Preparation method of reducible resistant dextrin

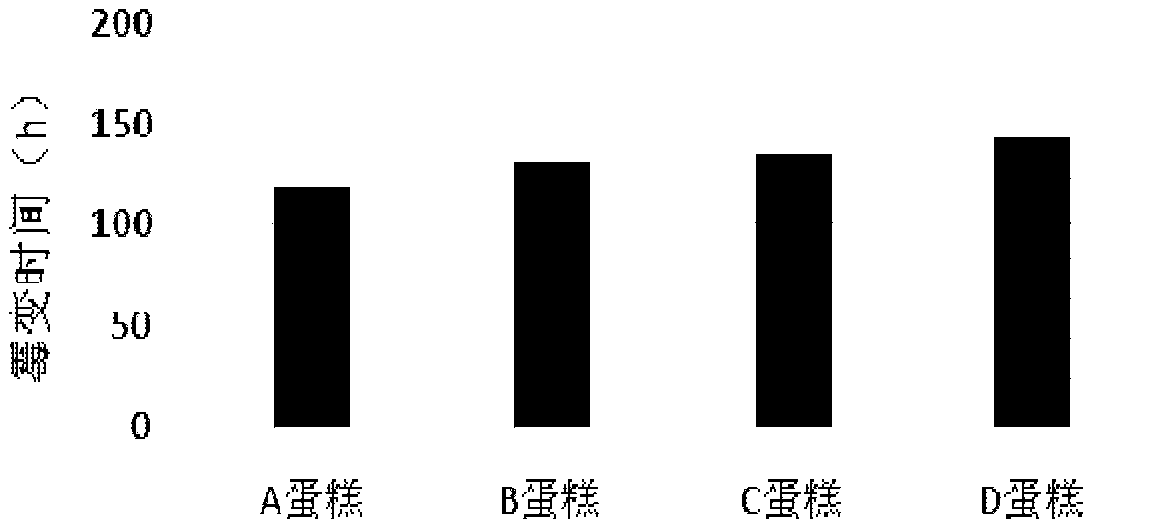

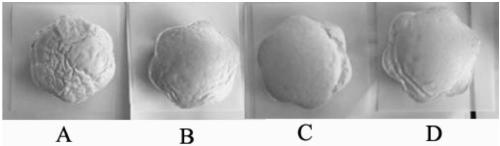

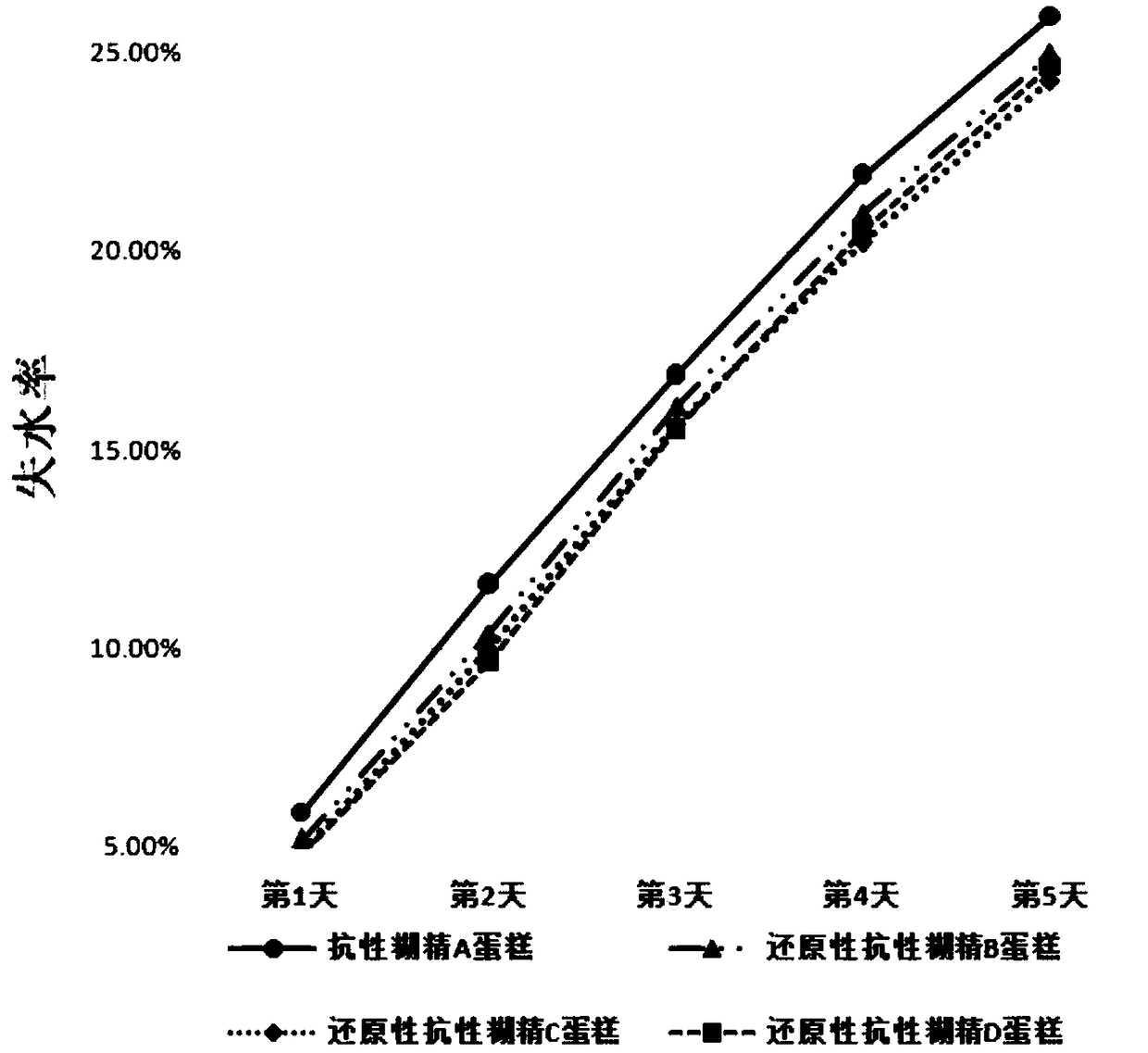

A technology of resistant dextrin and mass fraction, applied in the field of food additives, can solve the problems of unfavorable food storage, short shelf life, high water activity of resistant dextrin, etc., to improve moisturizing performance, inhibit digestion and absorption, and benefit storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of reducing resistant dextrin, the steps are as follows:

[0047] (1) taking cornstarch as raw material, adding tap water to adjust to be 17% starch milk with dry starch mass fraction;

[0048] (2) Adjust the pH of the starch milk to 6.0 with dilute hydrochloric acid with a mass fraction of 15% in step (1), and add high-temperature-resistant α-amylase in an amount of 1.8×10 7 U / ton of dry starch, heating up to 100°C, heat preservation reaction for 20min, to obtain a liquefied solution with a DE value of 8.51%;

[0049] (3) Adjust the pH of the liquefied liquid prepared in step (2) to 5.1 with dilute hydrochloric acid with a mass fraction of 15%, add fungal α-amylase and pullulanase, and the addition amount of fungal α-amylase is 1.3× 10 7 U / ton of dry starch, the amount of pullulanase added is 1.5×10 7 U / ton dry starch, heat preservation reaction at 52°C for 36h, and concentrate to a mixed solution with a mass fraction of solids of 60%;

[0050]...

Embodiment 2

[0054] A preparation method of reducing resistant dextrin, the steps are as follows:

[0055] (1) take potato starch as raw material, add tap water and adjust to dry starch mass fraction and be the starch milk of 20%;

