Preparation of Nano-SnO2 Loaded Polyα-Naphthylamine Nanotube Gas Sensing Materials

A technology of nano-tin dioxide and gas-sensitive sensing materials, applied in the field of material chemistry, can solve the problems of in-situ modification of polymer materials and harsh synthesis environment, etc., and achieve stable structure and morphology control, simple process, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, nanometer SnO The chemical preparation method of loaded poly α-naphthylamine nanotube:

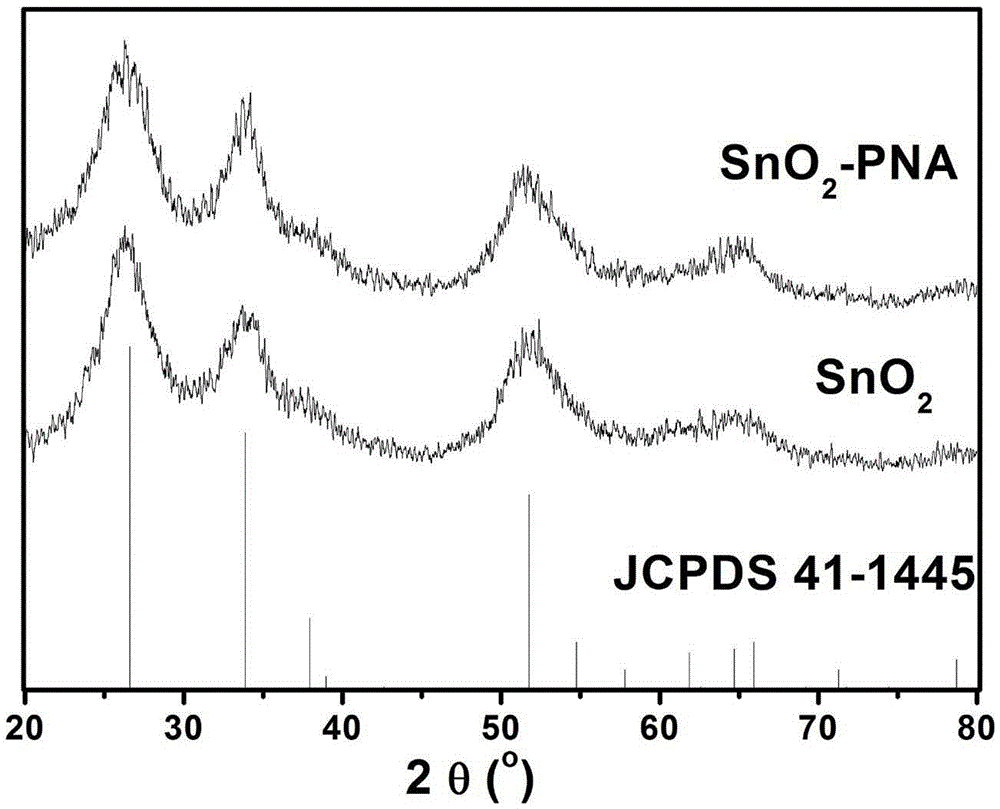

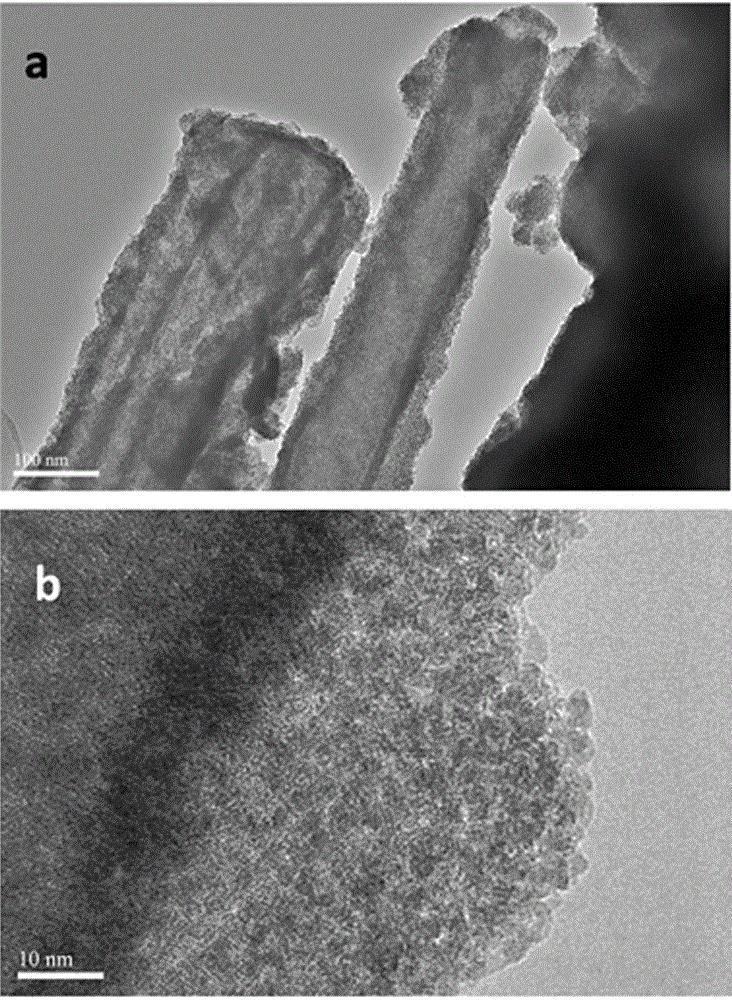

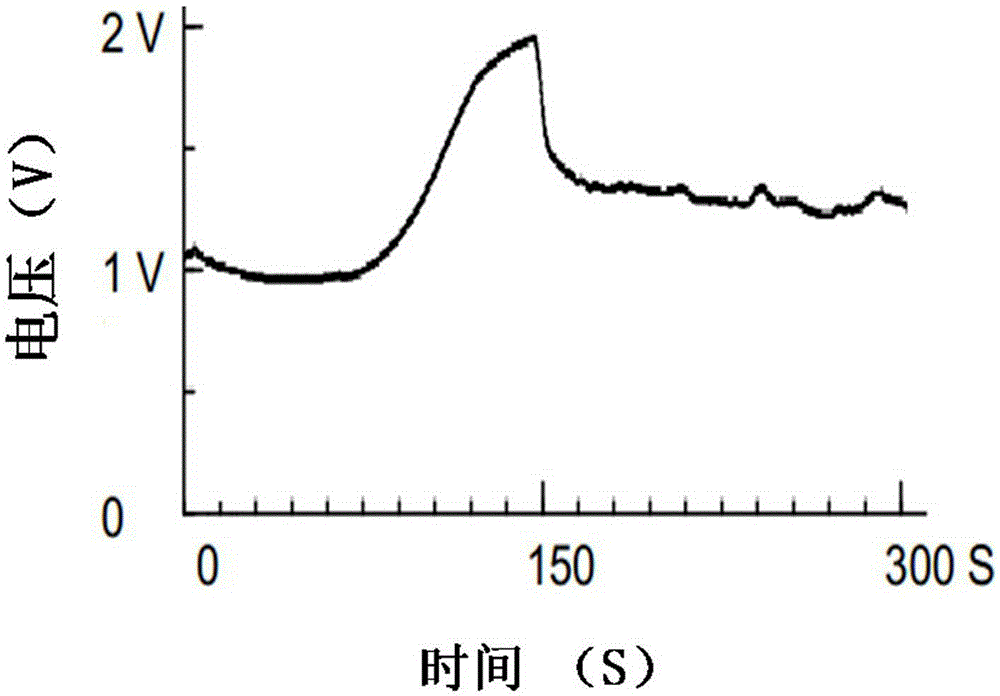

[0021] First, 2 mmol of α-naphthylamine monomer, 4 mmol of stannous chloride and 10 mmol of b-naphthalenesulfonic acid were added to 50 mL of deionized water and stirred to form an emulsion. Another 20mmol of potassium persulfate was dissolved in 50mL of deionized water and added to the previously prepared emulsion at a rate of two seconds per drop, the color of the mixture gradually turned blue and then turned brown. The mixed solution was continuously stirred at room temperature for 24 hours, and a black precipitate formed at the bottom of the cup. The resulting product was alternately washed with deionized water and ethanol several times to neutrality, and placed in an oven at 60°C for 8 hours to dry to obtain SnO 2 Supported poly-α-naphthylamine nanotubes. Product XRD patterns such as figure 1 shown, with SnO 2 The standard spectrum (JCPDS card: 41-1445) corres...

Embodiment 2

[0024] Repeat embodiment 1, adopt stannous sulfate to replace tin protochloride, obtain SnO 2 Supported poly-α-naphthylamine nanotubes. The sensitive element prepared from this material has a sensitivity of 1.2 in 10 ppm ammonia gas at room temperature.

Embodiment 3

[0026] Repeat embodiment 1, adopt 10% hydrogen peroxide to replace ammonium persulfate aqueous solution, obtain SnO 2 Supported poly-α-naphthylamine nanotubes. The sensitive element prepared from this material has a sensitivity of 1.4 in 10 ppm ammonia gas at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com