Rear steering engine lining machining technology

A processing technology and rear steering technology, which is applied in the field of auto parts manufacturing, can solve the problems that the processing technology of the front body connection bushing is not applicable, and achieve the effect of stable product size, mature technology, simple and reasonable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

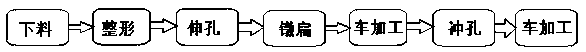

[0027] see figure 1 , a more economical bushing processing technology in this embodiment, which combines cold extrusion and mechanical processing, and the simple process is as follows:

[0028] (1) Cutting: the raw material is wire rod, φ20.8mm is suitable for cutting by cold heading machine; the production efficiency is high.

[0029] (2) Shaping: The material is directly shaped by the cold heading machine. Since the cold heading blanking material is not flat, the shaping is to prepare for the hole stretching sequence.

[0030] (3) Hole extension: specific punching die structure, reverse extrusion shaping blank, finished product is like a tube, due to pre-order shaping, inner and outer coaxialit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com