Synthesis method of MnO2 loaded 3-polyalkylthiophene

A technology of alkylthiophene and synthesis method, which is applied in the field of material chemistry to achieve the effect of stable structure and morphology control and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

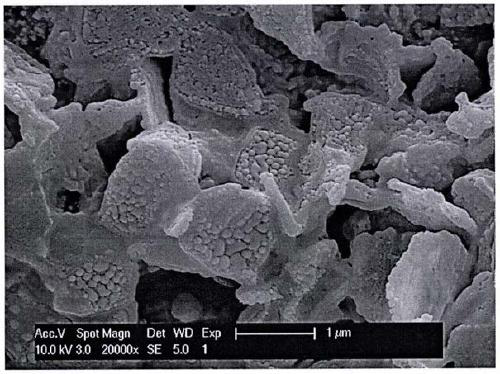

Embodiment 1

[0012] Add 0.1mol / L 3-methylthiophene monomer into 50mL deionized water, add 20gL -1 KI and 2gL -1 MnI 2 , ultrasonically stirred to form an emulsion; 50mL 1.6mol / L ferric chloride aqueous solution was slowly added to the first solution, stirring was continued during the addition process, and a precipitate was obtained after standing at room temperature for 12 hours, filtered, washed and dried to obtain the following: figure 1 MnO shown 2 Loaded poly-3-alkylthiophene powder. Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When the electrolyte on the two electrodes is in a semi-dry state, paste the two electrodes face to face, and dry to obtain a full solid state. Symmetrical supercapacitor with a specific capacity of 431Fg -1 .

Embodiment 2

[0014] Add 0.2mol / L 3-hexylthiophene monomer into 50mL deionized water, add 40gL -1 KI and 10gL -1 MnI 2 , ultrasonically stirred to form an emulsion; 50mL 2mol / L ferric chloride aqueous solution was slowly added to the first solution, and the stirring was continued during the addition process. After standing at 50°C for 12 hours, a precipitate was obtained, and MnO was obtained by filtration, washing and drying. 2 Loaded poly-3-alkylthiophene powder. Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When the electrolyte on the two electrodes is in a semi-dry state, paste the two electrodes face to face, and dry to obtain a full solid state. Symmetrical supercapacitor with a specific capacity of 420Fg -1 .

Embodiment 3

[0016] Add 0.1mol / L 3-dodecylthiophene monomer into 50mL deionized water, add 30gL -1 KI and 5gL - 1 MnI 2 , ultrasonically stirred to form an emulsion; 50mL 1.8mol / L ferric chloride aqueous solution was slowly added to the first solution, stirring was continued during the addition process, and after standing at room temperature for 24 hours, a precipitate was obtained, and MnO was obtained by filtering, washing and drying. 2 Loaded poly-3-alkylthiophene powder. Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When the electrolyte on the two electrodes is in a semi-dry state, paste the two electrodes face to face, and dry to obtain a full solid state. Symmetrical supercapacitor with a specific capacity of 479Fg -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com