Low-calorie cereal bar composition

A technology of composition and grain, applied in the direction of food science, food ingredients as taste improvers, food ingredients as water activity improvers, etc., can solve problems such as hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] Preparation Example 1: Preparation of Allulose Powder

[0041] As psicose, psicose syrup is prepared from a fructose substrate by a biological method substantially the same as that disclosed in Korean Patent No. 10-16173797.

[0042] Specifically, the coding gene (DPE gene; gene bank: EDS06411.1) of Clostridium scindens (Clostridium scindens) (Clostridium scindens ATCC 35704) derived from psicose epimerase was introduced into the recombinant vector (pCES_sodCDPE) , and use the prepared recombinant vector (pCES_sodCDPE) plasmid to transform into Corynebacterium glutamicum by electroporation. Prepare the beads that comprise the Corynebacterium glutamicum cells of transformation and fill in the immobilization reaction column, obtain glucose: fructose: psicone: oligosaccharide=6:67:25:2 of 24~ 26 (w / w) % glucose syrup.

[0043] In order to remove impurities such as colored and ionic components, at room temperature, flow through the resin filled with cation exchange resin,...

Embodiment 1 and 2

[0045] Examples 1 and 2: Preparation of cereal bars using psicose powder

[0046] 1-1: Preparation of syrup

[0047] The preparation of syrup for the production of cereal bars is carried out by weighing the ingredients and adding the appropriate amount of water. Syrup for cereal bar production is prepared by heating the syrup using a water double boiler, evaporating the water in the syrup to adjust a certain syrup Brix (82bx). Syrup solutions were prepared with the components and amounts shown in Table 1.

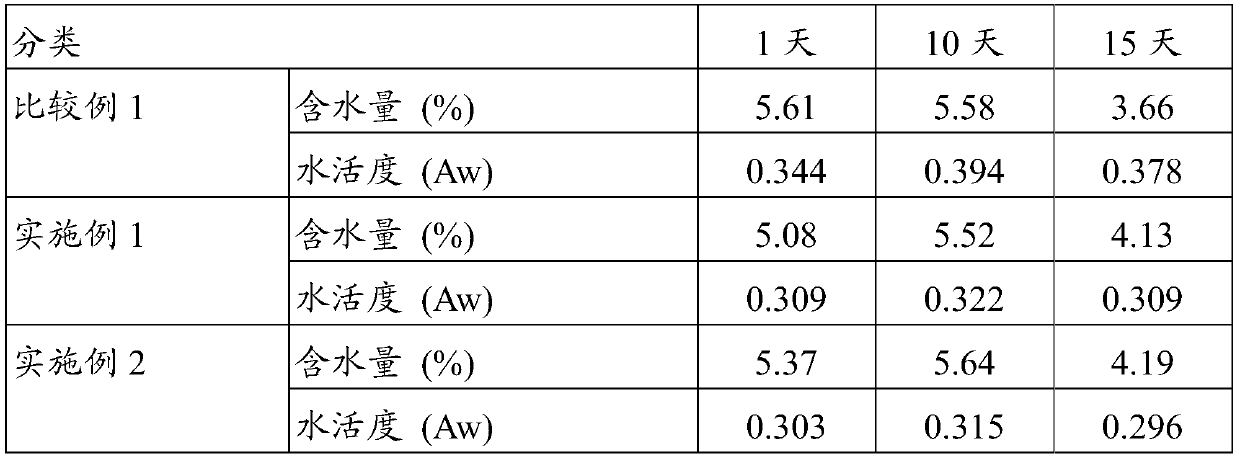

[0048] [Table 1]

[0049] raw material Comparative Example 1 (% by weight) Embodiment 1 (weight %) Embodiment 2 (weight %) Starch Syrup (82bx) 40 40 40 sucrose 40 20 - Isomaltooligosaccharide 20 20 20 Allulose Powder - 20 40 total 100 100 100

[0050] 1-2: Preparation of cereal bars

[0051] The prepared syrup for the cereal bars was mixed with the ingredients and amounts shown in Table 2 and heated in a pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com