Brazing method

A brazing method and brazing technology, applied in the field of brazing and brazing in the electronics industry, can solve problems such as the inability to accurately control the amount of flux, and restrict the quality and efficiency of brazing production, so as to improve the quality and efficiency of spraying, Improve assembly efficiency and reduce physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

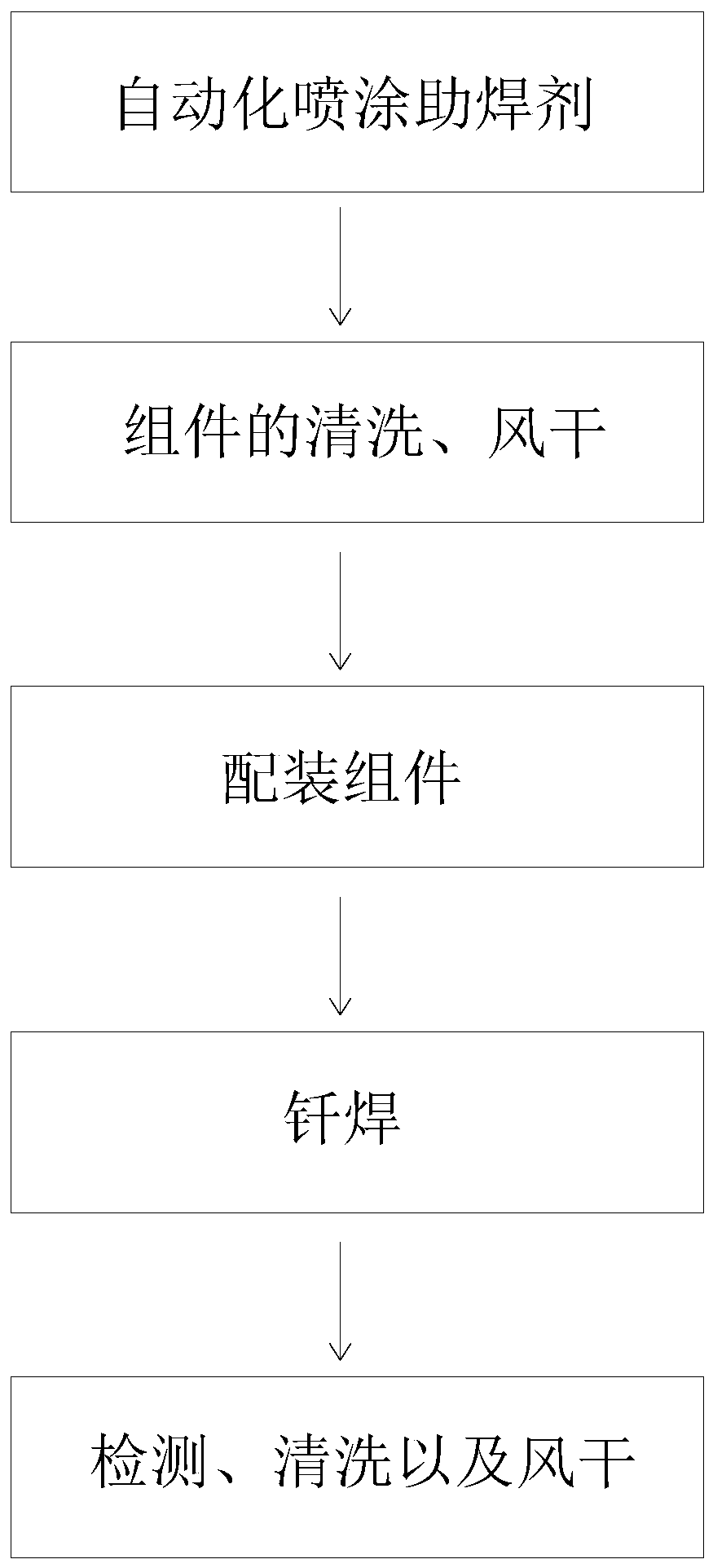

[0037] refer to figure 1 , the present embodiment discloses a brazing method, comprising the steps of:

