Method for producing bioethanol through coffee waste

A bioethanol, waste technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as fossil fuel pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

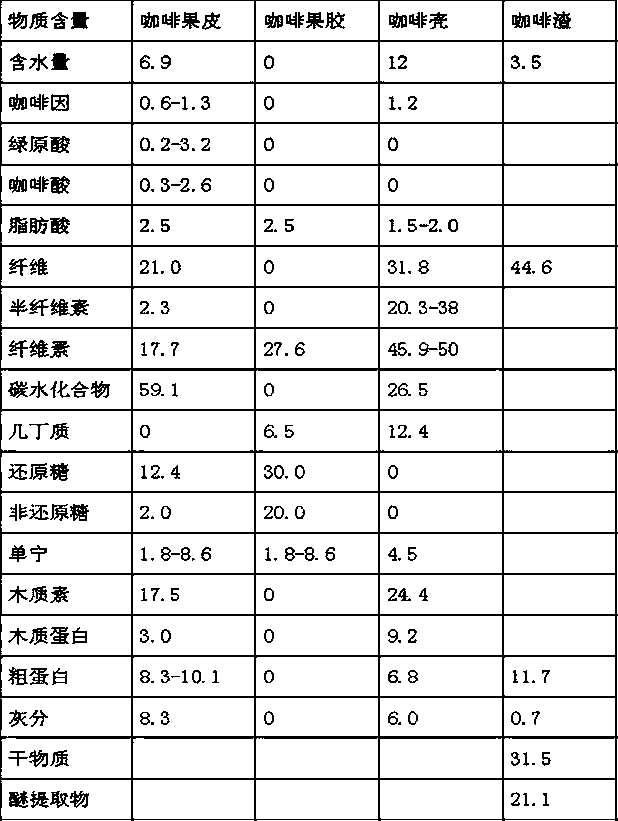

[0025] The composition of coffee waste was analyzed, and the results are shown in Table 1.

[0026] Table 1 Composition of coffee waste materials

[0027]

[0028] The coffee peel may contain coffee peel or coffee peel + pectin + shell.

Embodiment 2

[0030] A. Acid hydrolysis: add sulfuric acid in deionized water, the concentration of sulfuric acid is 0.4-0.6 M, then add coffee waste, the ratio of coffee waste to water is (kg / L)=1:3-1:5, temperature Stir for 1 hour at 100°C;

[0031] B. Enzymolysis: lower the coffee waste acid hydrolysis solution to room temperature, adjust the pH value to 4-5, control the temperature at 30-37°C, add yeast, and ferment for 48-96 hours to obtain coffee waste enzymatic hydrolysis solution ;

[0032] C. Distillation: Distill the coffee waste enzymatic hydrolysis solution at 75-85°C and cool to obtain bioethanol.

[0033] The source of Pichia anomaly is the Pichia anomaly that degrades the coffee rind efficiently and is re-isolated from commercial strains domesticated by the China Coffee Engineering Research Center in the fermentation of coffee rinds. Pichia anomala CERCC No. 3.

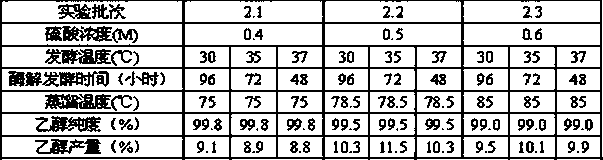

[0034] According to this method, experiment is carried out, and each parameter and ethanol yield are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com