Synthetic method of manganese oxide-loaded polypyrrole nanotube

A technology of polypyrrole nanotube and manganese oxide is applied in the field of material chemistry to achieve the effects of simple process, stable structure and morphology control, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Dissolve 0.001mol of MnCl2 and 0.004mol of pyrrole monomer in 50mL of acidic aqueous solution (pH=1), add 0.0005mol of methyl orange; dropwise add 50mL of aqueous solution containing 0.01mol of ammonium persulfate, and continue stirring for 8 hours at room temperature , a black precipitate was obtained after the reaction. Alternately wash with deionized water and ethanol. After each washing, use centrifuge sedimentation or suction filtration equipment to filter. The filtered product is redispersed in deionized water or ethanol. Repeatedly filter until the pH of the filtrate is 7. Place in a vacuum oven at 50°C Dry to obtain manganese oxide-loaded polypyrrole nanotubes, and the SEM photos are as follows: figure 1 shown.

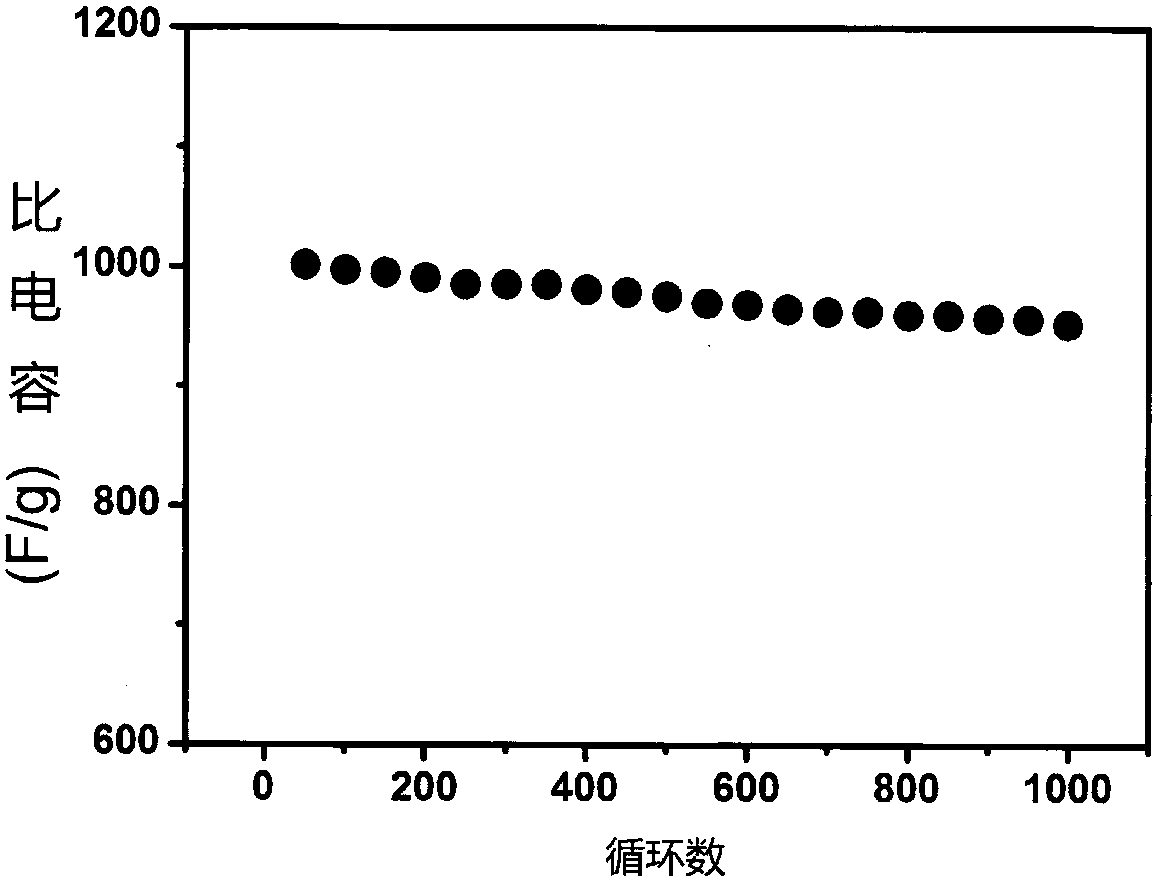

[0015] Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When t...

Embodiment 2

[0017] 0.005mol MnCl and 0.02mol pyrrole monomer were dissolved in 50mL acidic aqueous solution (pH=1), and 0.0005mol methylene blue was added; 50mL of aqueous solution containing 0.05mol ammonium persulfate was added dropwise thereto, and the stirring reaction was continued for 8 hours at room temperature. A black precipitate was obtained. Alternately wash with deionized water and ethanol. After each washing, use centrifuge sedimentation or suction filtration equipment to filter. The filtered product is redispersed in deionized water or ethanol. Repeatedly filter until the pH of the filtrate is 7. Place in a vacuum oven at 50°C drying to obtain manganese oxide-loaded polypyrrole nanotubes.

[0018] Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When the electrolyte on the two electrodes ...

Embodiment 3

[0020] Dissolve 0.003mol MnSO4 and 0.02mol pyrrole monomer in 50mL acidic aqueous solution (pH=1), add 0.0005mol methyl orange; dropwise add 50mL aqueous solution containing 0.04mol potassium persulfate, and continue stirring at 60°C for 12 Hours, a black precipitate was obtained after the reaction. Alternately wash with deionized water and ethanol. After each washing, use centrifuge sedimentation or suction filtration equipment to filter. The filtered product is redispersed in deionized water or ethanol. Repeatedly filter until the pH of the filtrate is 7. Place in a vacuum oven at 60°C drying to obtain manganese oxide-loaded polypyrrole nanotubes.

[0021] Coat the prepared powder on the PET film with PVDF as the binder, and then evenly coat a layer of PVA / H 3 PO 4 Gel electrolyte, cut into two 5cm×8cm sheets of the same size, and use them as positive and negative electrodes respectively. When the electrolyte on the two electrodes is in a semi-dry state, paste the two elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com