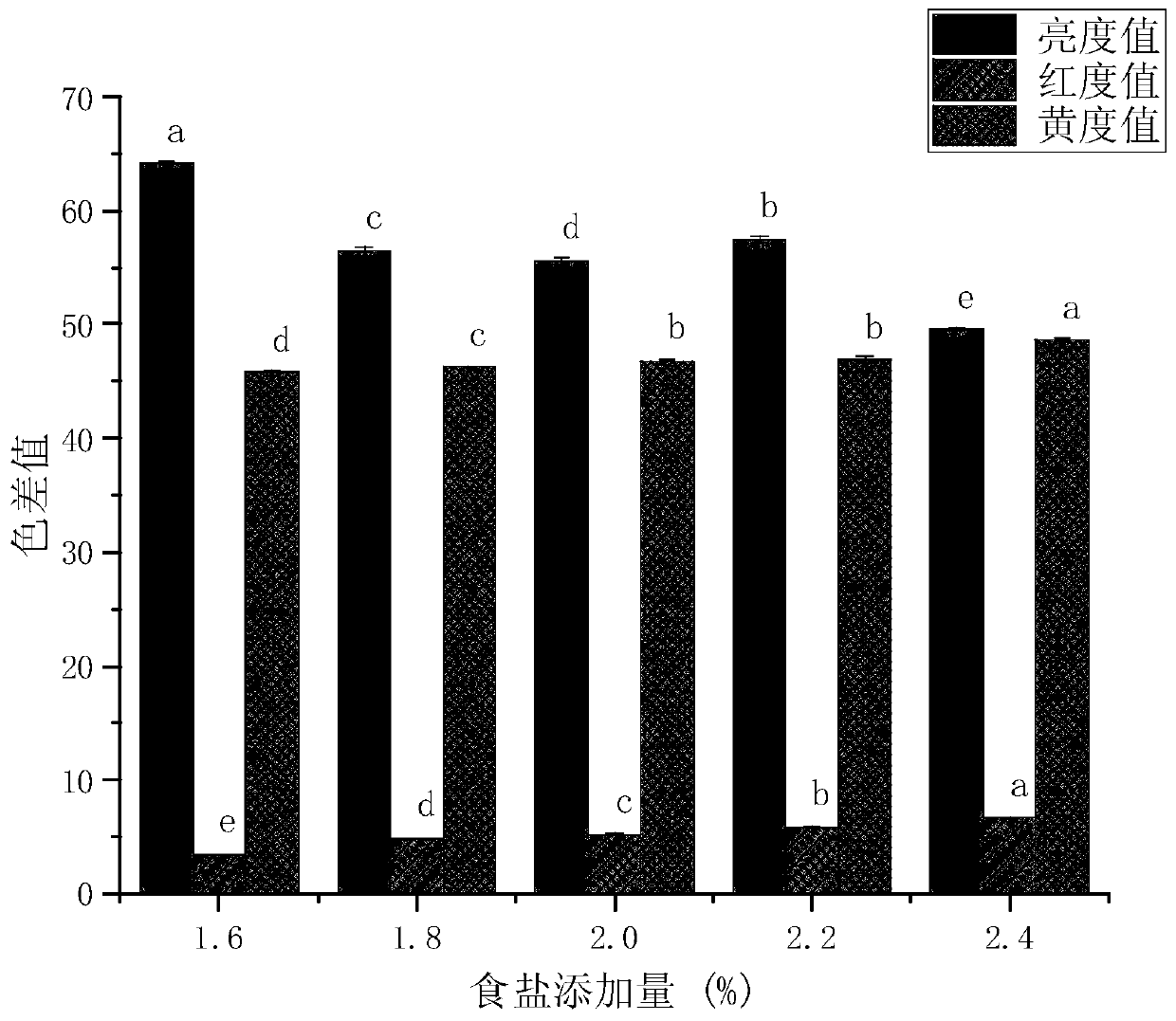

[0043] Stir-fry the compound spices and beef fat. The ingredients of the compound spices are: 0.9g of cloves, 3g of cinnamon bark, 3.75g of Chinese prickly ash, 9g of star anise, 1.8g of cumin, 7.5g of licorice, 3g of grass fruit, 2.25g of tangerine peel, 7.5g pepper and 45g ginger, fry with 50g beef fat to mature, add 1500g water, 4.5g white pepper powder, 1.5g thirteen spices, 15g white sugar, 45g soy sauce, 36g cooking wine, 6g monosodium glutamate, beef Essence 4.5g, salt 33g (accounting for 2.2% of the weight of the old soup), 4.5g of compound phosphate (accounting for 0.3% of the weight of the old soup), boil for 1 hour, then fully filter the water with a sieve, and filter out Impurities in feed water should be cooled for later use;

[...

Embodiment 2

[0056] (1) Raw meat pretreatment:

[0057] Select 600g of fresh beef tendon meat after deacidification by weight, remove fat oil, congestion and fascia, wash and drain, and cut into pieces evenly for later use, each piece is less than 500g;

[0058] (2) Cooking simulated old soup:

[0059] Stir-fry the compound spices and beef fat. The composition of the compound spices is: take cloves 1.1g, cinnamon bark 3.6g, pepper 4.5g, star anise 10.8g, cumin 2.2g, licorice 9g, grass fruit 3.6g, tangerine peel 2.7g by weight. g, 9g of pepper and 54g of ginger, after frying with 60g of beef fat to mature, add 1800g of water, 5.4g of white pepper powder, 1.8g of thirteen spices, 18g of white sugar, 54g of soy sauce, 45g of cooking wine, and 7.2g of monosodium glutamate , 5.4g of beef essence, 39.6g of salt (accounting for 2.2% of the weight of the old soup), 5.4g of compound phosphate (accounting for 0.3% of the weight of the old soup), boil for 1 hour, and then fully filter the water with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic value | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com