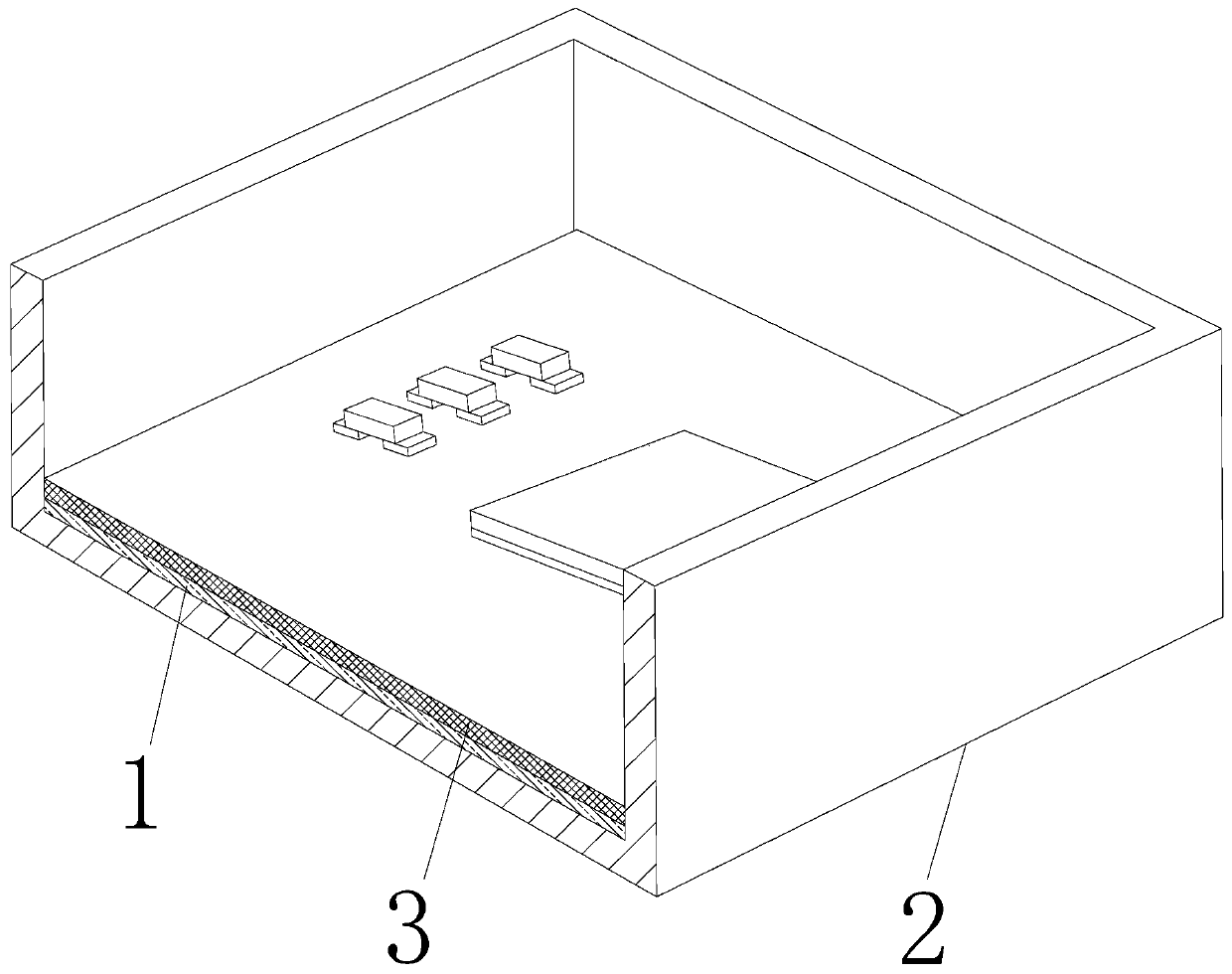

[0038] Step 1: Automatically spray flux to form pre-coated solder pads 1

[0039] Pre-spray halogen-free RMA or ROLO flux on the surface of the soldering piece by any of the spraying methods of automatic ultrasonic atomization spraying, air knife blowing or liquid constant flow spraying. Brazing workers do not need to touch liquid flux. Little damage.

[0040] Its principle is that during brazing, rosin and solder and oxides on the surface of the substrate (such as SnO and Cu 2 O etc.) the following reactions occurred:

[0041] 2C 19 h 29 COOH+SnO→Sn(C 19 h 29 COOH) 2 +H 2 O (1)

[0042] 2C 19 h 29 COOH+Cu 2 O→2CuCOOC 19 h 29 +H 2 O (2)

[0043] Since the surface to be welded of the deep cavity shell 2 and the circuit board 3 is gold-plated or silver-plated, the surface to be welded of the deep cavity shell 2 and the circuit board 3 has no oxidation, so it ...

