Process for producing LF slagging agents by using electrolytic aluminum carbon slag

A production process and slag-reducing agent technology, applied in the field of LF slag-reducing agent production, can solve the problems of producing LF slag-reducing agent without major slag repairing of electrolytic aluminum, achieve full resource utilization, contribute to environmental protection and, The effect of reducing mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

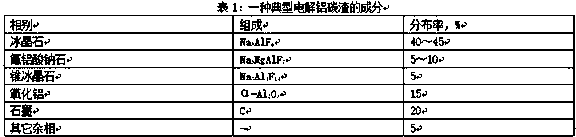

[0053] A kind of technology that utilizes electrolytic aluminum carbon slag to produce LF deslagging agent, production technology is as follows:

[0054] 1) According to the principle of mechanochemical reaction, the carbon slag produced by electrolytic aluminum is processed to a particle size of 0.5-1.5 mm by using a ball mill, so that it has good chemical reactivity;

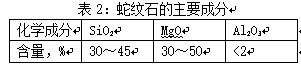

[0055] 2) buy calcined serpentine powder, the weight percentage content of this serpentine powder is: SiO 2 30-45%, MgO 30-50%, Al 2 o 3 <2%, the particle size is controlled at 3-5mm, and it is used as aggregate for pelletizing;

[0056] 3) Mix the above materials evenly according to the ratio of 87:10 by mass percentage, and then add 3% MgCl as a binder;

[0057] 4) Use a dry powder briquetting machine to press the above materials into 30-50mm slag-removing agent spheres. The mass percentages of the components of the slag-removing agent spheres are as follows: MgO30, SiO 2 <5, Na<25;

[0058] 5) Pull an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com