Method for brewing juicy peach baijiu

A technology of peach and flavor type, which is applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc. It can solve the problems that cannot be solved such as excessive methanol in peach wine, and achieve the effect of strong aroma and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

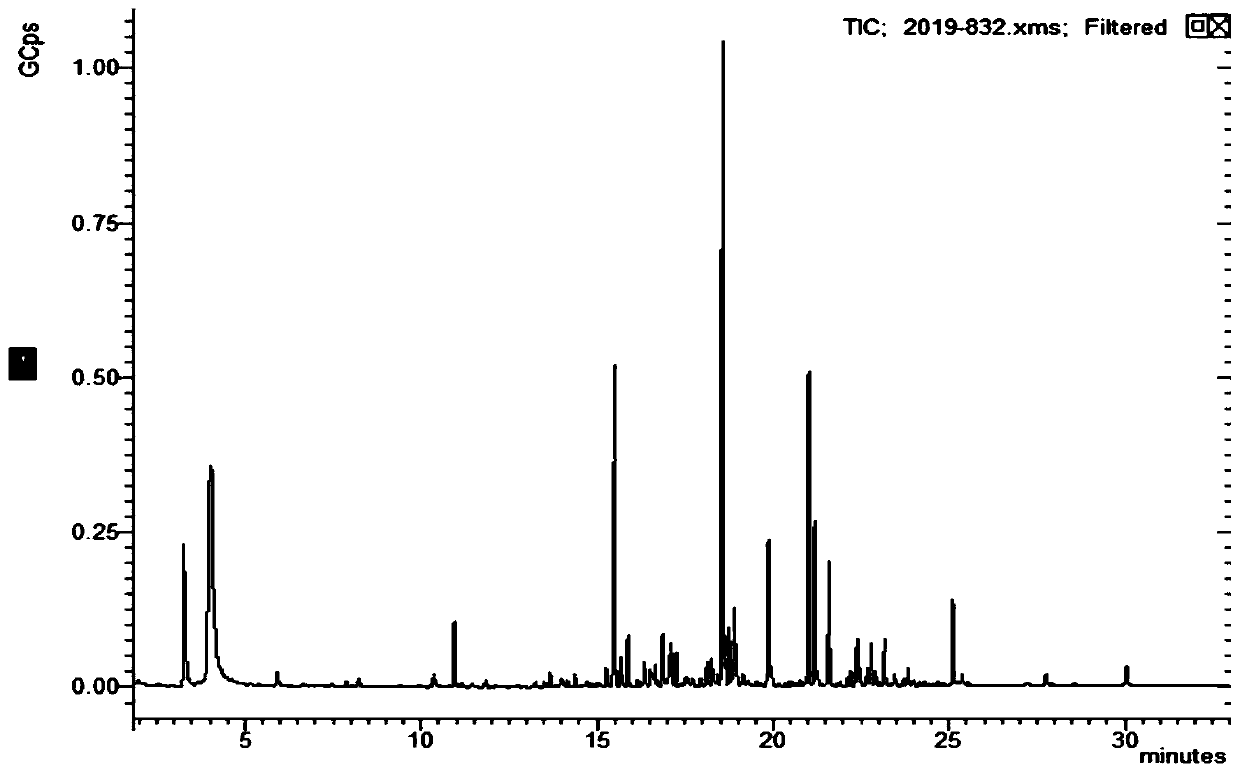

Image

Examples

Embodiment 1

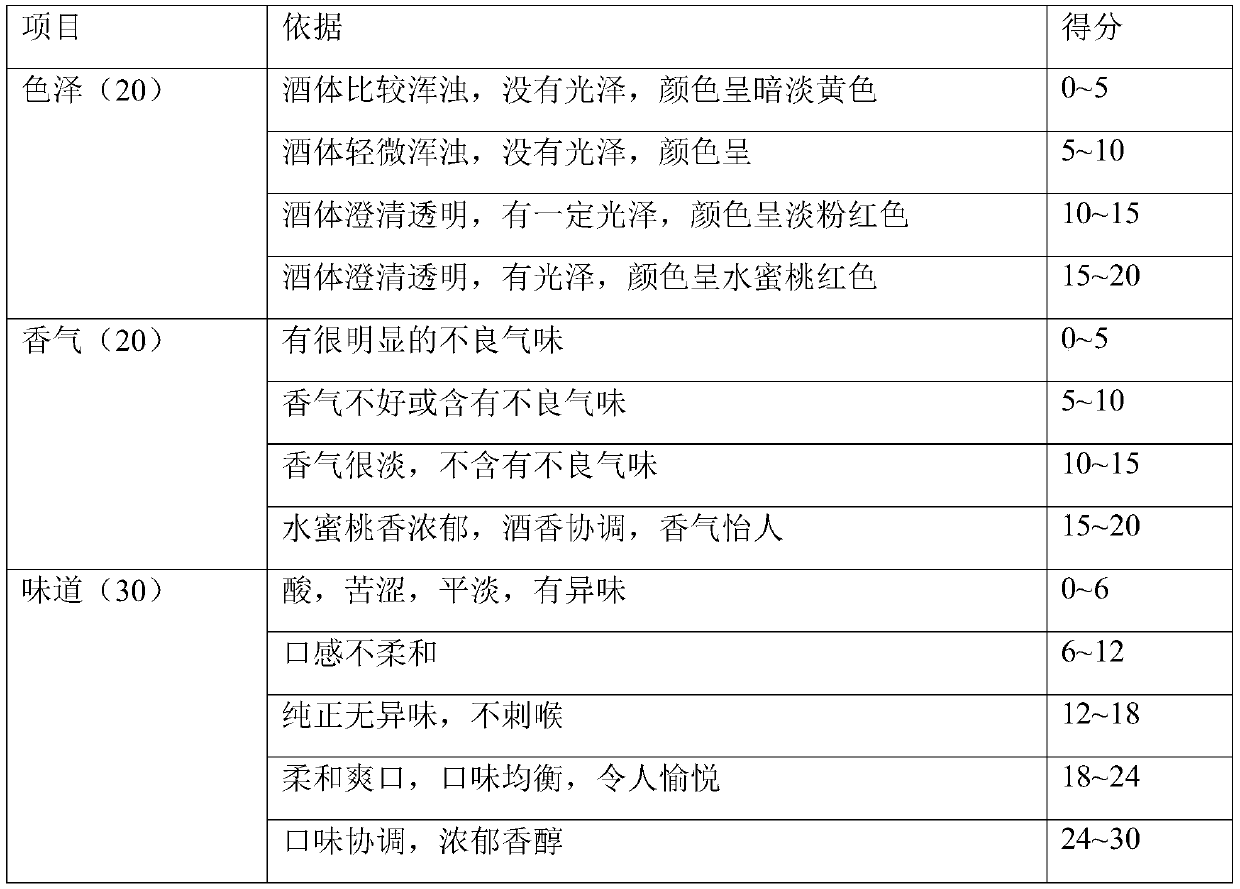

[0035] Fresh peaches are processed by an automatic peach pitting and peeling machine MDJ1-2.5 to obtain peach puree. The peach puree is added with rock sugar to adjust the sugar content to 26BX. It is divided into three barrels for fermentation. Barrel A is fermented with Saccharomyces cerevisiae CICC 1383; Barrel B is fermented with two strains of yeast, Saccharomyces cerevisiae CICC 1383 and Angel Aroma yeast active dry yeast, inoculate at the same time and inoculate in equal amounts. Barrel C was co-fermented with the addition of three yeast strains. The three yeast strains were Saccharomyces cerevisiae CICC1383, Saccharomyces angelica active dry yeast, and Hansenula spp. CICC1959. Alcohol, sensory evaluation of aroma, detection of ethyl acetate.

[0036] Table 2 Comparison of single-bacteria fermentation and three-bacteria fermentation of peach puree plus rock sugar to adjust sugar content

[0037] Determination index Alcohol %(V / V) Ethyl acetate (mg / L) s...

Embodiment 2

[0039] The peach wine with an alcohol concentration of 13.5% is distilled into 35% crude distilled liquor; the crude distilled liquor is distilled again into "original peach liquor" with an average alcohol content of 58 degrees. Put it in 50 tons of stainless steel and store it for half a year, alcoholize with intermittent aeration, and the alcohol content will be 55% after half a year.

Embodiment 3

[0041] The peach liquor obtained in Example 2 was treated with 0.2% added amount of coconut shell activated carbon particles for food grade wine for 24 hours to remove impurities and turbidity, and then pass through composite molecular sieve (4A+5A molecular sieve) and wine polymer resin (Macroporous Adsorbent Resin HPD600) Continuous methanol removal and impurity removal treatment, the liquor is translucent. The alcohol content, methanol content, and ethyl acetate content before and after treatment are shown in Table 3.

[0042] Table 3 Peach liquor coconut shell activated carbon, composite molecular sieve and wine polymer materials

[0043] Determination index Alcohol %(V / V) Ethyl acetate (mg / L) Methanol (mg / L) before processing 55 556 1610 after treatment 54.6 360 815 Comparative example 1 54.3 356 918 Comparative example 2 53.4 317 1256 Comparative example 3 53.8 243 967

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com