Embodiment 2

[0057] Referring to this embodiment discloses a brazing method, comprising the following steps:

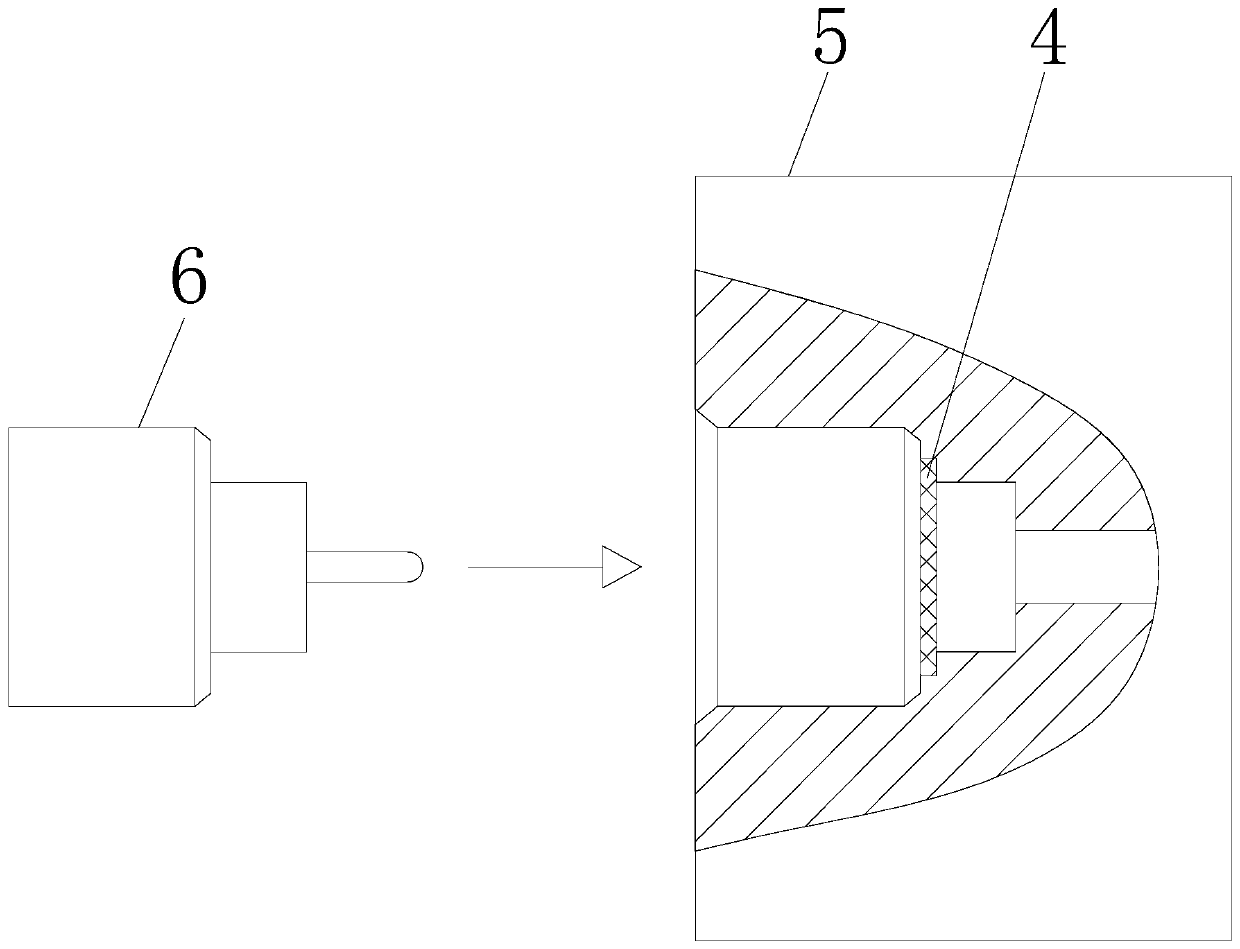

[0058] Step 1: Automated spraying of flux to form a pre-coated solder ring 4

[0059] The surface of the welding ring is pre-sprayed with halogen-free RMA or ROLO flux by any of the spraying methods of automatic ultrasonic atomization spraying, air knife blowing or liquid constant flow spraying. Brazing workers do not need to touch liquid flux. Little damage.

[0060] Its principle is that during brazing, rosin and solder and oxides on the surface of the substrate (such as SnO and Cu 2 O etc.) the following reactions occurred:

[0061] 2C 19 h 29 COOH+SnO→Sn(C 19 h 29 COOH) 2 +H 2 O (1)

[0062] 2C 19 h 29 COOH+Cu 2 O→2CuCOOC 19 h 29 +H 2 O (2)

[0063] Since the surfaces to be welded of the housing 5 and the connector 6 are gold-plated or silver-plated, the surfaces to be welded of the housing 5 and the connector 6 are free from oxidation, so it is not necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com