[0056] (2) The starch milk in the step (1) is adjusted to pH 5.8 with dilute hydrochloric acid with a mass fraction of 15%, and high-temperature-resistant α-amylase is added in an amount of 1.5×10 7 U / ton of dry starch, heat up to 92°C, keep warm for 25 minutes, and obtain a liquefied solution with a DE value of 9.2%;

[0057] (3) The liquefied liquid obtained in step (2) is adjusted to pH 5.3 with dilute hydrochloric acid with a mass fraction of 15%, adding fungal α-amylase and pullulanase, and the addition amount of fungal α-amylase is 1.5× 10 7 U / ton of dry starch, the amount of pullulanase added is 1.2×10 7 U / ton dry starch, heat preservation reaction at 53°C for 40h, and concentrate to a mixed solution with a mass fraction of solids of 58%;

[0058] (4...

Embodiment 3

[0062] A preparation method of reducing resistant dextrin, the steps are as follows:

[0063] (1) take wheat starch as raw material, add tap water to adjust into dry starch mass fraction and be the starch milk of 23%;

[0064] (2) Adjust the pH of the starch milk in step (1) to 6.2 with dilute hydrochloric acid with a mass fraction of 15%, and add high-temperature-resistant α-amylase in an amount of 2.0×10 7 U / ton of dry starch, heat up to 95°C, keep warm for 18 minutes, and obtain a liquefied solution with a DE value of 10.8%;

[0065] (3) The liquefied liquid obtained in step (2) is adjusted to pH 5.5 with dilute hydrochloric acid with a mass fraction of 15%, and fungal α-amylase and pullulanase are added, and the amount of fungal α-amylase added is 1.8× 10 7 U / ton of dry starch, the amount of pullulanase added is 1.8×10 7 U / ton dry starch, heat preservation reaction at 54°C for 42h, and concentrate to a mixed solution with a mass fraction of solids of 63%;

[0066] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com