Preparation method of MnO2-supported TiO2 one-dimensional nano-material

A technology of nanomaterials and products, which is applied in the field of preparation of MnO2-loaded TiO2 one-dimensional nanomaterials, which can solve the problems of poor mechanical strength, low porosity, and many active components, and achieve cheap raw materials, simple processes, and control of structure and morphology stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

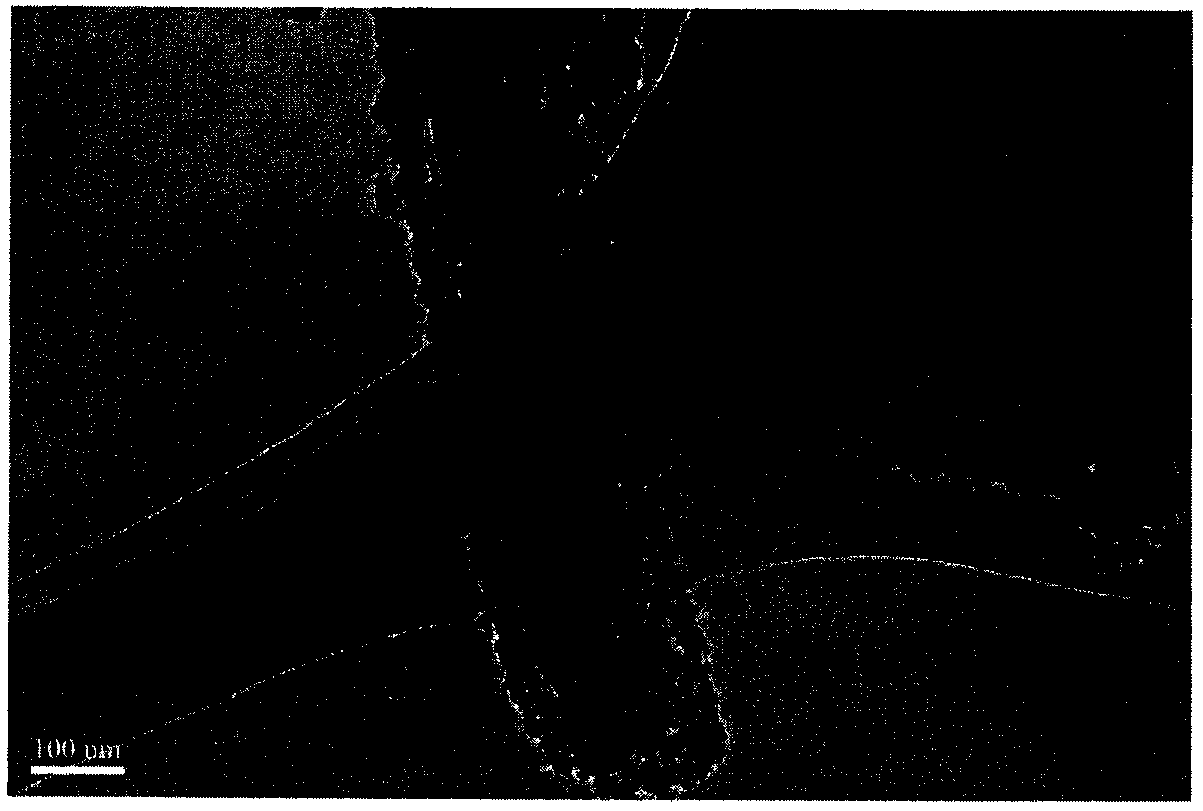

Image

Examples

Embodiment 1

[0018] First, add 0.8mol sodium hydroxide and 6mmol nano-titanium dioxide into 80mL deionized water, stir evenly, then transfer the mixed solution into a hydrothermal reaction kettle with polytetrafluoroethylene, tighten the seal, and put it in a constant temperature oven at 180°C for static reaction 6 hours; then the reaction product was washed repeatedly with deionized water until the pH value was 8; then washed 4 times with 0.2 mol / L hydrochloric acid; after drying, metatitanic acid nanobelts were obtained. Ultrasonic dispersion of 0.3 g of metatitanic acid nanobelts into 100 mL of 0.04 mol / L MnCl 2 To the solution, add 100mL of 0.06mol / L ammonium persulfate aqueous solution dropwise, and continue to stir for 6 hours, alternately wash with deionized water and ethanol, filter with centrifuge precipitation after each washing, wash and dry to obtain manganese oxide material loaded metatitanic acid powder. After drying, the powder was calcined in a muffle furnace at 700°C for ...

Embodiment 2

[0020] First, add 0.8mol potassium hydroxide and 6mmol nano-titanium isopropoxide into 80mL deionized water, stir evenly, then transfer the mixed solution into a hydrothermal reaction kettle with polytetrafluoroethylene, tighten the seal, and put it in a constant temperature oven at 150°C Stand for reaction for 6 hours; then the reaction product was washed repeatedly with deionized water until the pH value was 8; then washed 4 times with 0.2 mol / L hydrochloric acid; and metatitanic acid nanobelts were obtained after drying. Ultrasonic dispersion of 0.3 g of metatitanic acid nanobelts into 100 mL of 0.04 mol / L MnSO 4 Add 100mL of 0.06mol / L potassium persulfate aqueous solution dropwise to the solution, and keep stirring for 12 hours, alternately wash with deionized water and ethanol, filter with centrifuge precipitation after each washing, wash and dry to obtain manganese oxide material loaded metatitanic acid powder. After drying, the powder was calcined in a muffle furnace a...

Embodiment 3

[0022] First, add 0.8mol potassium hydroxide and 6mmol nano-titanium dioxide into 80mL deionized water, stir evenly, then transfer the mixed solution into a hydrothermal reaction kettle with polytetrafluoroethylene, tighten the seal, and put it in a constant temperature oven at 180°C for static reaction 6 hours; then the reaction product was washed repeatedly with deionized water until the pH value was 8; then washed 4 times with 0.2 mol / L hydrochloric acid; after drying, metatitanic acid nanobelts were obtained. Ultrasonic dispersion of 0.3 g of metatitanic acid nanobelts into 100 mL of 0.04 mol / L MnCl 2 Add 100mL of 0.06mol / L sodium persulfate aqueous solution dropwise to the solution, and continue to stir for 8 hours, alternately wash with deionized water and ethanol, filter with suction filtration equipment after each washing, wash and dry to obtain manganese oxide material loaded metatitanic acid powder. After drying, the powder was calcined in a muffle furnace at 700°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com